Linear DC Welder

AIT offers the AVIO line of ultra precision Transistor Welders

Advanced Integrated Technologies ( AIT ) is a resistance welding equipment and technical support provider for Nippon Avionics ( Avio ) brand of resistance spot welders and accessories as well as Sunstone brand spot welders. We can evaluate your product samples, provide free test welds, and accurately specify which equipment is best for your application. We can then provide the equipment you need at an economical price, and assist with any technical issues you encounter setting up your welding process. Submit a contact form or call us today to request assistance with your next project.

Providing you with equipment and technical support

Lower prices on equipment and electrodes than other manufacturers

Shorter lead time, especially on electrodes

Free test welds and unparalleled customer support

How We Can Help You

Advanced Integrated Technologies ( AIT ) offers you free test welds to help determine if an inverter welder is the proper equipment for your application. We are a equipment and technical support provider for Nippon Avionics ( Avio ) brand of precision inverter welders. At AIT, we have chosen the AVIO line of equipment because you get more advanced technology, quality, and precision for your money than with other popular brands. We can provide the equipment you need at an economical price, and assist with any technical issues you encounter setting up your welding process. Submit a contact form or call us today to request assistance with your next project.

Click here for matching weld heads.

Click here for matching weld heads.

AVIO Transistor Welders

- The favorite for welding micro wires and components

- Consistent and precise welding by high speed linear control

- 3 Feedback modes (constant current, voltage, or power)

- High speed welding (up to 5 shots / second)

- Pre-weld check function reduces spark problems

- Simultaneous graph of voltage, current, and power wave forms

| Features | MCW-700 | MCW-750 |

| Maximum Current | 500A | 1800A |

| Maximum Voltage | 2V | 4V |

| Constant Current Mode | 10 - 500A (1A Step) | 10 - 1800A (1A Step) |

| Constant Voltage Mode | 0.001 - 2V (1mV Step) | 0.01 - 4V (10mV Step) |

| Constant Power Mode | 10 - 500W (1W Step) | 10 - 3600W (1W Step) |

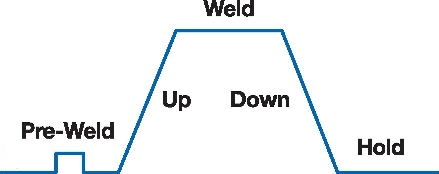

| Weld Time : Up | 0 -999 x 0.01ms or x 0.1ms | |

| Weld Time : Weld | 0 -999 x 0.01ms or x 0.1ms | |

| Weld Time : Down | 0 -999 x 0.01ms or x 0.1ms | |

| Weld Time : Squeeze&Hold | 9.99s (maximum) | 9.99s (maximum) |

| Pre-Check | Resistance/Current | Resistance/Current |

| Shot / Sec | 5shots / sec: 500W 2ms | 5 shots / sec : 3600W 2ms |

| Monitor : Wave Form | Current / Voltage / Power | Current / Voltage / Power |

| Monitor : Current | Average / Peak | Average / Peak |

| Monitor : Voltage | Average / Peak | Average / Peak |

| Monitor : Power | Average / Peak | Average / Peak |

| Number of Conditions | 15 | 15 |

| Interface | RS-232, I/O, analog output | RS-232, I/O, analog output |

| Power Source (Option) | 100-120V AC (200-240V AC) | 100-120V AC (200-240V AC) |

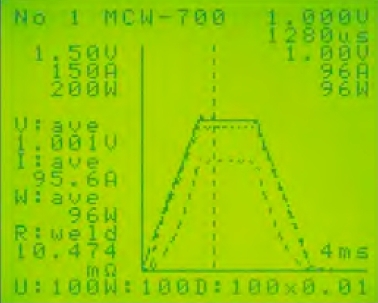

Real Time Welding Wave Form Display

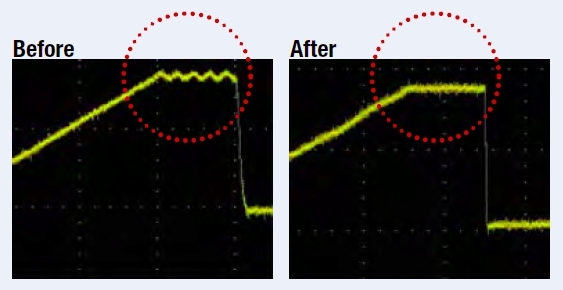

PID Adjustment - Before and After

Transistor welders are also known as Linear DC welders. In a transistor welder, energy is stored up in capacitors and released through transistors. This produces a result similar to the high frequency inverter power supplies. The output is in the form of clean square waves with very fast rise time. The transistor welders made by AVIO are closed loop designs, utilizing transistor controlled feedback with extremely fast response time, which are able to monitor the condition of the weld using one of three feed back modes, "constant current", "constant voltage", or "constant power". These feedback modes offer great advantages such as better process consistency between multiple weld stations, reduced number of bad welds, and real time automatic adjustment for variations in part thermal loading and plating. Linear DC welders do not use a transformer. These power supplies have the best low energy control, making them the favorite for welding micro wires and then foils. The major limitation is that the duty cycle is typically much less than one weld per second.

The Avio welders we are offering here are premium quality Japanese made welders. We stand by these welders and guarantee our customers support and assistance when you buy an Avio welder from us. All electrodes are manufactured by AIT in our facility in the United States. We can respond quickly to your inquiries or questions.

