Hot-Bar Soldering Equipment

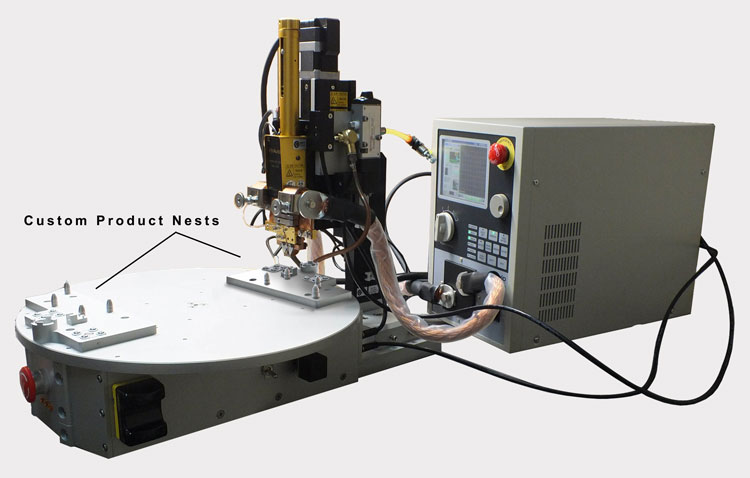

AIT provides the machines and technical support for your Hot-bar Soldering Project.

High quality hot-bar soldering machines

Lower prices on new equipment. Rental equipment available

Shorter lead time on thermodes ( hot bars )

Custom thermodes, tooling, and unparalleled customer support

Advanced Integrated Technologies Inc (AIT) is recognized throughout the world as a leading authority on hot-bar soldering equipment, including the manufacturing of hot-bars and reflow soldering thermodes. Get the benefit of our 20 years of experience building hot-bars (thermodes) for all makes and models of equipment.

Typically the best way to approach the acquisition of a hot-bar system for any application is to send us samples of the products that you wish to bond together. Also we need any information regarding recommended temperature, pressure, and time for the bonding/soldering application. At that point we'll review the requirements and provide pricing and recommendations on how to proceed with the project.

The technology of soldering equipment has come a long way in the last couple of decades. In the early days Hughes Industrial Electronics Group in Carlsbad, California was the pioneer in developing the processes for using an electrically heated metal thermode to reflow presoldered contact pads, forming a bond between electronic components. The original Hughes technology was eventually absorbed into Miyachi Unitek through a series of acquisitions. Miyachi Unitek is still recognized today as one of the largest producers of hot bar bonding and reflow soldering equipment. At AIT we can take your application (samples of your product) and source and engineer a used hot-bar soldering system complete with all tooling required to hold and run your product, at a price far below that of new equipment.

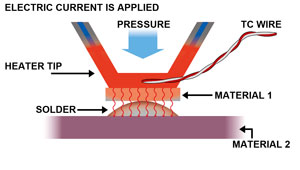

The concept for hot-bar reflow soldering is quite simple. Low voltage, high amperage electricity is run through a metallic thermode that is designed to have higher electrical resistance along the soldering face. The electricity heats the thermode face to a predetermined temperature. Typically most thermodes are fitted with a thermocouple wire that feeds temperature information back to the soldering power supply. The soldering power supply is usually programmable to bring a thermode to a set temperature and hold it for a set amount of time. The thermode is brought into contact with the components to be soldered or bonded, and the heat reflows the solder. Different thermode materials produce different characteristics. Some materials and designs are inherently more dimensionally stable when heated. Others are designed to heat up and cool down quickly. Still others are designed for very even heating along the thermode face.

Nippon Avionics Co.,Ltd, otherwise known as Avio, is a Japanese producer of fine reflow soldering equipment. Avio equipment is widely used in Japan and parts of Asia. Avio reflow heads are designed to look and function very similar to the Hughes/Palomar design. The Avio soldering equipment uses thermodes like our SLD-6 and SLD-18 designs. Most of our product pages for these have a table that cross references the Hot-bar Soldering Equipment manufacturer’s part numbers with AIT equivalent products. Request a quote from us today and discover how AIT can save you money and put our experience to work for you

Outline of Pulse Heat Units

Pulse heat units from Nippon Avionics Co., Ltd. have been used over the years for various applications, including soldering in manufacturing of electronic equipment or electronic components, ACF bonding, plastic welding, and thermo-compression bonding.

