Resistance Welding Equipment

PROVIDING YOU WITH FINE RESISTANCE SPOT WELDING EQUIPMENT, RENTALS, ELECTRODES, AND SUPPORT FOR YOUR SPOT WELDING PROJECT.

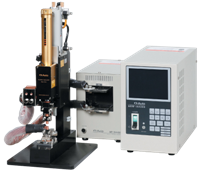

Advanced Integrated Technologies ( AIT ) is a resistance welding equipment and technical support provider for Nippon Avionics ( Avio ) brand of resistance spot welders and accessories as well as Sunstone brand spot welders. We can evaluate your product samples, provide free test welds, and accurately specify which equipment is best for your application. We can then provide the equipment you need at an economical price, and assist with any technical issues you encounter setting up your welding process. Submit a contact form or call us today to request assistance with your next project.

High precision resistance welders and electrodes

Lower prices on equipment and electrodes than other manufacturers

Shorter lead time on electrodes

Custom welding solutions and unparalleled customer support

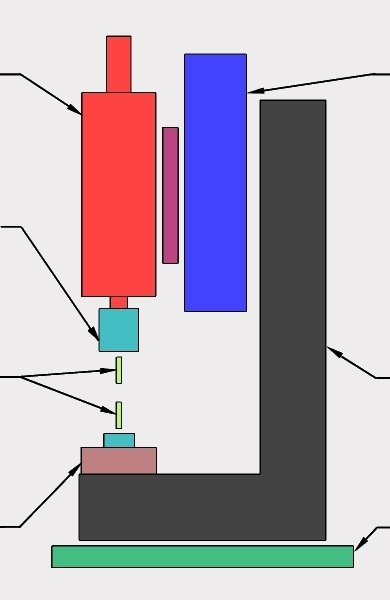

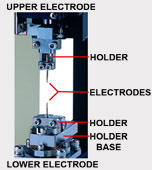

Opposed Gap Spot Welding

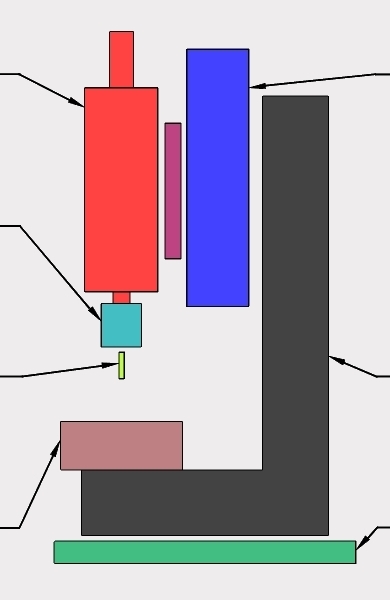

Parallel Gap Spot Welding

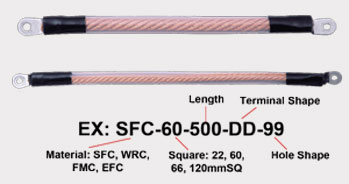

With an inverter type welder, AC input current is rectified into DC output current. Because of the high frequency and good heat efficiency, this type of welder is suitable for precision welding of electronics components. The inverter welder offers three control modes: constant voltage, constant current, or constant power. The voltage feedback function allows the welder to adjust to changes in the weld condition in real time, leading to stable, quality welds. High speed repetitive welding makes this welder good for automated systems.

With a linear DC welder, the electric current is directly controlled by a transistor. This produces fast control speed and a controlled wave form. With a high speed linear controller, this welder is suitable for welding of very small components or extremely fine wires. The transistor welder offers three control modes: constant voltage, constant current, or constant power. The control modes make possible very dependable and consistent welds.

The hybrid type battery spot welder possesses the high speed properties of a DC power supply, and the polarity switching function of an AC power supply. The polarity of a high current is switched at high speed by a power transistor. This type of welder is very good for battery tab welding, where different types of metals must be series welded.

With a capacitor discharge welder, electric energy is stored in a capacitor and discharged all at once. Because a large current can be discharged all at once, this type is useful for welding highly conductive materials such as aluminum and copper. Also because of the short welding duration, heat impact on surrounding material is minimized, making it useful for welding small sensitive components.

