3M Anisotropic Conductive Film Product Selection Guide

This slideshow is intended to help the customer choose the appropriate 3M™ Anisotropic Conductive Film (ACF) adhesive product for the job. The data included in this

graphic compare the important physical properties of the products. This product selection guide is to be used to look at the variety of products available and decide on the proper ACF (or ACFs) to each application. In the end it's best to test the application using the particular AFC product. 3M provides a variety of high-performance anisotropic conductive film adhesive products used to mechanically and electrically connect flex circuits and other components to a variety of substrates. These reliable, technologies can replace soldering and mechanical fasteners in many applications, helping to hasten assembly time and lessen space requirements.

- Product Summary

- Assembly & Application

- Design Criteria

- 3M™ ACF 5363

- 3M™ ACF 7303

- 3M™ ACF 7378

- 3M™ ACF 5552R

- 3M™ ACF 7371

- 3M™ ACF 7379

- 3M™ ACF 7393

- 3M™ ECATT 9703

- 3M™ ECATT 9705

- 3M™ ACF 7376-30

- 3M™ ACF 7376-10

- 3M™ ACF 7376-20

- 3M™ ACF 7371-20

3M™ Anisotropic Conductive Film (ACF) Adhesive 7378 is a electrically conductive, heat-bondable adhesive film. It is tacky at room temperature and is made of a thermosetting epoxy/acrylate adhesive matrix filled with conductive particles. These particles allow interconnection of circuit lines through the adhesive after bonding, but are distanced apart for the product to be electrically insulating. Heat and pressure causes the adhesive to flow and bring the circuit pads into electrical contact by trapping the conductive particles. The thermoset quickly cures. ACF 7378 can be used in bonding a flexible printed circuit to another flexible printed circuit or to a printed circuit board.

Features and Benefits

Heat cure

Thermo-set low temperature cure

Tacky at room temperature

Good thermal stability

Reworkable

Frozen storage

Product Attributes

Adhesive Thickness (metric) | 40 micron |

Adhesive Type | Epoxy/Acrylate Blend |

Application | Electronic Component Bonding, Flex Bonding |

Application Category | Bonding |

Bonding Method | Thermo-compression bonding |

Bonding Pressure | 3-4 MPa |

Bonding Temperature | 160 - 180 degree C |

Bonding Time | 5-9 seconds |

Conductive Particle Size | 10 Micron |

Conductive Particle Type | Silver-coated glass |

Connection Type | Flex to Flex, Flex to PCB |

Flex Type | Gold/Copper on Polyester, Gold/Copper on Polyimide, Silver Ink on Polyester |

