Uncategorised

| DRILL AND COUNTERBORE SIZES FOR SOCKET HEAD CAP SCREWS | ||||||

|

||||||

| Nominal Size or Basic Screw Diameter | Nominal Drill Size | |||||

| Close Fit | Normal Fit | |||||

| Number or Fractional Size | Decimal Size | Number or Fractional Size | Decimal Size | Counterbore Diameter | Countersink Diameter | |

| A | B | C | ||||

| 0 0.0600 | 51 | 0.067 | 49 | 0.073 | 1/8 | 0.074 |

| 1 0.0730 | 46 | 0.081 | 43 | 0.089 | 5/32 | 0.087 |

| 2 0.0860 | 3/32 | 0.094 | 36 | 0.106 | 3/16 | 0.102 |

| 3 0.0990 | 36 | 0.106 | 31 | 0.120 | 7/32 | 0.115 |

| 4 0.1120 | 1/8 | 0.125 | 29 | 0.136 | 7/32 | 0.130 |

| 5 0.1250 | 9/64 | 0.141 | 23 | 0.154 | 1/4 | 0.145 |

| 6 0.1380 | 23 | 0.154 | 18 | 0.170 | 9/32 | 0.158 |

| 8 0.1640 | 15 | 0.180 | 10 | 0.194 | 5/16 | 0.188 |

| 10 0.1900 | 5 | 0.206 | 2 | 0.221 | 3/8 | 0.218 |

| 1/4 0.2500 | 17/64 | 0.266 | 9/32 | 0.281 | 7/16 | 0.278 |

| 5/16 0.3125 | 21/64 | 0.328 | 11/32 | 0.344 | 17/32 | 0.346 |

| 3/8 0.3750 | 25/64 | 0.391 | 13/32 | 0.406 | 5/8 | 0.415 |

| 7/16 0.4375 | 29/64 | 0.453 | 15/32 | 0.469 | 23/32 | 0.483 |

| 1/2 0.5000 | 33/64 | 0.516 | 17/32 | 0.531 | 13/16 | 0.552 |

| 5/8 0.6250 | 41/64 | 0.641 | 21/32 | 0.656 | 1 | 0.689 |

| 3/4 0.7500 | 49/64 | 0.766 | 25/32 | 0.781 | 1 3/16 | 0.828 |

| 7/8 0.8750 | 57/64 | 0.891 | 29/32 | 0.906 | 1 3/8 | 0.963 |

| 1 1.0000 | 1 1/64 | 1.016 | 1 1/32 | 1.031 | 1 5/8 | 1.100 |

| 1 1/4 1.2500 | 1 9/32 | 1.281 | 1 5/16 | 1.312 | 2 | 1.370 |

| 1 1/2 1.5000 | 1 17/32 | 1.531 | 1 9/16 | 1.562 | 2 3/8 | 1.640 |

| 1 3/4 1.7500 | 1 25/32 | 1.781 | 1 13/16 | 1.812 | 2 3/4 | 1.910 |

| 2 2.0000 | 2 1/32 | 2.031 | 2 1/16 | 2.062 | 3 1/8 | 2.180 |

| STANDARD SOCKET HEAD CAP SCREWS | |||||||||||

|

|||||||||||

| Nominal Size | Body Diameter | Head Diameter | Head Height | Hex. Socket Size | Fillet Ext. |

Key Engage- |

|||||

| Max | Min | Max | Min | Max | Min | Nom | Max | ||||

| D | A | H | J | F | T | ||||||

| 0 | 0.0600 | 0.0568 | 0.096 | 0.091 | 0.060 | 0.057 | 0.050 | 0.007 | 0.025 | ||

| 1 | 0.0730 | 0.0695 | 0.180 | 0.112 | 0.073 | 0.070 | 1/16 0.062 | 0.007 | 0.031 | ||

| 2 | 0.0860 | 0.0822 | 0.140 | 0.134 | 0.086 | 0.083 | 5/64 0.078 | 0.008 | 0.038 | ||

| 3 | 0.0990 | 0.0949 | 0.161 | 0.154 | 0.099 | 0.095 | 5/64 0.078 | 0.008 | 0.044 | ||

| 4 | 0.1120 | 0.1075 | 0.183 | 0.176 | 0.112 | 0.108 | 3/32 0.094 | 0.009 | 0.051 | ||

| 5 | 0.1250 | 0.1202 | 0.205 | 0.198 | 0.125 | 0.121 | 3/32 0.094 | 0.010 | 0.057 | ||

| 6 | 0.1380 | 0.1329 | 0.226 | 0.218 | 0.138 | 0.134 | 7/64 0.109 | 0.010 | 0.064 | ||

| 8 | 0.1640 | 0.1585 | 0.270 | 0.262 | 0.164 | 0.159 | 9/64 0.141 | 0.012 | 0.077 | ||

| 10 | 0.1900 | 0.1840 | 0.312 | 0.303 | 0.190 | 0.185 | 5/32 0.156 | 0.014 | 0.090 | ||

| 1/4 | 0.2500 | 0.2435 | 0.375 | 0.365 | 0.250 | 0.244 | 3/16 0.188 | 0.014 | 0.120 | ||

| 5/16 | 0.3125 | 0.3053 | 0.469 | 0.457 | 0.312 | 0.306 | 1/4 0.250 | 0.017 | 0.151 | ||

| 3/8 | 0.3750 | 0.3678 | 0.562 | 0.550 | 0.375 | 0.368 | 5/16 0.312 | 0.020 | 0.182 | ||

| 7/16 | 0.4375 | 0.4294 | 0.656 | 0.642 | 0.438 | 0.430 | 3/8 0.375 | 0.023 | 0.213 | ||

| 1/2 | 0.5000 | 0.4919 | 0.750 | 0.735 | 0.500 | 0.492 | 3/8 0.375 | 0.026 | 0.245 | ||

| 5/8 | 0.6250 | 0.6163 | 0.938 | 0.921 | 0.625 | 0.616 | 1/2 0.500 | 0.032 | 0.307 | ||

| 3/4 | 0.7500 | 0.7406 | 1.125 | 1.107 | 0.750 | 0.740 | 5/8 0.625 | 0.039 | 0.370 | ||

| 7/8 | 0.8750 | 0.8647 | 1.312 | 1.293 | 0.875 | 0.864 | 3/4 0.750 | 0.044 | 0.432 | ||

| 1 | 1.0000 | 0.9886 | 1.500 | 1.479 | 1.000 | 0.988 | 3/4 0.750 | 0.050 | 0.495 | ||

| 1 1/8 | 1.1250 | 1.1086 | 1.688 | 1.665 | 1.125 | 1.111 | 7/8 0.875 | 0.055 | 0.557 | ||

| 1 1/4 | 1.2500 | 1.2336 | 1.875 | 1.852 | 1.250 | 1.236 | 7/8 0.875 | 0.060 | 0.620 | ||

