Micro Spot Welder

AIT Offers the AVIO line of Ultra Precision Micro Spot Welders

Providing you with equipment and technical support

Lower prices on equipment and electrodes than other manufacturers

Shorter lead time, especially on electrodes

Free test welds and unparalleled customer support

How We Can Help You

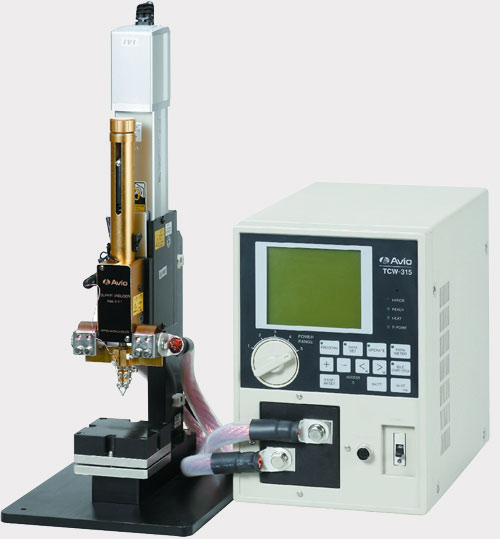

A great way to prepare for purchasing a welder is to take advantage of our free test welds to help you decide if a transistor welder is the proper weld equipment for the task. We are an equipment and technical support provider for Nippon Avionics ( Avio ) brand of precision inverter welders. At AIT, we have chosen the Nippon Avionics ( AVIO ) line of equipment because we have found that you recieve more advanced technology, quality, and precision for your money than with other brands. We can provide the equipment you need at an economical price, and assist with any technical issues you encounter. Submit a contact form or call us today to request assistance with your next project.

AVIO Micro Spot Welders

- The best choice for welding micro wires and components

- Accurate and consistent welding using high speed linear control

- Three Operation Feedback modes (constant current, voltage, or power)

- High speed welding (up to 5 shots / second)

- Pre-weld check function reduces spark problems

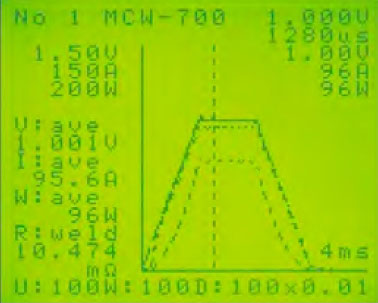

- Voltage, current, and power wave forms displayed simultaneously in a graph

| Features | MCW-700 | MCW-750 |

| Maximum Current | 500A | 1800A |

| Maximum Voltage | 2V | 4V |

| Constant Current Mode | 10 - 500A (1A Step) | 10 - 1800A (1A Step) |

| Constant Voltage Mode | 0.001 - 2V (1mV Step) | 0.01 - 4V (10mV Step) |

| Constant Power Mode | 10 - 500W (1W Step) | 10 - 3600W (1W Step) |

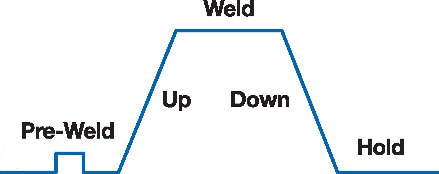

| Weld Time : Up | 0 -999 x 0.01ms or x 0.1ms | |

| Weld Time : Weld | 0 -999 x 0.01ms or x 0.1ms | |

| Weld Time : Down | 0 -999 x 0.01ms or x 0.1ms | |

| Weld Time : Squeeze&Hold | 9.99s (maximum) | 9.99s (maximum) |

| Pre-Check | Resistance/Current | Resistance/Current |

| Shot / Sec | 5shots / sec: 500W 2ms | 5 shots / sec : 3600W 2ms |

| Monitor : Wave Form | Current / Voltage / Power | Current / Voltage / Power |

| Monitor : Current | Average / Peak | Average / Peak |

| Monitor : Voltage | Average / Peak | Average / Peak |

| Monitor : Power | Average / Peak | Average / Peak |

| Number of Conditions | 15 | 15 |

| Interface | RS-232, I/O, analog output | RS-232, I/O, analog output |

| Power Source (Option) | 100-120V AC (200-240V AC) | 100-120V AC (200-240V AC) |

Real Time Welding Wave Form Display

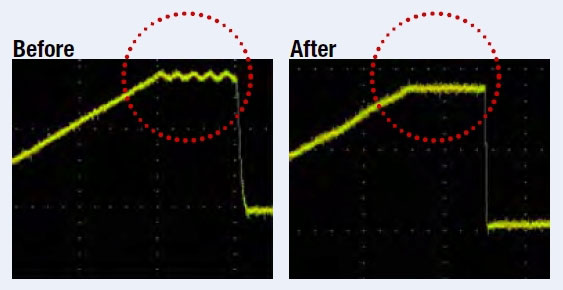

PID Adjustment - Before and After

Micro spot welders are also known as Linear DC welders. Micro spot welders load up energy in capacitors and release it through transistors. This produces a result very similar to the high frequency inverter power supplies. Clean square waves are created as the output with fast rise time. The micro spot welders made by AVIO are closed loop designs, using transistor controlled feedback with fast response time, with the ability to monitor the condition of the weld using one of three feed back modes, "constant current", "constant voltage", or "constant power". These feedback modes offer benefits such as excellent process consistency between multiple weld stations, fewer bad welds, and immediate automatic adjustment for variations in thermal loading and plating. Linear DC welders do not use a transformer. These power supplies' low energy controls are the best, making them the favorite for welding foils and micro wires. The fact that the duty cycle is typically less than one weld per second is the biggest limitation.

The Avio welders we offer are high quality Japanese welders. We stand by these welders and guarantee our customer's support and assistance when you purchase an Avio welder from us. AIT manufactures all electrodes in the U.S.A. Your questions and inquiries will be responded to quickly.

The Avio welders we offer are high quality Japanese welders. We stand by these welders and guarantee our customer's support and assistance when you purchase an Avio welder from us. AIT manufactures all electrodes in the U.S.A. Your questions and inquiries will be responded to quickly.

Welding Wave Form