In a single phase AC welder, current is controlled by a thyrister, and operates at relatively low peak current. This type of weld current is less affected by dirt or contamination at the weld. Because the weld time can be adjusted more wide range, this type of welder is suitable for thick plates and copper wire.

| Features | Opposed Type |

| NA-121 | |

| Pressure Range (N) | 0.7 - 5 |

| Dimension (mm) | 74x48x285 |

| Weight (kg) | 0.6 |

| Drive Method | motor, air, manual |

| Features | Opposed Type |

| NA-122 | |

| Pressure Range (N) | 6 - 65 |

| Dimension (mm) | 82x50x301 |

| Weight (kg) | 0.8 |

| Drive Method | motor, air, manual |

| Features | Opposed Type |

| NA-123 | |

| Pressure Range (N) | 20 - 150 |

| Dimension (mm) | 82x50x301 |

| Weight (kg) | 0.8 |

| Drive Method | motor, air, manual |

| Features | Opposed Type |

| NA-124 | |

| Pressure Range (N) | 40 - 300 |

| Dimension (mm) | 98x56x326 |

| Weight (kg) | 1.5 |

| Drive Method | air |

| Features | Opposed Type |

| NA-125 | |

| Pressure Range (N) | 100 - 600 |

| Dimension (mm) | 212x204x75 |

| Weight (kg) | 21.5 |

| Drive Method | EH-F-02 Shown |

NA-131

| Parallel Gap Type | ||

| Features | NA-131 | |

| Pressure Range (N) | 0.7 - 5 | |

| Dimension (mm) | 76x51x299 | |

| Weight (kg) | 0.7 | |

| Drive Method | motor,air, manual | |

NA-132

| Parallel Gap Type | ||

| Features | NA-132 | |

| Pressure Range (N) | 5 - 65 | |

| Dimension (mm) | 76x51x299 | |

| Weight (kg) | 0.7 | |

| Drive Method | motor,air, manual | |

NA-142

| Series Type | |||

| Features | NA-141 | NA-142 | |

| Pressure Range (N) | 0.5 - 5 | 5 - 65 | |

| Dimension (mm) | 136x50x268 | 153x50x268 | |

| Weight (kg) | 1.3 | 1.6 | |

| Drive Method | motor,air, manual | motor,air, manual | |

NA-143

| Series Type | |||

| Features | NA-143 | ||

| Pressure Range (N) | 40 - 150 | ||

| Dimension (mm) | 175x62x302 | ||

| Weight (kg) | 2.7 | ||

| Drive Method | motor,air, manual | ||

NA-60A

The NA-60A is a general purpose weld head with wide applications for many kinds of electrical parts that require accuracy and reliability, such as switches, relay contacts, watches, camera components, and other various mechanical parts.

General Purpose Type

| Features | NA-60A |

| Pressure Range (N) | 9.8-132.3 |

| Dimension (mm) | 72x175x285 |

| Weight (kg) | 2.8 |

| Driving Method | foot, air |

| Electrode Diameter (mm) | 6.4/3.2 |

| Pocket Depth Dimension | 98mm |

| Electrode Stroke | 12mm Max |

NA-72

The NA-72 is suited for the welding of various mechanical parts or thick-stranded wires that need a stronger electrode force.

High Pressurization Type

| Features | NA-72 |

| Pressure Range (N) | 98-588 |

| Dimension (mm) | 107x240x615 |

| Weight (kg) | 19 |

| Driving Method | air |

| Electrode Diameter (mm) | 10 |

| Pocket Depth Dimension | 160mm |

| Electrode Stroke | 30mm Max |

NA-43

The NA-43 is used for automated machines due to the use of a floating system that rarely produces dislocation, as well as a standard air drive unit.

Horizontal Pressure Type

| Features | NA-43 |

| Pressure Range (N) | 88.2-294 |

| Dimension (mm) | 248x240x319 |

| Weight (kg) | 11 |

| Driving Method | air |

| Electrode Diameter (mm) | 6.4 |

| Pocket Depth Dimension | - |

| Electrode Stroke | 12mm Max |

- It's equiped with a soft landing and teaching function.