| 1 3/8 | 1.3750 | 1.3568 | 2.062 | 2.038 | 1.375 | 1.360 | 1 1.000 | 0.065 | 0.682 | ||

| 1 1/2 | 1.5000 | 1.4818 | 2.250 | 2.224 | 1.500 | 1.485 | 1 1.000 | 0.070 | 0.745 | ||

| 1 3/4 | 1.7500 | 1.7295 | 2.625 | 2.597 | 1.750 | 1.764 | 1 1/4 1.250 | 0.080 | 0.870 | ||

| 2 | 2.0000 | 1.9780 | 3.000 | 2.970 | 2.000 | 1.983 | 1 1/2 1.500 | 0.090 | 0.995 | ||

| 2 1/4 | 2.2500 | 2.2280 | 3.375 | 3.344 | 2.250 | 2.232 | 1 3/4 1.750 | 0.100 | 1.120 | ||

| 2 1/2 | 2.5000 | 2.4762 | 3.750 | 3.717 | 2.500 | 2.481 | 1 3/4 1.750 | 0.110 | 1.245 | ||

| 2 3/4 | 2.7500 | 2.7262 | 4.125 | 4.090 | 2.750 | 2.730 | 2 2.000 | 0.120 | 1.370 | ||

| 3 | 3.0000 | 2.9762 | 4.500 | 4.464 | 3.000 | 2.979 | 2 1/4 2.250 | 0.130 | 1.495 | ||

| 3 1/4 | 3.2500 | 3.2262 | 4.875 | 4.837 | 3.250 | 3.228 | 2 1/4 2.250 | 0.140 | 1.620 | ||

| 3 1/2 | 3.5000 | 3.4762 | 5.250 | 5.211 | 3.500 | 3.478 | 2 3/4 2.750 | 0.150 | 1.745 | ||

| 3 3/4 | 3.7500 | 3.7262 | 5.625 | 5.584 | 3.750 | 3.727 | 2 3/4 2.750 | 0.160 | 1.870 | ||

| 4 | 4.0000 | 3.9762 | 6.000 | 5.958 | 4.000 | 3.976 | 3 3.000 | 0.170 | 1.995 | ||

| STANDARD BUTTON HEAD CAP SCREWS | |||||

|

|||||

| Screw Size | D | A | J | S | H |

| #4 | 0.112 | 0.213 | 0.0625 | 0.015 | 0.059 |

| #6 | 0.138 | 0.262 | 0.078125 | 0.015 | 0.073 |

| #8 | 0.164 | 0.312 | 0.09375 | 0.015 | 0.087 |

| #10 | 0.19 | 0.361 | 0.125 | 0.02 | 0.101 |

| 1/4 | 0.25 | 0.437 | 0.15625 | 0.031 | 0.132 |

| 5/16 | 0.3125 | 0.547 | 0.1875 | 0.031 | 0.166 |

| 3/8 | 0.375 | 0.656 | 0.21875 | 0.031 | 0.199 |

| 1/2 | 0.5 | 0.875 | 0.3125 | 0.046 | 0.265 |

| 5/8 | 0.625 | 1 | 0.375 | 0.062 | 0.331 |

| STANDARD HEX HEAD BOLTS | |||

|

|||

| Bolt Size | Thread Diameter | Head Width | Head Height |

| A | B | C | |

| 1/4 | 0.250 | 0.438 | 0.156 |

| 5/16 | 0.313 | 0.500 | 0.203 |

| 3/8 | 0.375 | 0.562 | 0.234 |

| 7/16 | 0.438 | 0.625 | 0.281 |

| 1/2 | 0.500 | 0.750 | 0.323 |

| 9/16 | 0.563 | 0.813 | 0.359 |

| 5/8 | 0.625 | 0.938 | 0.391 |

| 3/4 | 0.750 | 1.125 | 0.483 |

| 7/8 | 0.875 | 1.313 | 0.547 |

| 1 | 1.000 | 1.500 | 0.609 |

| STANDARD SOCKET FLAT HEAD CAP SCREWS | ||||||

|

||||||

| Nominal Size | Body Diameter |

Head Diameter |

Head Height | Hexagon Socket Size | ||

| Theo-retical Sharp | Abs. Min. |

Reference | ||||

| Max | Min | Max | Nom. | |||

| D | A | H | J | |||

| 0 | 0.0600 | 0.0568 | 0.138 | 0.117 | 0.044 | 0.035 |

| 1 | 0.0730 | 0.0695 | 0.168 | 0.143 | 0.054 | 0.050 |

| 2 | 0.0860 | 0.0822 | 0.197 | 0.168 | 0.064 | 0.050 |

| 3 | 0.0990 | 0.0949 | 0.226 | 0.193 | 0.073 | 1/16 |

| 4 | 0.1120 | 0.1075 | 0.255 | 0.218 | 0.083 | 1/16 |

| 5 | 0.1250 | 0.1202 | 0.281 | 0.240 | 0.090 | 5/64 |

| 6 | 0.1380 | 0.1329 | 0.307 | 0.263 | 0.097 | 5/64 |

| 8 | 0.1640 | 0.1585 | 0.359 | 0.311 | 0.112 | 3/32 |

| 10 | 0.1900 | 0.1840 | 0.411 | 0.359 | 0.127 | 1/8 |

| 1/4 | 0.2500 | 0.2435 | 0.531 | 0.480 | 0.161 | 5/32 |

| 5/16 | 0.3125 | 0.3053 | 0.656 | 0.600 | 0.198 | 3/16 |

| 3/8 | 0.3750 | 0.3678 | 0.781 | 0.720 | 0.234 | 7/32 |

| 7/16 | 0.4375 | 0.4294 | 0.844 | 0.781 | 0.234 | 1/4 |

| 1/2 | 0.5000 | 0.4919 | 0.938 | 0.872 | 0.251 | 5/16 |

| 5/8 | 0.6250 | 0.6163 | 1.188 | 1.112 | 0.324 | 3/8 |

| 3/4 | 0.7500 | 0.7406 | 1.438 | 1.355 | 0.396 | 1/2 |

| 7/8 | 0.8750 | 0.8647 | 1.688 | 1.604 | 0.468 | 9/16 |

| 1 | 1.0000 | 0.9886 | 1.938 | 1.841 | 0.540 | 5/8 |

| 1 1/8 | 1.1250 | 1.1086 | 2.188 | 2.079 | 0.611 | 3/4 |

| 1 1/4 | 1.2500 | 1.2336 | 2.438 | 2.316 | 0.683 | 7/8 |

| 1 3/8 | 1.3750 | 1.3568 | 2.688 | 2.553 | 0.755 | 7/8 |

| 1 1/2 | 1.5000 | 1.4818 | 2.938 | 2.791 | 0.827 | 1 |

| STANDARD SHOULDER SCREWS | |||||||||

|

|||||||||

| Nominal Size | Shoulder Diameter |

Head Diameter |

Head Height |

Head Side Height |

Nominal Thread Size | Thread Length |

|||

| Max | Min | Max | Min | Max | Min | Min | |||

| D | A | H | S | D | E | ||||

| 1/4 | 0.2480 | 0.2460 | 0.375 | 0.357 | 0.188 | 0.177 | 0.157 | 10 - 24 | 0.375 |

