Hot Bar Reflow Soldering

Hot Bar Reflow Soldering

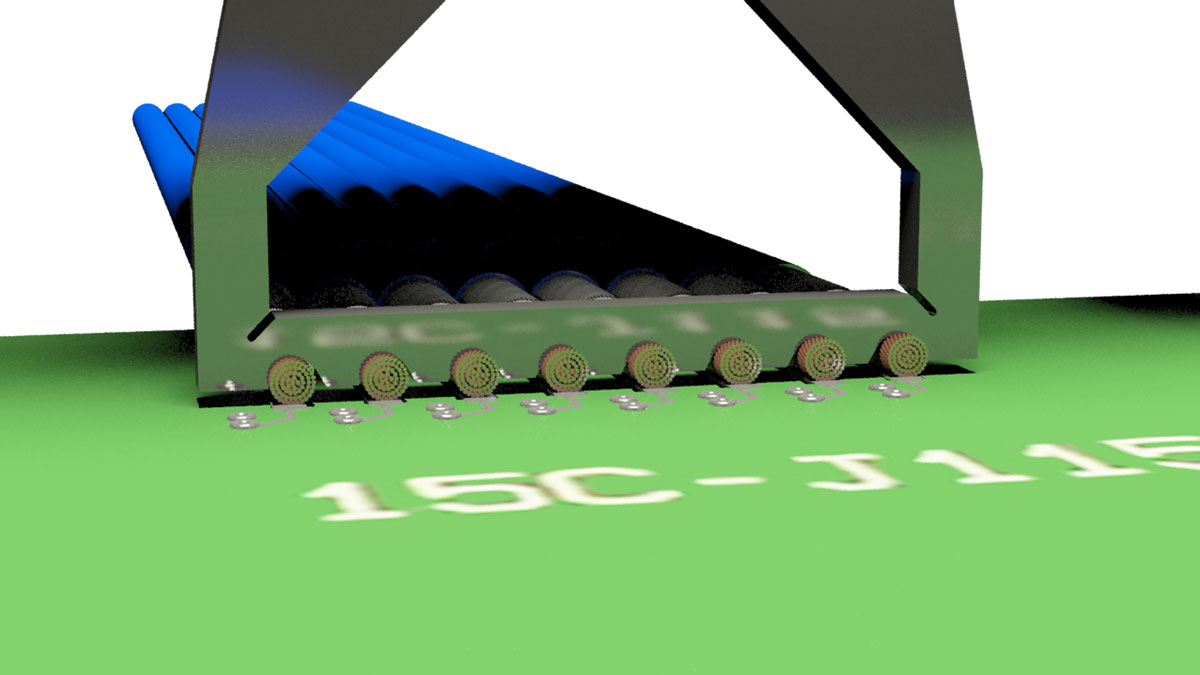

Hot Bar Reflow Soldering is a selective soldering process used to join two solder coated components. During hot bar soldering, a thermode (hot-bar) is heated to a specific temperature by a pulse heat power supply. Temperature is controlled by thermocouple feedback. The thermode is then used to apply pressure and heat over a set time period, squeezing the two solder coated components together. The thermode applies sufficient heat to cause the solder to melt and flow, after which the components are cooled under pressure, thereby creating an electro-mechanical bond between the two components.