Liner Thickness (metric) | 100 micron |

Liner Type | Polyester-coated Kraft with Silicone Release |

Minimum Gap | 10 mil |

Minimum Gap (metric) | 250 micron |

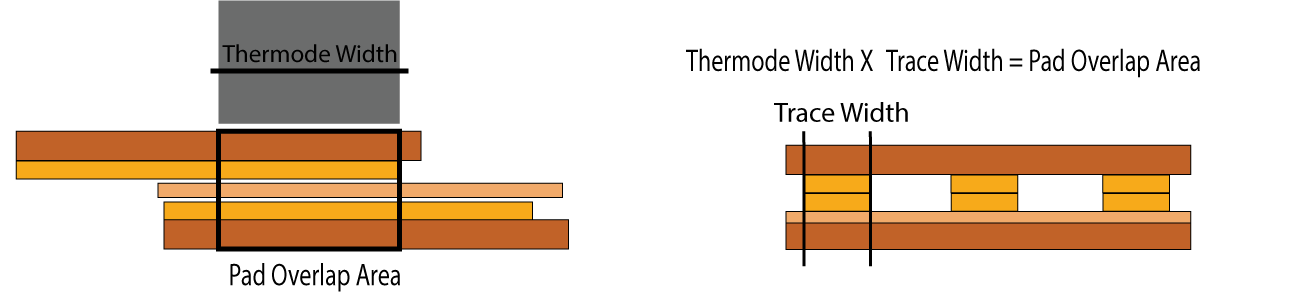

Minimum Overlap Area | 0.2 mm^2 |

Minimum Pitch | 20 mil |

Minimum Pitch (metric) | 200 Micron |

Product Form | Roll |

Product Series | 7378 |

Shelf Life | 9 Months |

Shelf Life Frozen | 18 Months |

Standard Width (metric) | 2.5 mm, 3.0 mm, 4.0 mm, 5.0 mm |

Tacking Pressure | 0.1 - 1.5 MPa |

Tacking Temperature | 25 degree C |

Tacking Time | 1 - 2 seconds |

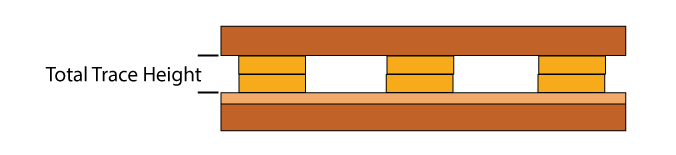

Total Trace Height (metric) | 140 micron |

3M™ Anisotropic Conductive Film (ACF) Adhesive 5552R is a electrically conductive, heat-bondable adhesive film. It is tacky at room temperature and is made of a thermosetting epoxy/acrylate adhesive matrix filled with conductive particles. These particles allow interconnection of circuit lines through the adhesive after bonding, but are distanced apart for the product to be electrically insulating. Heat and pressure causes the adhesive to flow and bring the circuit pads into electrical contact by trapping the conductive particles. The thermoset quickly cures. ACF 5552R can be used in bonding a flexible printed circuit to another flexible printed circuit or to a printed circuit board.

Features and Benefits

-

Heat cure

-

Thermo-set low temperature cure

-

Tacky at room temperature

-

Good thermal stability

-

Reworkable

-

Frozen storage

Product Attributes

|

Adhesive Thickness (metric) |

19 micron |

|

Adhesive Type |

Epoxy/Acrylate Blend |

|

Application |

Electronic Component Bonding, Flex Bonding |

|

Application Category |

Bonding |

|

Bonding Method |

Thermo-compression bonding |

|

Bonding Pressure |

2-4 MPa |

|

Bonding Temperature |

170 - 190 degree C |

|

Bonding Time |

20-30 seconds |

|

Conductive Particle Size |

6 Micron |

|

Conductive Particle Type |

Silver-coated glass |

|

Connection Type |

Flex to Flex, Flex to PCB |

|

Flex Type |

Gold/Copper on Polyester, Gold/Copper on Polyimide, Silver Ink on Polyester |

|

Liner Thickness (metric) |

100 micron |

|

Liner Type |

Polyester-coated Kraft with Silicone Release |

|

Minimum Gap |

10 mil |

|

Minimum Gap (metric) |

250 micron |

|

Minimum Overlap Area |

0.2 mm^2 |

|

Minimum Pitch |

20 mil |

|

Minimum Pitch (metric) |

100 Micron |

|

Product Form |

Roll |

|

Product Series |

5552R |

|

Shelf Life |

9 Months |

|

Shelf Life Frozen |

18 Months |

|

Standard Width (metric) |

2.5 mm, 3.0 mm, 4.0 mm, 5.0 mm |

|

Tacking Pressure |

0.1 - 1.5 MPa |

|

Tacking Temperature |

25 degree C |

|

Tacking Time |

1 - 2 seconds |

|

Total Trace Height (metric) |

140 micron |

3M™ Anisotropic Conductive Film (ACF) 7393 is a electrically conductive, heat-bondable adhesive film. The unbonded film is sticky at room temperature and is made of of a thermoset-elastomer and thermoplastic adhesive matrix packed with conductive particles. These particles allow interconnection of circuits through the adhesive, but are distanced apart for the product to be electrically insulating. Heat and pressure causes the adhesive to flow and to bring the circuit pads into electrical contact by pinning the conductive particles.The adhesive cross-links quickly at modest bonding temperature and pressure. The 3M ACF 7393 is used in bonding a flexible printed circuit to another flexible printed circuit or flexible printed circuit to polyester-based devices or flexible printed circuit to camera module devices.

