Electrode Material

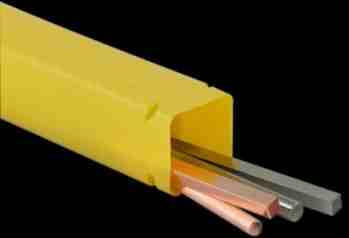

We supply Class 2 Copper, Glidcop, Molybdenum, Copper-Tungsten, and Pure Tungsten electrode materials.

Our square and round rods are typically precision ground, though a few are available as unground drawn rod. Please specify your size and required tolerance when requesting a quote.

Many more sizes and materials are available than are listed here.

| Material | Size |

|

| Glidcop | .125" diameter rod | |

| Glidcop | .250" diameter rod | |

| Glidcop | .123" x .123" square rod | |

| Molybdenum | .0625" diameter rod | |

| Molybdenum | .125" diameter rod | |

| Molybdenum | .1875" diameter rod | |

| Molybdenum | .250" diameter rod | |

| Molybdenum | .125" x .125" square rod | |

| Class 2 Copper | .125" diameter rod | |

| Class 2 Copper | .250" diameter rod | |

| Class 2 Copper | .125" x .125" square rod | |

| Tungsten | .0625" diameter rod | |

| Tungsten | .125" diameter rod |

Advanced Integrated Technologies Inc ( AIT ) supplies RWMA electrode materials used in the resistance welding and reflow soldering industries, including Glidcop and Molybdenum. Our business of manufacturing welding electrodes, reflow soldering thermodes, and hot bars has led us to stock various sizes and quantities of these exotic alloys. Glidcop is an alloy with a minimum mill order close to one thousand dollars. Many companies who wish to make their own electrodes don’t wish to buy that large a quantity of material from the mill. We sell Glidcop, Molybdenum, and many other RWMA electrode materials in sizes commonly used for micro resistance welding, and we have no minimum order quantity. Listed below are a few of the most common materials and sizes that we stock, but we have many other metals and sizes available including Berylium Copper, Copper Tungsten, Haynes 230, Nickel 200, Hastelloy, Tantalum, Inconnel 600, Inconnel 601, Inconnel 750, Monel 400, Tungsten HD17, 2% Thoriated Tungsten, and Titanium 6AL4V. Call AIT today if you need to buy Glidcop or other RWMA alloys.

Many electrode compositions are in common use in resistance welding. The choice is usually determined by the materials to be welded. AIT offers an electrode material selection chart at below. Six different electrode compositions are described below and may be ordered from AIT. The user’s selection of welding metals is not restricted, however, to those listed here.

- RWMA Class 1, Copper-Zirconium Alloy: suitable for welding aluminum alloys, magnesium alloys, coated materials, brass and bronzes.

- RWMA Class 2, Copper-Chromium Alloy: (Glidcop is often substituted for this alloy) This welding metal may be used to weld iron-base, nickel-base, cobalt-base, and chromium-base alloys. Class 2 electrodes are the most versatile general purpose alloys. AIT still builds many class 2 electrodes, but most customers are switching to Glidcop due to its superior qualities.

- RWMA Class 3, Copper-Cobalt-Beryllium Alloy: Having the same general applications as the RWMA Class 2 above, this metal sacrifices a small amount of conductivity for increased hardness. The characteristic hardness of Class 3 materials make them desirable for use as electrode-jigs and fixtures in high-production applications.

- RWMA Class 11, Copper-Tungsten Alloy: This material is used only as an insert in copper shanks. Generally, this class is used on precious metals and copper-base alloys. If sticking is evident, change to a Molybdenum or Class 13 electrode material.

- RWMA Class 13, Tungsten: Also used as an insert in a copper shank, Class 13 metals are used for copper, copper-base alloys and precious metals. The material is difficult to form into special shapes and fractures easily.

- RWMA Class 14, Molybdenum Alloys: These are the most popular electrode metals for welding copper-base and other highly conductive alloys. They minimize the sticking often encountered with copper-alloy electrodes.

Glicop is a dispersion strengthened copper with 0.15% aluminum oxide, 68B Rockwell hardness, 92% conductivity. This material offers longer life, greater thermal stability, and higher strength than RWMA 2. Glidcop is generally interchangeable with RWMA 2 (class 2 copper) without changing schedules. Many customers are switching from Class 2 to Glidcop with good results. We can supply your RWMA electrode materials. Call us today for more details.

| ELECTRODE SELECTION GUIDE | |

| The number which follows each material is the RWMA (Resistance Welder Manufacturers' Association) number of the electrode which would normally be placed against that material. For Example, when welding Alumel to Consil, a RWMA -2 electrode should be used on the Alumel side, and a RWMA -11 on the Consil side. Not all combinations have been tried successfully. | |

| Material | RWMA Electrode Type |

| Alumel | -2 |

| Aluminum | -1 |

| Aluminum Alloys | -1 |

| Beryllium Copper | -2 |

| Brass | -2, -11 |

| Brass, Tinned | -14 |

| Bronze | -2 |

| Cadmium Plating | -1 |

| Chromel | -2 |

| Consil | -11 |

| Constantin | -2 |

| Copel | -2 |

| Copper | -14 |

| Copper, Tinned | -14 |

| Dumet | -2 |

| Dumet, Gold Plated | -2 |

| Evenohm | -14 |

| Gold | -11 |

| Hastalloy | -2 |

| Inconel | -2 |

| Invar | -2 |

| Iridium | -2 |

| Iron | -2 |

| Karma | -2 |

| Kovar | -2 |

| Kovar, Gold Plated | -2 |

| Kulgrid | -2 |

| Magnesium | -1 |

| Manganin | -2 |

| Molybdenum | -2 |

| Nichrome | -2 |

| Nickel | -2 |

| Nickel Alloy | -2 |

| NiSpan C | -2 |

| Nioblum | -2 |

| Paliney 7 | -2 |

| Palladium | -14 |

| Platinum | -2 |

| Rhenium | -2 |

| Silver | -11 |

| Steel, Cold Rolled | -2 |

| Steel, Stainless | -2 |

| Tantalum | -2 |

| Titanium | -2 |

| Tungsten | -2 |

| Zinc | -14 |