- 5 operating speeds.

- Operation position can be set by 4 points.

- Timing of weld confirmed by LED

NA-201

CNT-310

NA-201+CNT-310

| Features | NA-201+CNT-310 |

| Dimensions NA-201 (mm) | 50x82.5x320 |

| Dimensions CNT-310 (mm) | 80x211x188 |

| Weight | NA-201: 2kg; CNT-310: 2kg |

| Drive Method | Pulse Motor |

| Stroke | 50mm Max, 10 μm Step |

| Power Source |

DC 24V±10% 2A, Optional: AC Adaptor AC100-240V |

Air Drive

NA-221,222

| Features | NA-221 | NA-222 |

| Dimensions (mm) | 78x63x280 | 86x85x289 |

| Weight | 1.3 kg | 2.2 kg |

| Drive Method | Air | Air |

| Stroke | 50mm Max | 50mm Max |

| Speed Control | with speed controller - (Φ4mm tube) | with speed controller - (Φ6mm tube) |

| Air Pressure | 0.05-0.6MPa | 0.4-0.6MPa |

Manual Drive

NA-231

| Features | NA-231 |

| Dimensions (mm) | Drive Part: 51x79x192; Foot Pedal: 124x268x125 |

| Weight | Drive Part: 1kg; Foot Pedal: 2.2kg |

| Drive Method | Manual by Foot Pedal |

| Stroke | 10mm Max |

| Height Control | 40 mm Range |

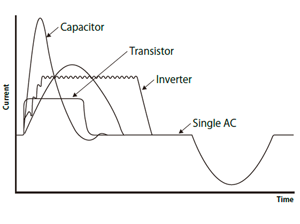

Straight Type

Shift Type

Upper Electrode Accessory |

||||

| Head | Electrode Clamping Diameter | Type | Holder/Horn | Clamp |

| NA-121 |

.0625" / 1.6mm | Straight | S121-16THD | - |

| Shift | S121-16HORN | S121-CLMP | ||

| .125" / 3.2mm | Straight | S121-32THD | - | |

| Shift | S121-32HORN | S121-CLMP | ||

| NA-122 |

.125" / 3.2mm | Straight | S122-32THD | - |

| Shift | S122-32HORN | S122-CLMP | ||

| .250" / 6.4mm | Straight | S122-64THD | - | |

| Shift | S122-64HORN | S122-CLMP | ||

| NA-124 |

.250" / 6.4mm | Straight | S124-64THD | - |

| 8mm | Straight | S124-80THD | - | |

| Lower Electrode Accessory | ||||

| Head | ;Electrode Clamping Diameter | Type | Holder/Horn | Holder Base/Clamp |

| NA-121 | .0625" / 1.6mm | Straight | S12X-16BHD | 12X-B-F |

| Shift | S12X-16BHORN | 12X- BS | ||

| .125" / 3.2mm | Straight | S12X-32BHD | 12X-B-F | |

| Shift | S12X-32BHORN | 12X-BS | ||

| NA-122 | .125" / 3.2mm | Straight | S12X-32BHD | 12X-B-F |

| Shift | S12X-32BHORN | 12X-BS | ||

| .250" / 6.4mm | Straight | S12X-64BHD | 12X-B-F | |

| Shift | S12X-64BHORN | 12X-BS | ||

| NA-124 | .250" / 6.4mm | Straight | S12X-64BHD | 124-B-F |

| 8mm | Straight | S12X-80BHD | 124-B-F | |

| Lower Holder Accessory |

| Lower Holder & Lower Holder Base |

| S12X-16BHD & 12X-B-F |

|

Lower Electrode Stage

143-BS

.jpg)

Stage

11X-BS

Leveling Stage

11X-BS-F

XYZ Stage

11X-BS-F-MM

Base

NA-301, 302

Pallet

S-MP

Microscope Set

Microsocope, Mounting Stand, LED, and Pallet

S302-MP, S-SMS, S-SMS-MS, S-SMS-LED

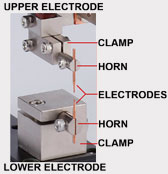

Weld Cable

Cable

The welding machine series of hand operated models are arranged to weld a difficult object that can't be welded by a fixed type weld head, like at a jamming area. No side-to-side rocking of electrodes. Operating with low power due to their compact and lightweight size.

