AIT S-16 Resistance Welding Electrode

S-16 Round Version

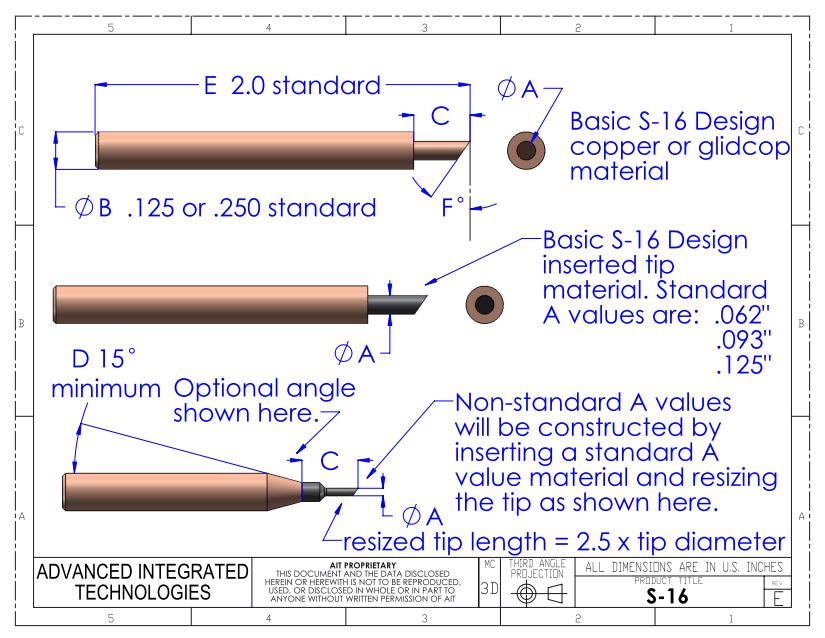

The S-16 series is a round electrode with the central feature being an angled tip. See the drawing for an understanding of the various dimensional values and construction of this electrode. It comes with a .125” or .250” diameter copper body. Glidcop and copper versions are built from one piece, and essentially any A value larger than .025” diameter is acceptable in these two materials. Tip materials of class 11 copper-tungsten, class 13 pure tungsten (W), and molybdenum (M) have the tip pressed into the shank, with standard A values for pressed materials being .062” , .093” , and .125” . Other A values requested in pressed materials will be constructed by inserting a standard A diameter material size, and then resizing the end of the tip. This electrode also has an optional clearance angle “D” that can be added to the electrode if needed. Leave the D value completely out of the part number if you do not need this clearance angle. Please note that requesting a D angle, as well as using non-standard A dimensions with class 11, class 13, and molybdenum materials will add additional cost to the base price of the electrode. Adding a –B to the end of the part number makes the tip brazed into the copper shank. Adding a -P to the end of the part number makes the tip pressed into the copper shank with no brazing. While brazing the tip material into the shank adds some additional cost to the electrode, we highly recommend using this option, as it produces a superior electrode. An electrode with a pressed tip and no brazing has the potential for the resistance to change due to oxidation of materials at the joint between the tip and shank. This can lead to inconsistent welding results. Custom materials are also available. Contact the factory for assistance at (870)-269-4367.

The S-16 series is a round electrode with the central feature being an angled tip. See the drawing for an understanding of the various dimensional values and construction of this electrode. It comes with a .125” or .250” diameter copper body. Glidcop and copper versions are built from one piece, and essentially any A value larger than .025” diameter is acceptable in these two materials. Tip materials of class 11 copper-tungsten, class 13 pure tungsten (W), and molybdenum (M) have the tip pressed into the shank, with standard A values for pressed materials being .062” , .093” , and .125” . Other A values requested in pressed materials will be constructed by inserting a standard A diameter material size, and then resizing the end of the tip. This electrode also has an optional clearance angle “D” that can be added to the electrode if needed. Leave the D value completely out of the part number if you do not need this clearance angle. Please note that requesting a D angle, as well as using non-standard A dimensions with class 11, class 13, and molybdenum materials will add additional cost to the base price of the electrode. Adding a –B to the end of the part number makes the tip brazed into the copper shank. Adding a -P to the end of the part number makes the tip pressed into the copper shank with no brazing. While brazing the tip material into the shank adds some additional cost to the electrode, we highly recommend using this option, as it produces a superior electrode. An electrode with a pressed tip and no brazing has the potential for the resistance to change due to oxidation of materials at the joint between the tip and shank. This can lead to inconsistent welding results. Custom materials are also available. Contact the factory for assistance at (870)-269-4367.

