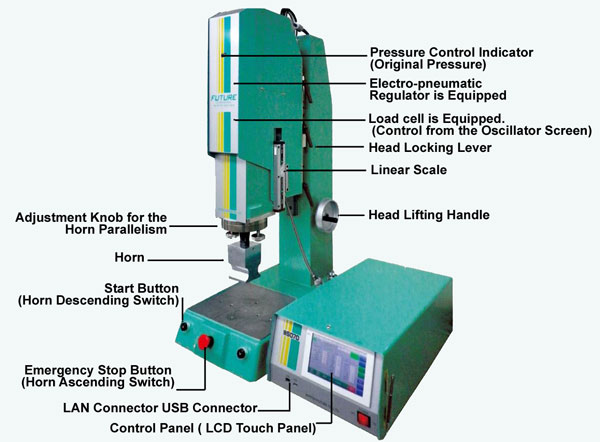

8,000W Series

Maximum Output 8,000W – World's Highest Performance in Its Class!

Includes Color LCD Display and Simple-to-Use Touch Panel

W5000 series ultrasonic plastic welders allow control of welding parameters (welding time, welding displacement, welding energy, & welding data output). A color LCD touch screen front panel provides user friendly and intuitive operation.

Welding parameter data used for controlling can be output to a network environment (LAN) or saved to a USB storage device during operation. This easily accessed parameter data history is valuable for quality control.

Color LCD display of main weld parameter waveforms is beneficial for better on-site management and analysis of the welding process.

Wide Range of Welding Management Functions

•Welding energy control and management – Maintains welding energy constant and monitors the upper and lower limits of the weld head displacement

•Welding process control and management - Holds and monitors the melting depth (DEPTH) and finished dimensions(HEIGHT)

•Management and recording of set up & welding data – Records and timestamps each welding parameter. Supports USB storage devices and connection to a network environment (LAN).

•Control and manage welding time - Delay, Oscillation period, Retention time (cooling time)

•Display of power - Displays the peak power reached during welding

•Display and record welding waveform - Frequency, air pressure, applied current, displacement of welding head, actual applied pressure and energy can be displayed and recorded

•Other Functions

• Spherical seat parallelism adjustment

• Frequency check

• 2-step pressure

• After burst

• Load cell pressure measurement and management

• 1 μm resolution welding management

• Electro-pneumatic regulator pressure control