NA-54A

| Features | NA-54A |

| Pressure Range (N) | 7.8-44.1 |

| Electrode Stroke | 10mm Max |

| Depth Dimension of Pocket | 50mm |

| Driving Method | Manual |

| Applicable Electrode | EL-125 Series |

| Dimensions (mm) | 30x195x47 |

| Weld Cable | 1500mm |

NA-54LA

| Features | NA-54LA |

| Pressure Range (N) | 7.8-44.1 |

| Electrode Stroke | - |

| Depth Dimension of Pocket | - |

| Driving Method | Manual |

| Applicable Electrode | EL-54L |

| Dimensions (mm) | 30x195x47 |

| Weld Cable | 1500mm |

NA-57A

| Features | NA-57A |

| Pressure Range (N) | 9.8-49 |

| Electrode Stroke | - |

| Depth Dimension of Pocket | - |

| Driving Method | Manual |

| Applicable Electrode | Specialized for NA-57A |

| Dimensions (mm) | 36Φ xD207mm |

| Weld Cable | 1500mm |

NA-58A

| Features | NA-58A |

| Pressure Range (N) | Manual |

| Electrode Stroke | 1mm Max |

| Depth Dimension of Pocket | 75mm |

| Driving Method | Manual |

| Applicable Electrode | Specialized for NA-58A |

| Dimensions (mm) | 24x16x157 |

| Weld Cable | 1100mm |

High Reliability for QC

- Digital or Graphic Display Options

- Easy Automation When Combined with System Head

- Easy QC by Enhanced Communication Function (Output of Measured Value m& Monitoring Result)

- Easy Installation of Force Sensor

- High Accuracy for Displacement Welding

- Wave Analysis by Graphic Display (High Speed Sampling at 2000 times/sec)

- Measure and Judge by 2 Conditions for Welding

- Trigger by Applied Force or Displacement Setting

Force Monitor

QC-100

| Features | QC-100 | |

| Measurement Range | 0-1000N | |

| Accuracy | ±3%(of full scale) | |

| Sampling Time | 0.5ms(2000 times/sec) | |

| Squeeze, Hold Time | 0-0.9sec | |

| Interface | RS-232C, I/O, analog output | |

| Power Source | DC24V ± 10% 2A | |

| Dimension (mm) | 170x210x150 | |

| Weight | 3kg | |

Displacement Monitor

QC-200

| Features | QC-200 | |

| Measurement Range | 0-7.5mm Resolution: 1μm | |

| Accuracy | ±1%(of full scale) | |

| Sampling Time | 0.5ms(2000 times/sec) | |

| Squeeze, Hold Time | 0-0.9sec | |

| Interface | RS-232C, I/O, analog output | |

| Power Source | DC24V ± 10% 2A | |

| Dimension (mm) | 170x210x150 | |

| Weight | 3.4kg | |

| Features | TJS-1R | TJS-20R | TJS-100R |

|

| Measurement Range (N) | 0-10 | 0-196 | 0-980 | |

| Critical Load (N) | 20 | 294 | 1470 | |

| Accuracy | ±3%(of full scale) | |||

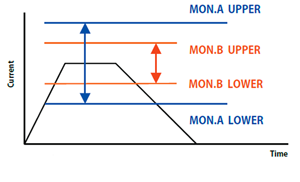

Monitoring of Welding Current

Welding Monitor QC-440

Welding Wave Form

Toroidal-Coil

Setting Example

| Features | Specifications |

| Type | QC-440 |

| Wave Form | Single AC Type, Capacitor Type, Inverter Type, Transistor Type |

| Current | 0.50-45.0KA |

| Time | 0.5-99.5cycle (0.5cycle step) 1-199msec (capacitor mode 1ms Step) |

| Displacement | Measurement Range -99.99-99.99mm or -9.999-9.999mm |

| Accuracy | Current±2% (F.S) Time±0% |

| Judgment Items |

Current: over, under (3digits) Time: over, under (Cycle: 2digits msec: 3digits) Displacement: over, under (4digits) *With GOOD or NG Signal Output Function |