S-16 square version

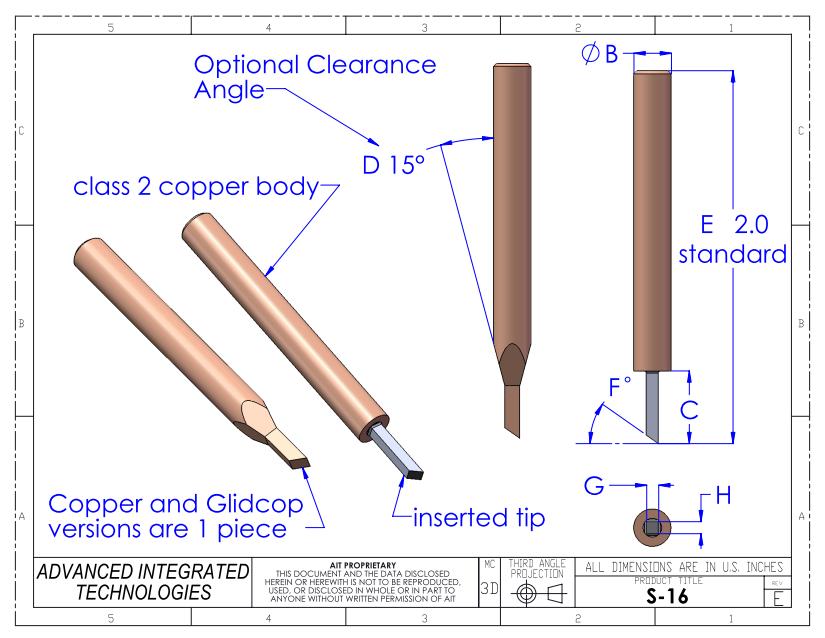

The S-16 electrode can be requested with a square tip. Please see the drawing for details. It comes with a .125” or .250” diameter copper body. Glidcop and copper versions are built from one piece. Tip materials of class 11 copper-tungsten, class 13 pure tungsten, and molybdenum have the tip pressed into the shank. Tip lengths should not exceed 2.5 times the G or H dimensions, whichever is smaller. This electrode also has an optional clearance angle “D” that can be added to the electrode if needed. Leave the D value completely out of the part number if you do not need this clearance angle. Please note that requesting a D angle will add additional cost to the base price of the electrode. Adding a –B to the end of the part number makes the tip brazed into the copper shank. Adding a -P to the end of the part number makes the tip pressed into the copper shank with no brazing. While brazing the tip material into the shank adds some additional cost to the electrode, we highly recommend using this option, as it produces a superior electrode. An electrode with a pressed tip and no brazing has the potential for the resistance to change due to oxidation of materials at the joint between the tip and shank. This can lead to inconsistent welding results. Custom materials are also available. Contact the factory for assistance at (870)-269-4367.

The S-16 electrode can be requested with a square tip. Please see the drawing for details. It comes with a .125” or .250” diameter copper body. Glidcop and copper versions are built from one piece. Tip materials of class 11 copper-tungsten, class 13 pure tungsten, and molybdenum have the tip pressed into the shank. Tip lengths should not exceed 2.5 times the G or H dimensions, whichever is smaller. This electrode also has an optional clearance angle “D” that can be added to the electrode if needed. Leave the D value completely out of the part number if you do not need this clearance angle. Please note that requesting a D angle will add additional cost to the base price of the electrode. Adding a –B to the end of the part number makes the tip brazed into the copper shank. Adding a -P to the end of the part number makes the tip pressed into the copper shank with no brazing. While brazing the tip material into the shank adds some additional cost to the electrode, we highly recommend using this option, as it produces a superior electrode. An electrode with a pressed tip and no brazing has the potential for the resistance to change due to oxidation of materials at the joint between the tip and shank. This can lead to inconsistent welding results. Custom materials are also available. Contact the factory for assistance at (870)-269-4367.