| 5/16 | 0.3105 | 0.3085 | 0.438 | 0.419 | 0.219 | 0.209 | 0.183 | 1/4 - 20 | 0.438 |

| 3/8 | 0.3730 | 0.3710 | 0.562 | 0.543 | 0.250 | 0.240 | 0.209 | 5/16 - 18 | 0.500 |

| 1/2 | 0.4980 | 0.4960 | 0.750 | 0.729 | 0.312 | 0.302 | 0.262 | 3/8 - 16 | 0.625 |

| 5/8 | 0.6230 | 0.6210 | 0.875 | 0.853 | 0.375 | 0.365 | 0.315 | 1/2 - 13 | 0.750 |

| 3/4 | 0.7480 | 0.7460 | 1.000 | 0.977 | 0.500 | 0.490 | 0.421 | 5/8 - 11 | 0.875 |

| 1 | 0.9980 | 0.9960 | 1.312 | 1.287 | 0.625 | 0.610 | 0.527 | 3/4 - 10 | 1.000 |

| 1 1/4 | 1.2480 | 1.2460 | 1.750 | 1.723 | 0.750 | 0.735 | 0.633 | 7/8 - 9 | 1.125 |

| 1 1/2 | 1.4980 | 1.4960 | 2.125 | 2.095 | 1.000 | 0.980 | 0.842 | 1 1/8 - 7 | 1.500 |

| 1 3/4 | 1.7480 | 1.7460 | 2.375 | 2.345 | 1.125 | 1.105 | 0.948 | 1 1/4 - 7 | 1.750 |

| 2 | 1.9980 | 1.9960 | 2.750 | 2.720 | 1.250 | 1.230 | 1.054 | 1 1/2 - 6 | 2.000 |

| Nominal Size | Thread Neck Diameter |

Thread Neck Width | Shoulder Neck Diameter | Shoulder Neck Width | Thread Neck Fillet |