| Display Items | Chanel, Current Value(A/B), Analog Input |

| Number of Monitoring Condition | 2*99 Channels |

| Data Storage Capacity | 2000 Shoots |

| Counter | 0-99999 |

| Interface | RS-485-complaint |

| Printer | Interval Printing Function/Memory Printing Function |

| Toroidal-coil | Sensitivity: x1(Option), x10 (Option) |

| Power Consumption | 80VA |

| Power Source | AC100-240V±10% 50/60Hz |

| Dimensions (mm) | 141x303x344 |

| Weight | 4.5kg |

Compact, Light Weight, and Handy Type

- Compact and Light Weight

- 3 Way Power Supply

- Equipped with Hold Display Function

- Easy Zero Adjustment Function

- Equipped with Judgment Function (Hi&Low)

FG-400 & TJ series

| Features |

FG-400 |

| Display | 4 digit (0000-9999) N: newton |

| Zeroing Adjustment | Automatic Regulation by Switching |

| Hold Function | Sample/Peak |

| Interface | RS-232C |

| Power Source | (AC100V-240V)1Φ Use by AA type battery, Ni-H type battery or Dedicated AC adapter (AC100V-240V) |

| Dimension (mm) | 77x140x27 |

| Weight | 300g |

| Features |

TJ-1A |

TJ-20R or TJ-20A |

TJ-100R or TJ-100A |

TJ-500R or TJ-500A |

| Measuring Range (N) | 0-10 | 0-196 | 0-980 | 0-4900 |

| Critical Load (N) | 20 | 294 | 1470 | 7350 |

| Accuracy | ±2% (of full scale) | |||

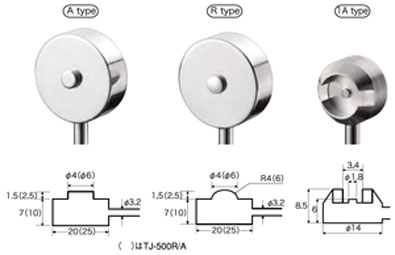

Sensor Tip Shape

Pressure Sensor |

||||

| Features | TJS-1R | TJS-20R | TJS-100R |  |

| Measuring Range (N) | 0-10 | 0-196 | 0-980 | |

| Critical Load (N) | 20 | 294 | 1470 | |

| Accuracy | ±3% (of full scale) | |||

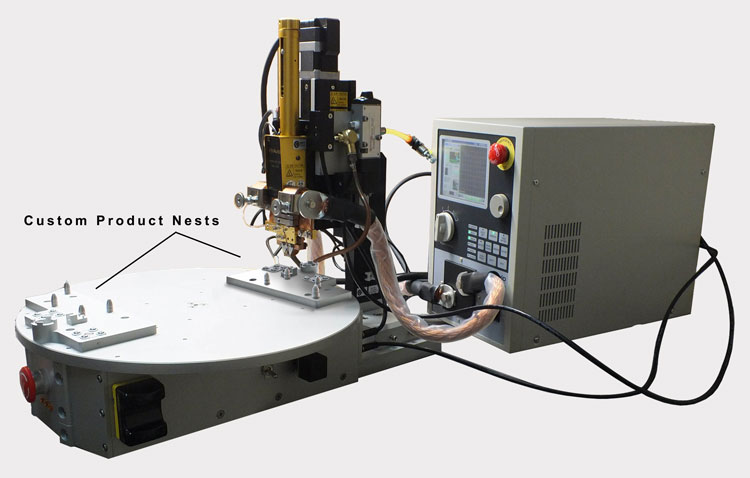

PWB Repair Machine

Compacting Unit

Can Seal Welder