In the recent years, improvement of both the function and the performance of mobile devices and other electronic equipment are being accelerated. While the parts are getting smaller and higher in performance, technology to mount parts in high density is becoming very important. Among other things, soldering, which is the key technology in parts manufacturing and assembly, is expected to cope with fine pattern and high reliability.

We are offering suitable micro-joining solutions in a timely manner to satisfy the needs of the customer in the manufacturing industry where technical innovation is remarkable.

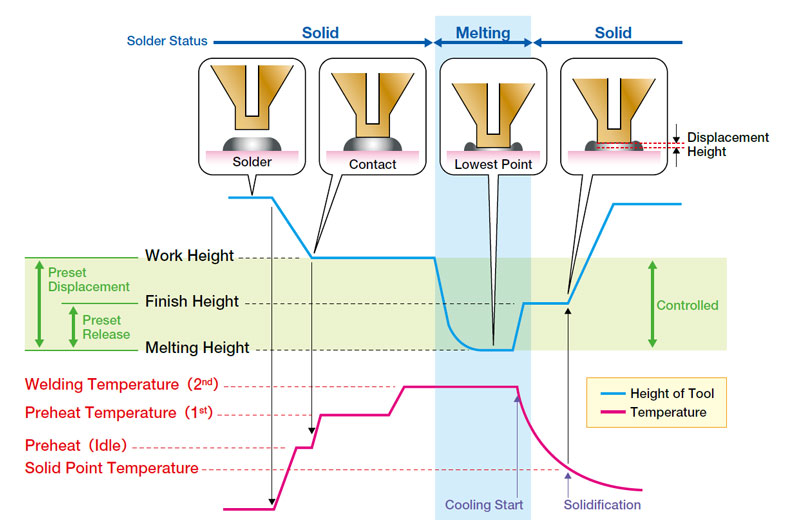

What is Pulse Heat?

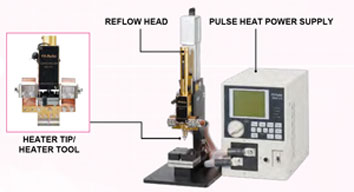

Pulse heat units are equipment used for soldering of electric components or welding of plastic components. It consists of a reflow head, which holds down the component and applies the force, and a pulse heat power supply, which flows the electic current.

Pulse heat is an instantaneous heating method whereby heating is effected only when melting the solder or the plastic. Solder or plastic is melted by the resistance heat generated by flowing electric current to a heater tip/ heater tool made of metal. Once the material is melted, electric current is stopped and cooled.

Because the object is held down with pressure until it is solidified, there is no lifting or shifting of parts, and, as a result, highly reliable joining can be achieved.

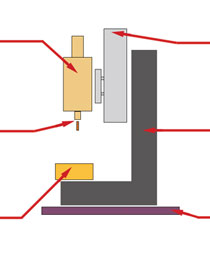

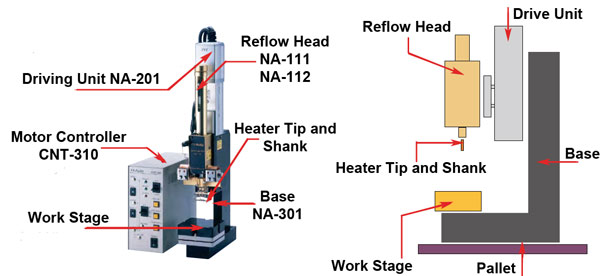

Basic Configuration of a Pulse Heat Unit and Role of Each Part

- Pulse Heat Power Supply: Electric current is flown to the heater tip or heater tool.

- Reflow Head: The object to be joined is held down and force is applied. The applied force is adjusted by a spring.