Head Fillet Extension Above D | Hexagon Socket Size | ||

| Max | Min | Max | Min | Max | Max | Min | Max | Nom | |

| G | I | K | F | N | M | J | |||

| 1/4 | 0.142 | 0.133 | 0.083 | 0.227 | 0.093 | 0.023 | 0.017 | 0.014 | 1/8 |

| 5/16 | 0.193 | 0.182 | 0.100 | 0.289 | 0.093 | 0.028 | 0.022 | 0.017 | 5/32 |

| 3/8 | 0.249 | 0.237 | 0.111 | 0.352 | 0.093 | 0.031 | 0.025 | 0.020 | 3/16 |

| 1/2 | 0.304 | 0.291 | 0.125 | 0.477 | 0.093 | 0.035 | 0.029 | 0.026 | 1/4 |

| 5/8 | 0.414 | 0.397 | 0.154 | 0.602 | 0.093 | 0.042 | 0.036 | 0.032 | 5/16 |

| 3/4 | 0.521 | 0.502 | 0.182 | 0.727 | 0.093 | 0.051 | 0.045 | 0.039 | 3/8 |

| 1 | 0.638 | 0.616 | 0.200 | 0.977 | 0.125 | 0.055 | 0.049 | 0.050 | 1/2 |

| 1 1/4 | 0.750 | 0.726 | 0.222 | 1.227 | 0.125 | 0.062 | 0.056 | 0.060 | 5/8 |

| 1 1/2 | 0.964 | 0.934 | 0.286 | 1.478 | 0.125 | 0.072 | 0.066 | 0.070 | 7/8 |

| 1 3/4 | 1.089 | 1.059 | 0.286 | 1.728 | 0.125 | 0.072 | 0.066 | 0.080 | 1 |

| 2 | 1.307 | 1.277 | 0.333 | 1.978 | 0.125 | 0.102 | 0.096 | 0.090 | 1 1/4 |

| METRIC BUTTON HEAD CAP SCREW | |||||

|

|||||

| Screw Size | D | A | J | S | H |

| M3 | 3 | 5.7 | 2 | 0.38 | 1.65 |

| M4 | 4 | 7.6 | 2.5 | 0.38 | 2.2 |

| M5 | 5 | 9.5 | 3 | 0.5 | 2.75 |

| M6 | 6 | 10.5 | 4 | 0.8 | 3.3 |

| M8 | 8 | 14 | 5 | 0.8 | 4.4 |

| M10 | 10 | 17.5 | 6 | 0.8 | 5.5 |

| M12 | 12 | 21 | 8 | 0.8 | 6.6 |

| METRIC FLAT SOCKET CAP SCREW | |||

|

|||

| Screw Size | C | A | B |

| M3 | 3 | 6.72 | 2 |

| M4 | 4 | 8.96 | 2.5 |

| M5 | 5 | 11.2 | 3 |

| M6 | 6 | 13.44 | 4 |

| M8 | 8 | 17.92 | 5 |

| M10 | 10 | 22.4 | 6 |

| M12 | 12 | 26.88 | 8 |

| M16 | 16 | 33.6 | 10 |

| M20 | 20 | 40.32 | 12 |

| METRIC HEX HEAD BOLT | |||

|

|||

| Bolt Size | A | B | C |

| M4 | 4 | 7 | 2.8 |

| M5 | 5 | 8 | 3.5 |

| M6 | 6 | 10 | 4 |

| M7 | 7 | 11 | 4.8 |

| M8 | 8 | 13 | 5.3 |

| M10 | 10 | 17 | 6.4 |

| M12 | 12 | 19 | 7.5 |

| M14 | 14 | 22 | 8.8 |

| M16 | 16 | 24 | 10 |

| M20 | 20 | 30 | 12.5 |

| M24 | 24 | 36 | 15 |

| Metric Socket Head Cap Screws | |||||||||

|

|||||||||

| Nom. Size and Thread Pitch | Body Diameter D |

Head Diameter A |

Head Height H |

Chamfer or Radius S |

Hexagon Socket Size J |

Key Engage- |

|||

| Max | Min | Max | Min | Max | Min | Max | Nom | Min | |

| M1.6 X 0.35 | 1.60 | 1.46 | 3.00 | 2.87 | 1.60 | 1.52 | 0.16 | 1.5 | 0.80 |

| M2 X 0.4 | 2.00 | 1.86 | 3.80 | 3.65 | 2.00 | 1.91 | 0.20 | 1.5 | 1.00 |

| M2.5 X 0.45 | 2.50 | 2.36 | 4.50 | 4.33 | 2.50 | 2.40 | 0.25 | 2.0 | 1.25 |

| M3 X 0.5 | 3.00 | 2.86 | 5.50 | 5.32 | 3.00 | 2.89 | 0.30 | 2.5 | 1.50 |

| M4 X 0.7 | 4.00 | 3.82 | 7.00 | 6.80 | 4.00 | 3.88 | 0.40 | 3.0 | 2.00 |

| M5 X 0.8 | 5.00 | 4.82 | 8.50 | 8.27 | 5.00 | 4.86 | 0.50 | 4.0 | 2.50 |

| M6 X 1 | 6.00 | 5.82 | 10.00 | 9.74 | 6.00 | 5.85 | 0.60 | 5.0 | 3.00 |

| M8 X 1.25 | 8.00 | 7.78 | 13.00 | 12.70 | 8.00 | 7.83 | 0.80 | 6.0 | 4.00 |

| M10 X 1.5 | 10.00 | 9.78 | 16.00 | 15.67 | 10.00 | 9.81 | 1.00 | 8.0 | 5.00 |

| M12 X 1.75 | 12.00 | 11.73 | 18.00 | 17.63 | 12.00 | 11.79 | 1.20 | 10.0 | 6.00 |

| M14 X 2 | 14.00 | 13.73 | 21.00 | 20.60 | 14.00 | 13.77 | 1.40 | 12.0 | 7.00 |

| M16 X 2 | 16.00 | 15.73 | 24.00 | 23.58 | 16.00 | 15.76 | 1.60 | 14.0 | 8.00 |

| M20 X 2.5 | 20.00 | 19.67 | 30.00 | 29.53 | 20.00 | 19.73 | 2.00 | 17.0 | 10.00 |

| M24 X 3 | 24.00 | 23.67 | 36.00 | 35.48 | 24.00 | 23.70 | 2.40 | 19.0 | 12.00 |

| M30 X 3.5 | 30.00 | 29.67 | 45.00 | 44.42 | 30.00 | 29.67 | 3.00 | 22.0 | 15.00 |

| M36 X 4 | 36.00 | 35.61 | 54.00 | 53.37 | 36.00 | 35.64 | 3.60 | 27.0 | 18.00 |

| M42 X 4.5 | 42.00 | 41.61 | 63.00 | 62.31 | 42.00 | 41.61 | 4.20 | 32.0 | 21.00 |

| M48 X 5 | 48.00 | 47.61 | 72.00 | 71.27 | 48.00 | 47.58 | 4.80 | 36.0 | 24.00 |

| SURFACE FINISH COMPARISON CHART | |||||||||||||

| RA is the arithmetic average deviation of the surface valleys and peaks and is often used to specify the roughness of a machined surface. RMS is the root mean square average of the profile height deviations from the mean line of the surface and is mostly used for optical surfaces. | |||||||||||||

| The term Micro means millionth. So 1 micrometer is 1 millionth of a meter, or .000001 meter. Likewise 1 microinch is 1 millionth of an inch, or .000001". The term "Micron" refers to 1 millionth of a meter, which is also equivalent to 1 thousanth of a millimeter (.001 mm), and is represented by the greek symbol μ. Ra microinch ( μ" ) is basically the same as the CLA scale, or centerline average. | |||||||||||||

| Some Useful Conversions: | |||||||||||||

| Inch = " or in | 1 microinch (μ") = 0.0254 micrometers (or microns) | ||||||||||||

| Micron = µ | 1 microinch (μ") = 0.0000254mm | ||||||||||||

| Micro Inch = µ" | 0.001" = 0.0254mm | ||||||||||||

| Micrometer = µm | |||||||||||||

| Millimeter = mm | |||||||||||||

| Below are equivalent values on various surface measurment scales, and the manufacturing methods capable of producing these finishes. | |||||||||||||

| New ISO scale numbers | 1. | 2. | 3. | 4. | 5. | 6. | 7. | 8. | 9. | 10. | 11. | 12. | |

| RMS Microinches ( μ" ) | 0.5 | 1.1 | 2.2 | 4.4 | 8.8 | 17.6 | 35.2 | 64.3 | 137.5 | 275 | 550 | 1100 | 2200 |

| RMS Micrometers ( μ m ) | 0.013 | 0.027 | 0.055 | 0.11 | 0.22 | .44 | .88 | 1.6 | 3.44 | 6.88 | 13.75 | 27.5 | 55 |

| CLA or Ra microinch ( μ" ) | 0.5 | 1 | 2 | 4 | 8 | 16 | 32 | 63 | 125 | 250 | 500 | 1000 | 2000 |

| Ra micrometer ( μ m ) | 0.012 | 0.03 | 0.05 | 0.1 | 0.2 | 0.4 | 0.8 | 1.6 | 3.2 | 6.3 | 12.5 | 25 | 50 |

| Sand Casting | |||||||||||||

| Hot Rolling | |||||||||||||

| Forging | |||||||||||||

| Permanent-Mold Casting | |||||||||||||

| Investment Casting | |||||||||||||

| Extruding | |||||||||||||

| Cold Rolling | |||||||||||||

| Diecasting | |||||||||||||

| Flame Cutting | |||||||||||||

| Sawing | |||||||||||||

| Planing | |||||||||||||

| Drilling | |||||||||||||

| EDM | |||||||||||||

| Milling | |||||||||||||

| Laser Cutting | |||||||||||||

| Reaming | |||||||||||||

| Broaching | |||||||||||||

| Turning and Boring | |||||||||||||

| Tumbling | |||||||||||||

| Roller Burnishing | |||||||||||||

| Grinding | |||||||||||||

| Honing | |||||||||||||

| Electro-Polishing | |||||||||||||

| Polishing | |||||||||||||

| Lapping | |||||||||||||

| Superfinishing | |||||||||||||

| Sheet Metal Gauge Thickness | |||

| Gauge (ga) | Standard Steel Thickness (inches) | Galvanized Steel Thickness (inches) | Aluminum Thickness (inches) |