The Avio welders we are offering here are premium quality Japanese made welders. We stand by these welders and guarantee our customers support and assistance when you buy an Avio welder from us. All electrodes are manufactured by AIT in our facility in the United States. We can respond quickly to your inquiries or questions.

Welding Wave Form

Sunstone has designed a completely unique closed-loop feedback resistance welding system that utilizes new technologies, giving the UC Linear DC welder the power of a High-Frequency Inverter and the precision of a Linear DC. It does not require an external transformer, so it isn’t an HF welder, and it offers a greater range of settings than a typical Linear DC welder, yet is able to perform the same functions as both, and in most cases exceed those of other HF or Linear DC welders – offering high repetition rates, fine low-energy control, and short or long weld times – without drawbacks.

The welder is highly adjustable to offer the most convenience to a wide variety of users allowing creation of custom software, ability to update and improve capabilities, features and functions effortlessly.

The UC linear DC can also introduce high-frequency agitation that provides additional weld penetration, more uniform metal crystallization, stronger weld joints, and can facilitate stronger weld joints with lower overall heat input.

Applications include

•Thermocouples

•Battery Pack Welding

•Coil Termination

•Relays

•Strain Gauge

•Aerospace Welding

•Honeycomb

•PCB Welding

•Electrical Components

•Sensors

•Injectors

•Magnet Wire Bonding

•Solenoids

•Transformer Coils

•Actuators

•Inductors

•Seam Welding

•Adding Material

•And More!

Features

•10-2500A weld current

•Roll Spot Capability

•Short Seam Segments

•Geared for Automation

•Weld data logging

•High precision linear DC welder

•No external transformer required

•Programmable Schedules and Jobs

•10” Capacitive Touch screen Interface

•Closed loop feedback and weld monitoring technology

•Graphical feedback display of current, power and voltage

•Updateable firmware

•Dual weld control

•LVDT (position) Feedback

•Force Feedback

•Data logging via USB and ethernet

•Smart heat weld overlay

•Customizable waveform generation

•Fine control over energy waveform

| LDC 1500W | LDC 3000W | |||

|

Nominal Line Voltage (Single Phase)

|

90-264 AC Version

|

180-264V

|

||

|

Duty Cycle

|

4%

|

8%

|

||

| Current |

10A -2500A 10 Amp/Step

|

10A -2500A 1 Step

|

||

| Voltage |

0.1V - 10.0 V at 10 mV/Step

|

0.1V - 10.0 V at 10 mV/Step

|

||

| Power |

0.01kW - 20kW 10Watt/Step

|

0.01kW - 20kW 10Watt/Step

|

||

|

Peak Current

|

2500 A

|

2500 A

|

||

|

Peak Voltage

|

10V

|

10V

|

||

|

Peak Power

|

20kW

|

20kW

|

||

|

Weld Period Ranges

weld time (each section)

Squeeze/Hold Periods

|

Ranges (msec)

0-100

0-5

|

Resolution (steps)

0.1 ms

1 ms

|

Ranges (msec)

0-100

0-5

|

Resolution (steps)

0.1 ms

1 ms

|

|

Current Output Accuracy

|

±10A

|

±10A

|

||

|

Voltage Output Accuracy

|

± 0.005V

|

± 0.005V

|

||

|

LxWxH

|

15.2x11.4x15.5in (38.5x28.9x39.3cm)

|

15.2x11.4x15.5in (38.5x28.9x39.3cm)

|

||

|

Weight

|

46.5 lbs (21.1kg)

|

46.5 lbs (21.1kg)

|

||

The DC 5 is a precision DC waveform welding power supply, capable of precise power delivery. It has a maximum output of 5 volts, and can be adjusted to deliver as low as 0.1 volts. It has a digital readout that shows the weld length and volts delivered. The DC 5 is able to deliver up to 60 welds per minute. This unit is excellent for fine wires and metal sheets, such as ribbons. The DC 5 is the perfect choice for control and precision.

Sunstone’s micro welding solutions are perfect for microjoining and thermocompression bonding. When bonding small wires or ribbon from one connection pad to another, Sunstone’s new DC 5 - welder in combination with a low-force micro weld head is recommended as an optimal welding setup.

Applications

- Thermocompression and Microjoining Bonding

- Magnet Wire Welding

- Enamel Coated Wires

- Wire to Chip Welds

- Solar Panels

- Fine Wires and Ribbons

Features

- DC Waveforms

- Fine control of weld voltage

- Discharge Length

Peak weld current and External Cabling Gauge Number (AWG). Four and eight AWG cabling is typically seen when using hand held attachments.

|

DC Mode

|

|

|

TCB Electrode Pk Current Max

|

400A (500A w/ Larger Cabling)

|

|

TCB Electrode Pk Current Min

|

8A (5A w/ Smaller Cabling)

|

Weld Speeds

| DC Mode | |

|

Rep Rate

|

35 welds/min @ 5v 100ms

|

|

Rep Rate

|

190 welds/min @ 2v 50ms

|

Weld Pulse Characteristics

| DC Mode | |

|

Min Output

|

0.1V

|

|

Max Output

|

5V

|

|

Pulse Width Min

|

0.5 m

|

|

Pulse Width MaX

|

500 ms

|

|

Rise Time (to Max Voltage)

|

1μs

|

|

Minimum Resistance

|

8 mOhm

|

Welder Physical Characteristics

| DC 5v | ||

| Inches | cm | |

| Height | 8 |

20.3

|

| Width |

8.5

|

21.6

|

| Depth |

11

|

28

|

| Weight |

17 lbs

|

8 kg

|