Inverter Spot Welder

AIT offers the AVIO line of quality high speed Inverter Welders

At Advanced Integrated Technologies (AIT), we specialize in providing the best equipment and technical support for your welding needs. As a provider of Nippon Avionics (Avio) brand of precision inverter spot welders, we offer free test welds to help determine if our equipment is suitable for your application.

Providing you with equipment and technical support

Lower prices on equipment and electrodes than other manufacturers

Shorter lead time, especially on electrodes

Free test weldsand unparalleled customer support

How We Can Help You

We have chosen the AVIO line of equipment because it offers advanced technology, precision, and quality at a reasonable price compared to other popular brands. Our inverter spot welders utilize pulse width modulation to control weld energy, resulting in DC current with low-level AC ripple. With high repetition rates, inverter welders are useful in industrial automation and are built such that they can be wires into automated systems and controlled by a plc if needed.

Click here for matching weld heads.AVIO Inverter Welders

- High speed and precise control of wave form

- 3 Feedback modes (constant current, voltage, or power)

- Pre-weld check function

- Up to 3 second weld time

- LCD graphic display of welding wave form

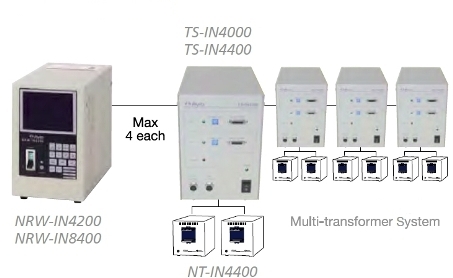

- Multi Transformer System

Multi-transformer System

Graphic Display of Welding Waveform

| Features | NRW-IN4200 | NRW-IN8400 |

| Welding Transformer | NT-IN4400 | NT-IN8400 / NT-IN4400 |

| Maximum Current | 4000A | 8000A / 4000A |

| Control Frequency | 2KHz | |

| Control Mode | Constant Current, Voltage, or Power. Fixed Pulse Width | |

| Range of Timer Setting | Pre, 1st, 2nd, UP, WELD, DOWN | |

| Total Time 0.5 - 3000ms | ||

| Setting Range for Weld Type | Current 0.4 - 4.1KA | Current 0.4 - 8.2kA / 0.4 - 4.1kA |

| Voltage 0.4 - 4.1V | Voltage 0.4 - 6.2V / 0.4 - 4.1V | |

| Power 0.2 - 8.2kW | Power 0.2 - 24.5kW / 0.2 - 8.2kW | |

| Current/Voltage/Power, Resistance Monitoring | Average/Peak/Profile | |

| Trace Monitoring | Current, Voltage, Power, Resistance | |

| Display of Wave Form | Current, Voltage, Power, Resistance | |

| Number of Condition | 31 | |

| Interface | RS232C | |

| Power Source | 200-230 V AC | 380-415V AC / Optional 200-230 V AC |

We can assist you with any technical issues you encounter during the setup of your welding process, and we manufacture all electrodes in our facility in the United States. We can even build custom electrodes to help resolve any welding issues you encounter.

Closed loop welders like inverter type (high-frequency inverter) and transistor type (linear DC) welders can control the welding waveform's shape and monitor the weld's condition using feedback modes like "constant current," "constant voltage," or "constant power." These modes offer advantages such as better process consistency, reduced weld failures, and automatic adjustment for variations in part thermal loading and plating. Our Avio inverter spot welders are premium quality Japanese-made high-frequency inverter welders that utilize these feedback modes to provide superior welding results.

Contact us today by filling out our contact form or giving us a call to request assistance with your next project. Let AIT show you how our spot welders and expertise can make your next welding project a success.