| 3 | 0.2391 | 0.2294 | |

| 4 | 0.2242 | 0.2043 | |

| 5 | 0.2092 | 0.1819 | |

| 6 | 0.1943 | 0.162 | |

| 7 | 0.1793 | 0.1443 | |

| 8 | 0.1644 | 0.1285 | |

| 9 | 0.1495 | 0.1532 | 0.1144 |

| 10 | 0.1345 | 0.1382 | 0.1019 |

| 11 | 0.1196 | 0.1233 | 0.0907 |

| 12 | 0.1046 | 0.1084 | 0.0808 |

| 13 | 0.0897 | 0.0934 | 0.072 |

| 14 | 0.0747 | 0.0785 | 0.0641 |

| 15 | 0.0673 | 0.071 | 0.0571 |

| 16 | 0.0598 | 0.0635 | 0.0508 |

| 17 | 0.0538 | 0.0575 | 0.0453 |

| 18 | 0.0478 | 0.0516 | 0.0403 |

| 19 | 0.0418 | 0.0456 | 0.0359 |

| 20 | 0.0359 | 0.0396 | 0.032 |

| 21 | 0.0329 | 0.0366 | 0.0285 |

| 22 | 0.0299 | 0.0336 | 0.0253 |

| 23 | 0.0269 | 0.0306 | 0.0226 |

| 24 | 0.0239 | 0.0276 | 0.0201 |

| 25 | 0.0209 | 0.0247 | 0.0179 |

| 26 | 0.0179 | 0.0217 | 0.0159 |

| 27 | 0.0164 | 0.0202 | 0.0142 |

| 28 | 0.0149 | 0.0187 | 0.0126 |

| 29 | 0.0135 | 0.0172 | 0.0113 |

| 30 | 0.012 | 0.0157 | 0.01 |

| 31 | 0.0105 | 0.0142 | 0.0089 |

| 32 | 0.0097 | 0.0134 | 0.008 |

| 33 | 0.009 | 0.0071 | |

| 34 | 0.0082 | 0.0063 | |

| 35 | 0.0075 | 0.0056 | |

| 36 | 0.0067 | ||

| MATERIAL | Hardness BHN |

Machinability Rating |

|

| Alloy Steels, Cast | Material Grade | Range | Range |

| Low Carbon | 1320, 2315, 2320 | 150-300 | .52 - .32 |

| 4110, 4120, 4320, | |||

| 8020, 8620 | |||

| Medium Carbon | 1330, 1340, 2325, | 175-400 | .36 - .16 |

| 2330, 4125, 4130, | |||

| 4140, 4330, 4340, | |||

| 8030, 80B30, 8040 | |||

| 8430, 8440, 8630, | |||

| 8640, 9525, 9530, | |||

| 9535 | |||

| Alloy Steels, Wrought | |||

| Low Carbon | 4012, 4024, 4028, | 125-425 | .56 - .24 |

| 4320, 4427, 4617, | |||

| 4621, 4718, 4817, | |||

| 5015, 5120, 8115, | |||

| 8620, 8625, 8720, | |||

| 9310 | |||

| Medium Carbon | 1330, 4032, 4130, | 175-52RC | .36 - .08 |

| 4135, 4140, 4145, | |||

| 4150, 4340, 5130, | |||

| 5140, 5147, 5150, | |||

| 6150, 8630, 8637, | |||

| 8640, 8642, 9255, | |||

| 9260 | |||

| High Carbon | 50100, 51100, | ||

| 52100, M-50 | |||

| Free Machining Alloy Steels, Wrought | |||

| Medium Carbon, Resulfurized |

4140, 4150 | 150-425 | .52 - .32 |

| Medium & High Carbon Leaded |

41L30, 41L40, | 150-425 | .60 - .36 |

| 41L47, 41L50, | |||

| 43L47, 51L32, | |||

| 52L100, 86L20, | |||

| 86L40 | |||

| Armor Plate, Wrought | |||

| MIL-S-12560 | 250-300 | 0.28 | |

| Aluminum Alloys, Cast | 40-100 | 4.80 | |

| Sand and Permanent Mold | X201.0, 213.0, 242.0, | 40-125 (500 kg) |

4.80 - 3.20 |

| 8295.0, 319.0, F332.0, | |||

| 355.0, 356.0, 357.0, | |||

| 514.0, 520.0, A712.0, | |||

| 713.0, 850.0 | |||

| Die Castings | 360.0, A360.0, A380.0, | 40-125 (500 kg) |

.32 - .24 |

| 384.0, 392.0, A413.0, | |||

| 443.0 | |||

| Aluminum Alloys, Wrought | 30-150 (500 kg) |

4.80 - 3.20 | |

| EC, 1060, 1145, | |||

| 1235, 2014, 2018, | |||

| 2024, 2217, 2218, | |||

| 2618, 3004, 4032, | |||

| 5050, 5056, 5086, | |||

| 5252, 5454, 5457, | |||

| 5657, 6061, 6066, | |||

| 6101, 6262, 6951, | |||

| 7004, 7039, 7075, 7175 | |||

| Carbon Steels, Cast | 100-300 | .64 - .40 | |

| Low & Medium Carbon | 1010, 1020, 1030, | ||

| 1040, 1050 | |||

| Carbon Steels, Wrought | 85-275 | .80 - .44 | |

| Low Carbon | 1005, 1009, 1011, | ||

| 1012, 1016, 1018, | |||

| 1019, 1022,1025, | |||

| 1026, 1518 | |||

| Medium Carbon | 1030, 1035, 1038, | 125-425 | .60 - .28 |

| 1040, 1043, 1045, | |||

| 1049, 1053, 1524, | |||

| 1526, 1536 | |||

| High Carbon | 1060, 1065, 1070, | 175-375 | .44 - .28 |

| 1075, 1080, 1085, | |||

| 1090, 1547,1551, | |||

| 1561, 1572 | |||

| Free Machining Carbon Steels, Wrought | 100-150 | .80 - 1.00 | |

| Low Carbon Resulferized | 1212, 1108, 1213, 1116, | ||

| 1118, 1211, B-1112 | |||

| Medium Carbon Resulferized | 1132, 1140, 1141, 1151 | 175-425 | .72 - .28 |

| Low Carbon Leaded | 12L13, 12L14 | 100-250 | 1.12 - 1.08 |

| Ductile Cast Irons | |||

| Ferritic | 60-40-18, 65-45-12 | 140-190 | 1.00 |

| Ferritic-Pearlitic | 80-55-06 | 190-260 | .64 - .52 |

| Pearlitic-Martensitic | 100-70-03 | 240-300 | 0.40 |

| Martensitic | 120-90-02 | 270-400 | .28 - .20 |

| Austenitic (NI-RESIST Ductile) | ASTM A439: Types D-2, | 120-200 | 0.24 |

| D-2C, D-5, D-3A, D-5B | |||

| ASTM A571: Type D-2M | |||

| ASTM A439: Types | 140-275 | 0.16 | |

| D-28, D-3, D-4 | |||

| Gray Cast Irons | |||

| Ferritic | ASTM A48: Class 20 | 120-150 | 1.2 |

| SAE G1800 | |||

| Pearlitic-Ferritic | ASTM A48: Class 25 | 160-200 | 0.88 |

| SAE G2500 | |||

| Pearlitic | ASTM A48: Classes 30, | 190-220 | 0.64 |

| 35 & 40 | |||

| SAE G3000 | |||

| Pearlitic & Free Carbides | ASTM A48: Classes | 220-260 | 0.6 |

| 45 & 50 | |||

| SAE G3500, G4000 | |||

| Pearlitic or Acicular & Free Carbides | ASTM A48: Classes 55, | 250-320 | 0.32 |

