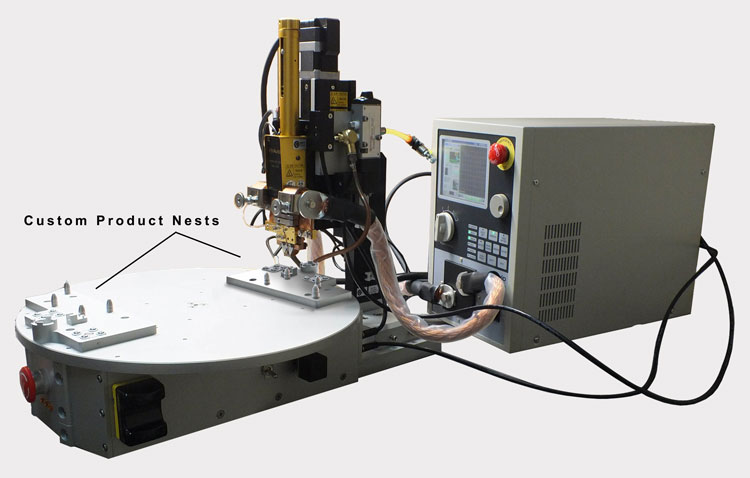

Two-Position Rotary Indexer

Indexer with two product nests that reduces cycle time by 50%

The 2-position indexer can be used with any resistance welding or hot bar soldering system to decrease cycle time by allowing the operator to load and unload products on the front position while the machine is welding/soldering on the back position. This indexer is very simple in design and effective for increasing output. The 2-position rotary indexer is designed with reliability in mind, but it's also designed to make replacing worn parts very simple and quick. Rotary motion is accomplished by use of a stepper motor that drives the rotary table to hard stops at the clockwise and counter-clockwise limits of travel. This is a very cost effective solution for getting more utilization from your welding or hot bar soldering machine.

- High Speed: Indexer takes approximately 1 second to rotate 180 degrees.

- Safe Operation: Utilizes a clutch that makes the rotation safe for operators hands.

- High Reliability: Designed and built for simple and repeatable operation.

Features |

Two-Position Rotary Indexer |

| Cycle Time |

Approximately 1 second |

| System Voltage |

24 Volt |

| Input Voltage Requirement |

110V |

| Size | 16 inch Diameter Table |

| Space Requirement |

24" wide x 42" deep including Avio power supply |