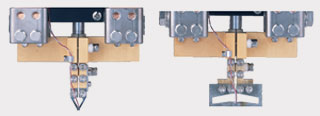

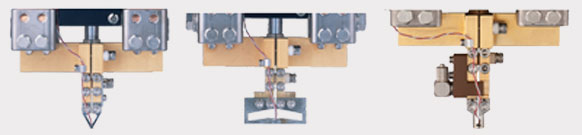

- Heater Tip & Heater Tool: This is the part which becomes hot by resistance heating. The one with a relatively small area is called "heater tip" and a larger area is called "heater tool".

Pulse Heat Unit Model

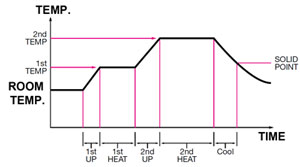

Temperature Profile

| System Head Basic Configuration and Components | |||||

|

|

|

|

|

|

|

|

|

|

||

|

|

|

|

||

Select a power supply with suitable welding capacity depending on the material or the shape of the object to be joined and the required quality level.

Reflow Head

Select a head having a force suitable to the object to be joined and suitable to the heater tip/heater tool to be used.

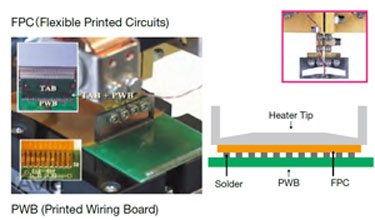

FPC to PWB Reflow Soldering

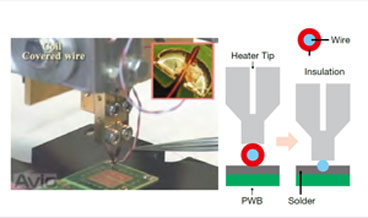

Insulation Wire to PWB Reflow Soldering

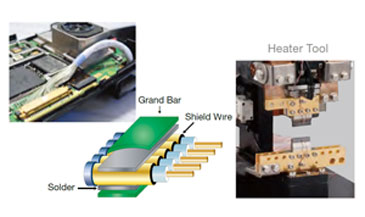

Co-Axial Cable and Grand Bar to Wire Reflow Soldering

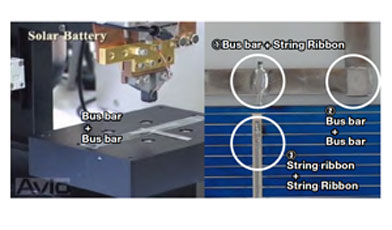

Solar Battery Module Assembly Reflow Soldering

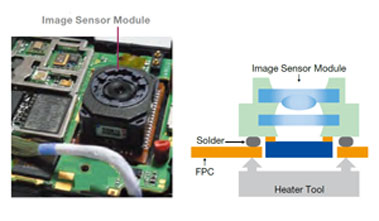

Camera Module Assembly Reflow Soldering

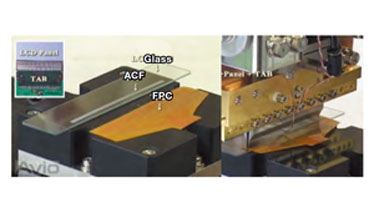

ACF (Glass to FPC)

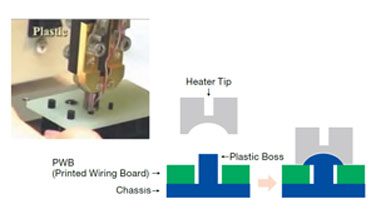

Plastic Parts Fabrication (PWB) Pulse Heat Fusing

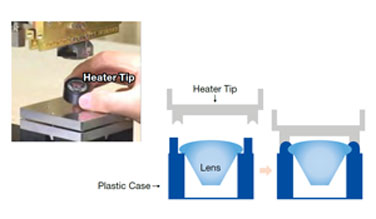

Plastic Parts Fabrication (Lens) Pulse Heat Fusing

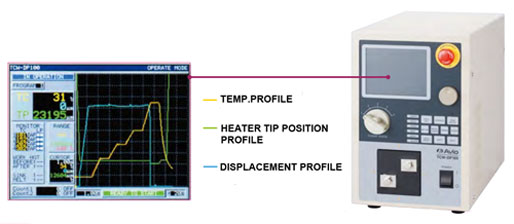

Ultimate Pulse Heat Controller with Concurrency Control of Temperature and Displacement!