| 60 & 65+ | |||

| Austenitic (NI-RESIST) | ASTM A436: Types 1, | 100-250 | .52 - .32 |

| 1b, 5 | |||

| ASTM A436: Types 2, | |||

| 3, 6 | |||

| Malleable Cast Irons | |||

| Ferritic | 32510, 35018 | 110-160 | 1.20 |

| Pearlitic | 40010, 43010, 45006, | 160-240 | .88 - .64 |

| 45008, 48005, 50005 | |||

| Martensitic | 53004, 70003, 60004, | 200-320 | .60 - .28 |

| 70002, 70004, 80002, | |||

| 90001 | |||

| Copper Alloys, Cast | |||

| 834, 838, 844, 854, | 40-150 (500 kg) |

1.6 | |

| 857, 864, 867, 928, | |||

| 934, 937,939, 944, | |||

| 957, 973, 976 | |||

| 817, 853, 872, 876, | 40-175 (500 kg) |

1.4 | |

| 905, 923, 926, 947, | |||

| 952, 958 | |||

| 801, 807, 815, 822, | 40-200 (500 kg) |

0.68 | |

| 826, 863, 907, 910, | |||

| 913, 916, 963 | |||

| Copper Alloys, Wrought | |||

| 314, 330, 353, 360, | 10RB - 100RB | 1.60 - 2.00 | |

| 367, 368, 377, 485 | |||

| 226, 230, 268, 280, | 10RB - 100RB | 1.40 - 1.60 | |

| 464, 465, 467, 675, | |||

| 770 | |||

| 102, 113, 115, 116, | 10RB - 100RB | .68 - .80 | |

| 170, 175, 505, 524, | |||

| 706, 745, 754 | |||

| High Strength Steels, Wrought | |||

| 300M, 4330V, 4340, | 225-400 43RC - 52RC |

||

| D6ac(?), H11, H13 | |||

| 325-375 43RC - 48RC |

|||

| 325-375 | |||

| High Temperature Alloys | |||

| Nickle Base, Wrought | Inconel Alloy 625, | 200-400 | .16 - .12 |

| 702, 706, 718, 721, 722, | |||

| X-750, 751, & 901 | |||

| M252 | |||

| Nimonic 75 & 80 | |||

| Waspoloy (?) | |||

| Astroloy, Inconel Alloy 700 | 225-400 | .12 - .09 | |

| Nimonic 90 & 95, Rene 41 | |||

| Udimet 500, 700, 710 | |||

| Hastelloy B, C, G, X | 140-310 | .16 - .12 | |

| Incoloy 804, 825 | |||

| Inconel Alloy 600, 604 | |||

| Refractaloy 26 | |||

| Udimet 630 | |||

| TD-Nickle | 180-200 | .48 | |

| Nickle Base, Cast | Hastelloy B & C ASTM A296 | 200-375 | 0.12 |

| Cobalt Base, Wrought | Haynes Alloy 25, 188 J-1570 | 180-320 | .16 - .08 |

| MAR-M905, MAR-M918 | |||

| S-816 | |||

| Iron Base, Wrought | A-286, Discoloy | 180-320 | .28 - .20 |

| Incoloy 800, 801, 802 | |||

| N-155 | |||

| Manganese, Wrought | |||

| 140-220 | 0.28 | ||

| Magnesium Alloys, Cast | |||

| AM100A, AZ81A, AZ918, | 40-90 (500kg) |

4.80 | |

| AZ91C, EZ33A, HZ32A, | |||

| K1A, ZE41A, ZK51A | |||

| Magnesium Alloys, Wrought | |||

| AZ21X1, AZ31C, AZ80A, | 40-90 (500kg) |

4.80 | |

| HM21A, LA141A, ZK60A | |||

| Maraging Steels, Wrought | |||

| 120 Grade | 275-325 | 0.36 | |

| 180 Grade | 375-425 | 0.28 | |

| 200 Grade, 250 Grade | 275-325 50RC-52RC |

.32 - .12 | |

| 300 Grade, 350 Grade | |||

| Nickel Alloys, Wrought & Cast | |||

| Nickel 200, 201, 205, 211, | 80-170 | 0.56 | |

| 220, 230, & 270 | |||

| Monel 400, 401, 404, | 115-240 | 0.44 | |

| and R-405 | |||

| ASTM A296: Grades CZ-100 | |||

| M-35 | |||

| Duranickel 301 | 150-360 | .16 - .12 | |

| Monel 502 & K-500 | |||

| Ni-Span-C 902 | |||

| Permanickel 300 | |||

| Nitriding Steels, Wrought | |||

| Nitralloy 125, 135, 225, 230 | 200-350 | .52 - .40 | |

| EZ & N. Nitrex 1 | |||

| Refractory Alloys, Cast, Wrought, P/M | |||

| Molybdenum | MO, TZC, Mo-50Re, TZM | 220-290 | 0.80 |

| Stainless Steels, Cast | |||

| Ferritic | ASTM A217: Grades C5, C12 | 135-185 | 0.60 |

| ASTM A296: Grades CB-30, | |||

| CC-50, CE-30 | |||

| Austenitic | ASTM A296: Grades CF-16F, | 140-170 | 0.64 |

| CN-7M | |||

| ASTM A296: Grades CF-3, | 135-185 | 0.56 | |

| CF-8, CF8C, CF-20 | |||

| ASTM A451: Grades CPF8, | |||

| CPF8C, CPF8C (Ta-Max) | |||

| ASTM A296: Grades CF-3M, | 135-185 | 0.56 | |

| CF-8M, CG-8M, CG-12, | |||

| CH20, CK20 | |||

| ASTM A-451: Grades CPF8M, | |||

| CPF10MC, CPH8, CPH10, | |||

| CPH20, CPK20 | |||

| ASTM A297: Grades HD, HE, | 160-210 | 0.28 | |

| HF, HH, HI, HK, HL, HN, | |||

| HT, HU | |||

| Martensitic | ASTM A296: Grades CA-15, | 135-225 | .48 - .40 |

| CA-40 | |||

| ASTM A426: Grades CP7, | |||

| CP9 | |||

| ASTM A296: Grades CA-15, | 275-425 | .24 - .16 | |

| CA-40 | |||

| ASTM A426: Grades CP7, | |||

| CP9 | |||

| Stainless Steels, Wrought | |||

| Ferritic | 405, 430, 436, 446, | 135-185 | 0.68 |

| 409, 434, 442, 502 | |||

| Austenitic | 201, 302, 304, 304L, | 135-275 | .64 - .44 |

| 321, 347 | |||

| 310, 310S, 314, 316, | 135-185 | 0.36 | |

| 316L, 317, 330 | |||

| Martensitic | 403, 410, 420 | 135-275 | .56 - .36 |