Features and Benefits

-

Heat cure

-

Fast bond time

-

Thermo-set low temperature cure

-

Slight tack at room temperature

-

High adhesion to PET

-

Good thermal stability

-

Reworkable

-

Frozen storage

Product Attributes

|

Adhesive Thickness (metric) |

25 micron |

|

Adhesive Type |

Acrylate-Based |

|

Application |

Camera Module Assembly |

|

Application Category |

Bonding |

|

Bonding Method |

Thermo-compression bonding |

|

Bonding Pressure |

1 - 2 MPa |

|

Bonding Temperature |

150 - 170 degree C |

|

Bonding Time |

10 - 20 seconds |

|

Conductive Particle Size |

10 Micron |

|

Conductive Particle Type |

Gold-coated polymer |

|

Connection Type |

Flex to Camera Module, Flex to Flex, Flex to PET |

|

Flex Type |

Gold/Copper on Polyester, Gold/Copper on Polyimide, Silver Ink on Polyester |

|

Liner Thickness (metric) |

50 micron |

|

Liner Type |

Polyester Film with Silicone Release |

|

Minimum Gap |

2.5 mil |

|

Minimum Gap (metric) |

70 micron |

|

Minimum Overlap Area |

0.10 mm^2 |

|

Product Form |

Roll |

|

Product Series |

7393 |

|

Shelf Life |

4 Weeks |

|

Shelf Life Frozen |

12 Months |

|

Standard Width (metric) |

1.5 mm, 2.0 mm, 5.5 mm, 6.5 mm, 8.0 mm |

|

Tacking Pressure |

0.1 - 1.5 MPa |

|

Tacking Temperature |

60 - 90 degree C |

|

Tacking Time |

1 - 2 seconds |

|

Total Trace Height (metric) |

75 micron |

3M™ Anisotropic Conductive Film (ACF) 7376-20 is a electrically conductive, heat-bondable adhesive film. The unbonded film is sticky at room temperature and is made of of a thermoset-elastomer and thermoplastic adhesive matrix packed with conductive particles. These particles allow interconnection of circuits through the adhesive, but are distanced apart for the product to be electrically insulating. Heat and pressure causes the adhesive to flow and to bring the circuit pads into electrical contact by pinning the conductive particles.The adhesive cross-links quickly at modest bonding temperature and pressure. The 3M ACF 7376-20 is used in bonding a flexible printed circuit to another flexible printed circuit or flexible printed circuit to polyester-based devices or flexible printed circuit to camera module devices.

Features and Benefits

-

Heat cure

-

Fast bond time

-

Thermo-set low temperature cure

-

Slight tack at room temperature

-

High adhesion to PET

-

Good thermal stability

-

Reworkable

-

Frozen storage

Product Attributes

|

Adhesive Thickness (metric) |

35 micron |

|

Adhesive Type |

Acrylate-Based |

|

Application |

Camera Module Assembly |

|

Application Category |

Bonding |

|

Bonding Method |

Thermo-compression bonding |

|

Bonding Pressure |

1 - 2 MPa |

|

Bonding Temperature |

140 - 160 degree C |

|

Bonding Time |

7 - 15 seconds |

|

Conductive Particle Size |

20 Micron |

|

Conductive Particle Type |

Gold-coated polymer |

|

Connection Type |

Flex to Camera Module, Flex to Flex, Flex to PET |

|

Flex Type |

Gold/Copper on Polyester, Gold/Copper on Polyimide, Silver Ink on Polyester |

|

Liner Thickness (metric) |

50 micron |

|

Liner Type |

Polyester Film with Silicone Release |

|

Minimum Gap |

2.5 mil |

|

Minimum Gap (metric) |

70 micron |

|

Minimum Overlap Area |

0.10 mm^2 |

|

Product Form |

Roll |

|

Product Series |

7376-20 |

|

Shelf Life |

4 Weeks |

|

Shelf Life Frozen |

12 Months |

|

Standard Width (metric) |

1.5 mm, 2.0 mm, 5.5 mm, 6.5 mm, 8.0 mm |

|

Tacking Pressure |

0.1 - 1.5 MPa |

|

Tacking Temperature |

60 - 90 degree C |

|

Tacking Time |

1 - 2 seconds |

|

Total Trace Height (metric) |

75 micron |