Pulse Heat Controller: Concurrency Control of Temperature and Displacement

TCW-DP100

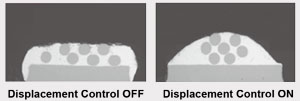

- High Precision Displacement Control: Overtravelling amount is controlled by feedback of displacement amount in 1μm resolution, and uniform melting amount can be realized.

- Wide Variety of Monitoring Functions (Temperature, Displacement)

- Digital Temperature Control: High speed and highly accurate temperature control is realized by the digital PID control method, making the unit suitable for fine wires and micro-miniature works.

- Release Function: After heating, the solder thickness between the works can be secured.

- Four Stage Heating: Various temperature profiles are realized to cope with the diversified applications

- Built-in Motor Control Function

- User Interface: RS-232C&I/O is standard equipped making the unit easy to interface with the external equipment such as the case of incorporating in an automated system.

Melting Amounts Control

Micro Co-axial Cable

- No Spread Wire (Damage Reduction)

- No Solder Bridge

Joining Gap Control

Solar Panel Module

- Enhancement of Joining Strength

- Reduction of Residual Stress

*Reflow head motor drive unitl Model NA-201P is required for use with Model TCW-DP100.*

| Features | TCW-DP100 |

|---|---|

| Heating Temperature |

Room temp~600°C in 1°C step, E type/ J type (option) Room temp~900°C, K type (option) |

| Heating Time | 0.00-99.99 seconds |

| Rated Capacity | 750 VA, 50% duty cycle |

| Heating Steps | 4 Steps |

| Monitor | Sink Amount, Temperature, Work Height |

| Motor Resolution | 1 μm/pulse |

| Displacement Resolution | 1μm |

| Interface | RS-232C, I/O |

| Transformer | Built-In |

| Tap Voltage | 0.88 V, 1.24 V, 1.75 V, 2.47 V, 3.5 V |

| Power Source | AC 200-240 V±10%, 1Φ, 50/60 Hz, 15 A |

| Dimension (mm) | 220x400x320 |

| Weight | 23kg |

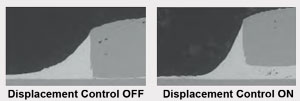

The Best Seller Power Supply Unit Suitable for Soldering, Thermo-Compresion Bonding and Heat-Fusing!

Pulse Heat Power Supply

General Purpose Type

TCW-315

High Power Type

PHU-35

- High Reliability Joining: Becuause heating and cooling take place while the pressure is being applied, the work position will not be shifted during joining.

- Variable Temperature Profile: Because the heating is local and instantaneous, thermal impact to the peripheral components is restrained.

- High Reprodicibility: Digital PID control enables good reproducitbility of temperature and time. As a result, no skill of the operator is required.

- Pb Free Compatible: Pb free solder is accomodated by setting to high temperature and long heating time.

- User Interface: RS-232C&I/O is standard equipped, making the unit easy to be connected to external equipment such as incorporationg into an automated system.

- Ample Monitoring Functions: Temperature Monitoring: Upper and Lower limit (average peak), Profile Detection Error: Over-Heat, Thermocouple Disconnection, etc.