| 414 | |||

| Free Machinings Stainless Steels, Wrought | |||

| Ferritic | 430F, 430F Se | 135-185 | 0.96 |

| Austenitic | 230EZ, 303, 303Se, 303MA, | 135-275 | .76 - .48 |

| 303Pb, 303Cu, 303 Plus X | |||

| Martensitic | 416, 416Se, 416 Plus X, 420F, | 135-425 | .88 - .24 |

| 420F Se, 440F, 440F Se | |||

| Precipitation Hardening Stainless Steels, Cast | |||

| ACI Grade C8-7CU | 325-450 | .12 - .08 | |

| ACI Grade C0-4MO | |||

| Precipitation Hardening Stainless Steels, Wrought | |||

| 15-5 PH, 17-4 PH, 17-7 PH | 150-375 | .32 - .16 | |

| 17-14 CuMo AM-350 | |||

| AM-355, PH 13-8 Mo | |||

| PH14-8 Mo, PH 15-7 Mo | |||

| Titanium Alloys, Wrought | |||

| Commercially Pure | 99.5, 99.2, 99.0, TI-0.2Pd, | 110-275 | .96 - .64 |

| 99.0, 98.9 | |||

| Alpha and Alpha-Beta Alloys | Ti-8Mn, | 300-340 | 0.46 |

| Ti-2A1-11Sn-5Zr-1Mo, | |||

| Ti-5A1-2-5Sn, | |||

| Ti-5A1-6Sn-2Zr-1Mo, | |||

| Ti-6A1-2Sn-4Zr-2Mo-25Si | |||

| Ti-6A1-2Sn-4Zr-6Mo | |||

| Ti-6A1-4V | 310-350 | 0.36 | |

| Ti-6A1-4V-CL1 (???) | |||

| Ti-6A1-6V-2Sn | 320-370 | 0.32 | |

| Ti-7A1-4Mo | |||

| Ti-1A1-8V-5Fe | 320-380 | 0.28 | |

| Ti-6A1-4V | 320-380 | 0.24 | |

| Ti-6A1-2Sn-4Zr-2Mo | |||

| Ti-6A1-2Sn-4Zr-6Mo | |||

| Ti-4A1-3Mo-1V | 375-420 | 0.2 | |

| Ti-7A1-4Mo | |||

| Ti-1A1-8V-5Fe | 375-440 | 0.12 | |

| Beta Alloys | Ti-3A1-8V-6Cr-4Mo-4Zr | 275-440 | .20 - .09 |

| Ti-4.5Sn-6Zr-11.5Mo | |||

| Ti-13V-11Cr-3A1 | |||

| Tool Steels, Wrought | |||

| High Speed | M1, M2, M6, M10, T1, T2, | 220-275 | .32 - .20 |

| T6, M3 Type 2, T15 | |||

| M3, M7, M33, M34, M36, | 225-275 | 0.28 | |

| M41, M42, M43, M44, | |||

| M46, M47, T4, T5 | |||

| Hot Work | H10, H11, H12, | 150-375 (48Rc-50Rc) |

.32 - .08 |

| H13, H14 | |||

| H21, H24, H41, H42 | 150-250 | .32 - .24 | |

| Cold Work | A7, D4 | 200-250 | 0.2 |

| A2, A4, A8, A10, 01, 02, | 200-250 | 0.32 | |

| 06, 07 | |||

| Shock Resisting | S1, S2, S5, S7 | 175-225 | 0.44 |

| Zinc Alloys, Cast | |||

| AMS 4803A, ILZRO 12, | 80-100 | 2.00 | |

| ILZRO 13, SAE 903, SAE 925, | |||

| ZDC No. 7 | |||

| Zirconium Alloys, Wrought | |||

| Zr-2%Hf (Grade 11) | 140-280 | 1.20 | |

| Zr-0.0C1%Hf (Grade 21) | |||

| Zircaloy 2 (Grade 32) | |||

| Zircaloy 4 (Grade 34) | |||

| INCH/METRIC TAP DRILL SIZES & DECIMAL EQUIVALENTS | |||||||||||

| FRACTION OR DRILL SIZE |

DECIMAL EQUIVALENT |

TAP SIZE | FRACTION OR DRILL SIZE |

DECIMAL EQUIVALENT |

TAP SIZE | FRACTION OR DRILL SIZE |

DECIMAL EQUIVALENT |

TAP SIZE | |||

| NUMBER SIZE DRILLS 80 | 0.0135 | 9/64 ------------- | 0.1406 | U | 0.3680 | 7/16 - 14 | |||||

| 79 | 0.0145 | 27 | 0.1440 | 3/8 --------------- | 0.3750 | ||||||

| 1/64 ------------------ | 0.0156 | 26 | 0.1470 | V | 0.3770 | ||||||

| 78 | 0.0160 | 25 | 0.1495 | 10 - 24 | W | 0.3860 | |||||

| 77 | 0.0180 | 24 | 0.1520 | 25/64 ------------ | 0.3906 | 7/16 - 20 | |||||

| 76 | 0.0200 | 23 | 0.1540 | X | 0.3970 | ||||||

| 75 | 0.0210 | 5/32 ------------- | 0.1562 | Y | 0.4040 | ||||||

| 74 | 0.0225 | 22 | 0.1570 | 13/32 ------------ | 0.4062 | ||||||

| 73 | 0.0240 | 21 | 0.1590 | 10 - 32 | Z | 0.4130 | |||||

| 72 | 0.0250 | 20 | 0.1610 | 27/64 ------------ | 0.4219 | 1/2 - 13 | |||||

| 71 | 0.0260 | 19 | 0.1660 | 7/16 ------------- | 0.4375 | ||||||

| 70 | 0.0280 | 18 | 0.1695 | 29/64 ------------ | 0.4531 | 1/2 - 20 | |||||

| 69 | 0.0292 | 11/64 ------------ | 0.1719 | 15/32 ------------ | 0.4688 | ||||||

| 68 | 0.0310 | 17 | 0.1730 | 31/64 ------------ | 0.4844 | 9/16 - 12 | |||||

| 1/32 ------------------ | 0.0312 | 16 | 0.1770 | 12 - 24 | 1/2 --------------- | 0.5000 | |||||

| 67 | 0.0320 | 15 | 0.1800 | 33/64 ------------ | 0.5156 | 9/16 - 18 | |||||

| 66 | 0.0330 | 14 | 0.1820 | 12 - 28 | 17/32 ------------ | 0.5312 | 5/8 - 11 | ||||

| 65 | 0.0350 | 13 | 0.1850 | 35/64 ------------ | 0.5469 | ||||||

| 64 | 0.0360 | 3/16 ------------- | 0.1875 | 9/16 ------------- | 0.5625 | ||||||

| 63 | 0.0370 | 12 | 0.1890 | 37/64 ------------ | 0.5781 | 5/8 - 18 | |||||

| 62 | 0.0380 | 11 | 0.1910 | 19/32 ------------ | 0.5938 | ||||||

| 61 | 0.0390 | 10 | 0.1935 | 39/64 ------------ | 0.6094 | ||||||

| 60 | 0.0400 | 9 | 0.1960 | 5/8 --------------- | 0.6250 | ||||||

| 59 | 0.0410 | 8 | 0.1990 | 41/64 ------------ | 0.6406 | ||||||

| 58 | 0.0420 | 7 | 0.2010 | 1/4 - 20 | 21/32 ------------ | 0.6562 | 3/4 - 10 | ||||

