Flex Circuits

Flex Circuits

- Most common type is polyimide (also known under the trade name of Kapton)

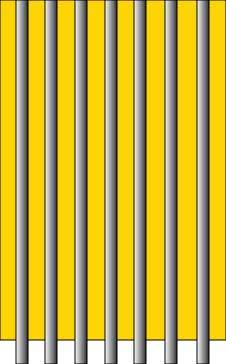

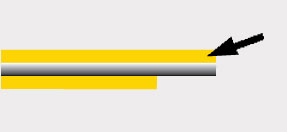

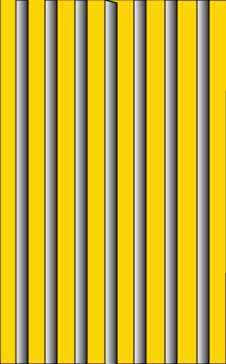

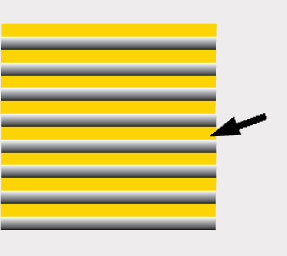

- Two layers of polyimide encapsulate the copper traces(normally 0.5–2oz)

- Copper is Rolled Annealed or Electro-Deposited (most cos teffective and widely used)

- Thickness of copper traces ranges from 0.0007–0.004 inches (18-100microns)

- Operating temperatures ranging from130–200°C (can with stand soldering temperatures up to 300°C for a short time)

- Thickness of the polyimide ranges from 0.001–0.0047inches (25-120microns)

| Type | Advantages | Disadvantages | |||

|

|

Lower thermode temperatures. | Flux contamination on thermode. Leads can be damaged or bent when handled. |

|

Maximum polyimide thickness, the top layer, needs to be .002 inches or 50 microns. Loss (thermal barrier) of 60–80°C per 25 microns thickness |

|

Single Sided | Easy to handle. Minimal flux contamination on thermode. | Higher thermode temperatures due to thermal barrier. |

|

Minimum pitch needs to be.008 inches or 200 microns to avoid short circuits. |

|

Open Windowed | Lower thermode temperatures. | Flux contamination on thermode. Part alignment is critical. |

|

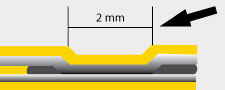

Minimum pad length needs to be .080 inches or 2 mm to allow fillets to form. |