- Other Standard Functions: Number of stored settings: 15, Head vertical and cooling air control signal, Auxiliary thermocouple input, Counter function.

| Features | TCW-315 | PHU-35 | NT-35 |

| Heating Temp. |

Room temp~600°C/1°C step E, J-type Room temp~900°C K-type (Option) |

Room temp~600°C/1°C step E, J-type Room temp~900°C K-type (Option) |

- |

| Heating Time | 000-999(x100ms, x10ms) | 000-999(x100ms, x10ms) | - |

| Rating Power | 750VA | - | 3KVA |

| Transformer | Built-In | - | - |

| Tap Voltage | 0.88 V, 1.24 V, 1.75 V, 2.47 V, 3.5 V | - | 1.0V, 2.0V, 3.0V |

| Power Source | 1Φ, AC200-230V±10%, (AC100-115V: option) | 1Φ, AC200-230V±10%, (AC100-115V: option) | - |

| Dimensions(mm) |

200x320x283 | 278x250x120 | 200x270x220 |

| Weight | 19.5kg | 7.4kg | 25kg |

Temperature Feedback Prevents Cobwebbing of Plastic!

Hand Piece Type

NCU-10U/T/H

Heater Tip for NCU-10H

- Cooling Function: Because the process ends with the plastic solidified, stable fusing without cobwebbing can be achieved.

- Temperature Feedback Function: Temperature variation due to environmental change or passage of time is restrained. Stable Welding by temperature feedback (Plastic sputtering or cracking, as in the case of ultrasonic joining, will not occur)

- Easy to Transport Handy Type

- We can Propose the Most Suitable Heater Tip Based on Our Ample Experience: Heater tip material most suitable to the work material Flat type, multi-point simultaneous heater tip, special coating, etc.

- After Heat Helps Easy Separation of Plastic and the Heater Tip

| Features | NCU-10U | Features | NCU-10T |

| Heat Temperature |

Main: Room temp~499°C Idling: Room temp~299°C |

Rated Power | 150V |

| Heat Time | 0.1-9.9sec(0.1sec/step) | Output Voltage | 1.75V, 2.5V, 3.5V |

| Power Source | AC100V±10% 1Φ (Option:200, 230V) |

Dimensions (mm) | 100x150x120 |

| Compressed Air | 0.4MPA or more | Weight | 3.4kg |

| Dimensions (mm) | 200x302x90 | - | - |

| Weight | 3.5kg | - | - |

High Power Type Suitable for Incorporation into a System!

High Power Type NCU-15/NT-15

- Multi-Heads can be Accomodated: Multi-point simultaneous fusing can be realized

- Compatible to Large Capacity Transformer for Automated System: Compatible to two types, NT-15(1,500VA) and NT-35(3,000VA)

- Pen Type Head Suitable for Automated Systems: Small head (head width 18mm, 21mm, 26.2mm) applicable to narrow pitch with an air cooling port.

| Features | NCU-15 |

|---|---|

| Heat Temperature | Main: Room temp~499°C After-Heat:Room temp~499°C |

| Heat Time | 0.1-9.9sec(0.1sec/step) |

| Power Source | AC200V±10% 1Φ (Option:100, 115, 230V) |

| Compressed Air | - |

| Dimensions(mm) | 200x302x120 |

| Weight | 4.1kg |

| Features | NT-15 | NT-35 |

|---|---|---|

| Rated Power | 1500VA | 3000VA |

| Output Voltage | 1.0V, 2.0V, 3.0V | 1.0V, 2.0V, 3.0V |

| Dimensions (mm) | 160x220x200 | 200x270x220 |

| Weight | 14.2kg | 26kg |

| - | - | - |

| - | - | - |

Multi-Head System

- As the number of head will vary depending on the application, please consult with us

- there will be only one feedback line

- All weld cables have the same length

| Spring Type (300N) |

Spring Type (65N) |

Straight Type |

| Dimensions (mm) | 26.2x101x196.2 | 21x47x192.1 | 18x42x186.9 |

| Weight | 820g | 360g | 160g |

It can be Applied to Various Types of Equipment!

ACF Thermo-Compression Bonder

TCW-125C

- Semi-Automatic Equipment Accommodating the Heater Tool: It can be used for wide range of applications covering from thermo-compression bonding of ACF or heat seal of LCD to soldering.

- CCD Camera and LCD Monitor can be Connected as Options: Work can be postponed while monitoring the image from the CCD camera.

| Features | TCW-125C |

| Power Supply | PHU-35 |

| Tap Voltage | 1.0V, 2.0V, 3.0V |

| Heater Tool Length | 110mm Max |

| Pressure | 68.6~833N |

| Weight | 180kg |

|

*We can Propose an Automated System SatisfyingYour Requirement. Please Feel Free to Consult with Us* |

| Examples of Equipment Using Pulse Heat Unit |

|

Best Suitable for a Precise Joining and Automation!

Heater Tip Type

NA-111, NA-112

| Features | NA-111 | |

| Pressure Range | 0.7-5N | |

| Pressure Method | Spring | |

| Stroke | It's up to Drive Unit | |

| Dimensions (mm) | 106x48x287 | |

| Weight | 0.6kg | |

| Drive Method | Motor(NA-201), Air(NA-221), Manual(NA-231) | |

| Features | NA-112 | |

| Pressure Range | 5-65N | |

| Pressure Method | Spring | |

| Stroke | It's up to Drive Unit | |

| Dimensions (mm) | 106x48x285 | |

| Weight | 0.6kg | |

| Drive Method | Motor(NA-201), Air(NA-221), Manual(NA-231) | |

- Because of the Vertical Direct Force Application Mechanism There is No Deflection by the Applied Force

- Long Life is Realized by the Use of a Photo Sensor

Heater Tool Type

NA-151, NA-152, NA-153

| Features | NA-151 | NA-152 | NA-153 | ||

| Pressure Range | 1.2-7N | 5-70N | 20-150N | ||

| Pressure Method | Spring | ||||

| Stroke | It's up to Drive Unit | ||||

| Dimensions (mm) | 124x54.8x298 | ||||

| Weight | 1kg | ||||

| Drive Method | Motor(NA-201), Air(NA-221), Manual(NA-231) | ||||

NA-154

| Features | NA-154 | ||||

| Pressure Range | 40-300N | ||||

| Pressure Method | Spring | ||||

| Stroke | It's up to Drive Unit | ||||

| Dimensions (mm) | 145x64.5x332 | ||||

| Weight | 2.2kg | ||||

| Drive Method | Air(NA-222) | ||||

NA-155

| Features | NA-155 | ||||

| Pressure Range | 100-600N | ||||

| Pressure Method | Spring | ||||

| Stroke | 30mm | ||||

| Dimensions (mm) | 217x230x700 | ||||

| Weight | 20.1kg | ||||

| Drive Method | Air | ||||

Heater Tool and Shank

- Provided with Air Cooling Port and Flatness Adjustment Function

- Water Cooled Shank is Equipped as Standard (NA-154, NA-166)

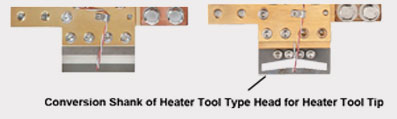

- Heater Tip can be Used by Use of a Conversion Shank

- It's equiped with a soft landing and teaching function.

- 5 operating speeds.

- Operation position can be set by 4 points.

- Timing of weld confirmed by LED

NA-201

CNT-310

NA-201+CNT-310

| Features | NA-201+CNT-310 |

| Dimensions NA-201 (mm) | 50x82.5x320 |

| Dimensions CNT-310 (mm) | 80x211x188 |

| Weight | NA-201: 2kg; CNT-310: 2kg |

| Drive Method | Pulse Motor |

| Stroke | 50mm Max, 10 μm Step |

| Power Source |

DC 24V±10% 2A, Optional: AC Adaptor AC100-240V |

Air Drive

NA-221,222

| Features | NA-221 | NA-222 |

| Dimensions (mm) | 78x63x280 | 86x85x289 |

| Weight | 1.3 kg | 2.2 kg |

| Drive Method | Air | Air |

| Stroke | 50mm Max | 50mm Max |

| Speed Control | with speed controller - (Φ4mm tube) | with speed controller - (Φ6mm tube) |

| Air Pressure | 0.05-0.6MPa | 0.4-0.6MPa |

Manual Drive

NA-231

| Features | NA-231 |

| Dimensions (mm) | Drive Part: 51x79x192; Foot Pedal: 124x268x125 |

| Weight | Drive Part: 1kg; Foot Pedal: 2.2kg |

| Drive Method | Manual by Foot Pedal |

| Stroke | 10mm Max |

| Height Control | 40 mm Range |

Displacement is Realized!

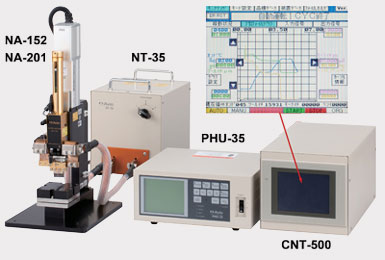

Displacement Unit

CNT-500

- Connectable to TCW-315, PHU-35 and NCU-15

- Easy Operation by Touch Panel Control

- Control of Crushed Amount by Displacement

- Because of the Heat Shift Function, Thermal Impact to the Work is Minimized

Temperature and Displacement

| Features | CNT-500 |

| Display | Touch Panel |

| Motor Resolution | 6.25 μm/pulse (NA-201) |

| Displacement Setting Resolution | 1 μm/scale (0-8192 μm range) |

| Use-srounding Temperature | 0°C-40°C (without freezing) |

| Use-srounding Humidity | 85% or less (without condensation) |

| Power Source | AC100V-240V |

| Consumption Power | 50W or less |

| Dimensions (mm) | 200x360x190 |

| Weight | 6.5kg |

System Head Basic Configuration

Base

NA-301, 302

Pallet

S-MP, 5302-MP

Microscope Set

Microsocope, Mounting Stand, LED, and Pallet

S-SMS, S-SMS-MS, S-SMS-LED

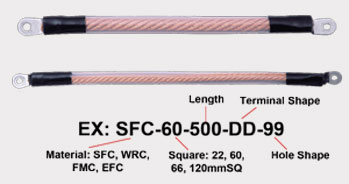

Weld Cable

Cable

Stages

Stage

1X-BS

Leveling Stage

11X-BS-F

XYZ Stage

11X-BS-F-MM

Heater Stage

11X-BS-H

Standard Type

NA-62D

| Features | NA-62D |

| Pressure Range | 4.9-44.1N |

| Stroke | 8mm |

| Dimensions (mm) | 77x212x275 |

| Weight | 2.4kg |

| Driving Method | Manual by Foot Pedal |

Air Drive Type

NA-66

| Features | NA-66 |

| Pressure Range | 4.9-44.1N |

| Stroke | 8mm |

| Dimensions (mm) | 77x212x360 |

| Weight | 3.8kg |

| Driving Method | Air |

- Monolithic Head with Integrated Drive Section and Force Application Section

- Heater Tips are Accommodated

- Two Types: Manual Driven and Air Driven

NA-62D, NA-66 Microscope Stand

- Magnification: 8x-50x

- Dimensions (mm): W550xD800xH20

- Height: 434mm

Compact, Light Weight, and Handy Type

- Compact and Light Weight

- 3 Way Power Supply

- Equipped with Hold Display Function

- Easy Zero Adjustment Function

- Equipped with Judgment Function (Hi&Low)

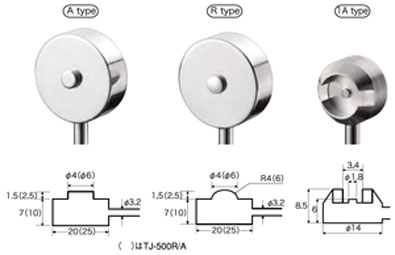

FG-400 & TJ series

| Features |

FG-400 |

| Display | 4 digit (0000-9999) N: newton |

| Zeroing Adjustment | Automatic Regulation by Switching |

| Hold Function | Sample/Peak |

| Interface | RS-232C |

| Power Source | (AC100V-240V)1Φ Use by AA type battery, Ni-H type battery or Dedicated AC adapter (AC100V-240V) |

| Dimension (mm) | 77x140x27 |

| Weight | 300g |

| Features |

TJ-1A |

TJ-20R or TJ-20A |

TJ-100R or TJ-100A |

TJ-500R or TJ-500A |

| Measuring Range (N) | 0-10 | 0-196 | 0-980 | 0-4900 |

| Critical Load (N) | 20 | 294 | 1470 | 7350 |

| Accuracy | ±2% (of full scale) | |||

Sensor Tip Shape

Pressure Sensor |

||||

| Features | TJS-1R | TJS-20R | TJS-100R |  |

| Measuring Range (N) | 0-10 | 0-196 | 0-980 | |

| Critical Load (N) | 20 | 294 | 1470 | |

| Accuracy | ±3% (of full scale) | |||

Real Time Monitoring of Displacement and Force

- Digital or Graphic Display Options

- Easy Automation When Combined with System Head

- Easy QC by Enhanced Communication Function (Output of Measured Value m& Monitoring Result)

- Easy Installation of Force Sensor

- High Accuracy for Displacement Bonding

- Wave Analysis by Graphic Display (High Speed Sampling at 2000 times/sec)

- Measure and Judge by 2 Conditions for Bonding

- Trigger by Applied Force or Displacement Setting

Force Monitor

QC-100

| Features | QC-100 | |

| Measurement Range | 0-1000N | |

| Accuracy | ±3%(of full scale) | |

| Sampling Time | 0.5ms(2000 times/sec) | |

| Squeeze, Hold Time | 0-0.9sec | |

| Interface | RS-232C, I/O, analog output | |

| Power Source | DC24V ± 10% 2A | |

| Dimension (mm) | 170x210x150 | |

| Weight | 3kg | |

Displacement Monitor

QC-200

| Features | QC-200 | |

| Measurement Range | 0-7.5mm Resolution: 1μm | |

| Accuracy | ±1%(of full scale) | |

| Sampling Time | 0.5ms(2000 times/sec) | |

| Squeeze, Hold Time | 0-0.9sec | |

| Interface | RS-232C, I/O, analog output | |

| Power Source | DC24V ± 10% 2A | |

| Dimension (mm) | 170x210x150 | |

| Weight | 3.4kg | |

| Features | TJS-1R | TJS-20R | TJS-100R |

|

| Measurement Range (N) | 0-10 | 0-196 | 0-980 | |

| Critical Load (N) | 20 | 294 | 1470 | |

| Accuracy | ±3%(of full scale) | |||

Real Time Monitoring of Displacement and Force

- Digital or Graphic Display Options

- Easy Automation When Combined with System Head

- Easy QC by Enhanced Communication Function (Output of Measured Value m& Monitoring Result)

- Easy Installation of Force Sensor

- High Accuracy for Displacement Bonding

- Wave Analysis by Graphic Display (High Speed Sampling at 2000 times/sec)

- Measure and Judge by 2 Conditions for Bonding

- Trigger by Applied Force or Displacement Setting

Force Monitor

QC-100

| Features | QC-100 | |

| Measurement Range | 0-1000N | |

| Accuracy | ±3%(of full scale) | |

| Sampling Time | 0.5ms(2000 times/sec) | |

| Squeeze, Hold Time | 0-0.9sec | |

| Interface | RS-232C, I/O, analog output | |

| Power Source | DC24V ± 10% 2A | |

| Dimension (mm) | 170x210x150 | |

| Weight | 3kg | |

Displacement Monitor

QC-200

| Features | QC-200 | |

| Measurement Range | 0-7.5mm Resolution: 1μm | |

| Accuracy | ±1%(of full scale) | |

| Sampling Time | 0.5ms(2000 times/sec) | |

| Squeeze, Hold Time | 0-0.9sec | |

| Interface | RS-232C, I/O, analog output | |

| Power Source | DC24V ± 10% 2A | |

| Dimension (mm) | 170x210x150 | |

| Weight | 3.4kg | |

| Features | TJS-1R | TJS-20R | TJS-100R |

|

| Measurement Range (N) | 0-10 | 0-196 | 0-980 | |

| Critical Load (N) | 20 | 294 | 1470 | |

| Accuracy | ±3%(of full scale) | |||