| 57 | 0.0430 | 13/64 ------------ | 0.2031 | 43/64 ------------ | 0.6719 | ||||||

| 56 | 0.0465 | 6 | 0.2040 | 11/16 ------------ | 0.6875 | 3/4 - 16 | |||||

| 3/64 ------------------ | 0.0469 | 0 - 80 | 5 | 0.2055 | 45/64 ------------ | 0.7031 | |||||

| 55 | 0.0520 | 4 | 0.2090 | 23/32 ------------ | 0.7188 | ||||||

| 54 | 0.0550 | 3 | 0.2130 | 1/4 - 28 | 47/64 ------------ | 0.7344 | |||||

| 53 | 0.0595 | 1-64, 72 | 7/32 ------------- | 0.2188 | 3/4 --------------- | 0.7500 | |||||

| 1/16 ------------------ | 0.0625 | 2 | 0.2210 | 49/64 ------------ | 0.7656 | 7/8 - 9 | |||||

| 52 | 0.0635 | 1 | 0.2280 | 25/32 ------------ | 0.7812 | ||||||

| 51 | 0.0670 | LETTER SIZE DRILLS A | 0.2340 | 51/64 ------------ | 0.7969 | ||||||

| 50 | 0.0700 | 2-56, 64 | 15/64 ------------ | 0.2344 | 13/16 ------------ | 0.8125 | 7/8 - 14 | ||||

| 49 | 0.0730 | B | 0.2380 | 53/64 ------------ | 0.8281 | ||||||

| 48 | 0.0760 | C | 0.2420 | 27/32 ------------ | 0.8438 | ||||||

| 5/64 ------------------ | 0.0781 | D | 0.2460 | 55/64 ------------ | 0.8594 | ||||||

| 47 | 0.0785 | 3 - 48 | 1/4----------- E | 0.2500 | 7/8 --------------- | 0.8750 | 1 - 8 | ||||

| 46 | 0.0810 | F | 0.2570 | 5/16 - 18 | 57/64 ------------ | 0.8906 | |||||

| 45 | 0.0820 | 3 - 56 | G | 0.2610 | 29/32 ------------ | 0.9062 | |||||

| 44 | 0.0860 | 17/64 ------------ | 0.2656 | 59/64 ------------ | 0.9219 | 1 - 12 | |||||

| 43 | 0.0890 | 4 - 40 | H | 0.2660 | 15/16 ------------ | 0.9375 | |||||

| 42 | 0.0935 | 4 - 48 | I | 0.2720 | 5/16 - 24 | 61/64 ------------ | 0.9531 | ||||

| 3/32 ------------------ | 0.0938 | J | 0.2770 | 31/32 ------------ | 0.9688 | ||||||

| 41 | 0.0960 | K | 0.2810 | 63/64 ------------ | 0.9844 | 1 1/8 - 7 | |||||

| 40 | 0.0980 | 9/32 ------------- | 0.2812 | 1 ----------------- | 1.0000 | ||||||

| 39 | 0.0995 | L | 0.2900 | 1 3/64----------- | 1.0459 | 1 1/8 - 12 | |||||

| 38 | 0.1015 | 5 - 40 | M | 0.2950 | 1 7/64----------- | 1.1094 | 1 1/4 - 7 | ||||

| 37 | 0.1040 | 5 - 44 | 19/64 ------------ | 0.2969 | 1 1/8------------- | 1.1250 | |||||

| 36 | 0.1065 | 6 - 32 | N | 0.3020 | 1 11/64 ---------- | 1.1719 | 1 1/4 - 12 | ||||

| 7/64 ------------------ | 0.1094 | 5/16 ------------- | 0.3125 | 3/8 - 16 | 1 7/32 ----------- | 1.2186 | 1 3/8 - 6 | ||||

| 35 | 0.1100 | O | 0.3160 | 1 1/4------------- | 1.2500 | ||||||

| 34 | 0.1110 | P | 0.3230 | 1 19/64---------- | 1.2969 | 1 3/8 - 12 | |||||

| 33 | 0.1130 | 6 - 40 | 21/64 ------------ | 0.3281 | 1 11/32---------- | 1.3433 | 1 1/2 - 6 | ||||

| 32 | 0.1160 | Q | 0.3320 | 3/8 - 24 | 1 3/8------------- | 1.3750 | |||||

| 31 | 0.1200 | R | 0.3390 | 1 27/64---------- | 1.4219 | 1 1/2 - 12 | |||||

| 1/8 ------------------- | 0.1250 | 11/32 ------------ | 0.3438 | 1 1/2------------- | 1.5000 | ||||||

| 30 | 0.1285 | S | 0.3480 | ||||||||

| 29 | 0.1360 | 8-32, 36 | T | 0.3580 | |||||||

| 28 | 0.1405 | 23/64 ------------ | 0.3594 | ||||||||

| PIPE THREAD SIZES (NPSC) | METRIC TAP DRILL SIZES | METRIC TAP DRILL SIZES | |||||||||

| THREAD | DRILL | THREAD | DRILL | METRIC TAP | TAP DRILL mm | DECIMAL EQUIVALENT |

METRIC TAP | TAP DRILL mm | DECIMAL EQUIVALENT |

||

| 1/8 - 27 | 11/32 | 1 1/2 - 11 1/2 | 1 3/4 | M1.6 x 0.35 | 1.25 | 0.0492 | M16 x 2 | 14.00 | 0.5512 | ||

| 1/4 - 18 | 7/16 | 2 - 11 1/2 | 2 7/32 | M1.8 x 0.35 | 1.45 | 0.0571 | M16 x 1.5 | 14.50 | 0.5709 | ||

| 3/8 - 18 | 37/64 | 2 1/2 - 8 | 2 21/32 | M2 x 0.4 | 1.60 | 0.0630 | M18 x 2.5 | 15.50 | 0.6102 | ||

| 1/2 - 14 | 23/32 | 3 - 8 | 3 1/4 | M2.2 x 0.45 | 1.75 | 0.0689 | M18 x 1.5 | 16.50 | 0.6496 | ||

| 3/4 - 14 | 59/64 | 3 1/2 - 8 | 3 3/4 | M2.5 x 0.45 | 2.05 | 0.0807 | M20 x 2.5 | 17.50 | 0.6890 | ||

| 1 - 11 1/2 | 1 5/32 | 4 - 8 | 4 1/4 | M3 x 0.5 | 2.50 | 0.0984 | M20 x 1.5 | 18.50 | 0.7283 | ||

| 1 1/4 - 11 1/2 | 1 1/2 | M3.5 x 0.8 | 2.90 | 0.1142 | M22 x 2.5 | 19.50 | 0.7677 | ||||

| M4 x 0.7 | 3.30 | 0.1299 | M22 x 1.5 | 20.50 | 0.8071 | ||||||

| M4.5 x 0.75 | 3.70 | 0.1457 | M24 x 3 | 21.00 | 0.8268 | ||||||

| M5 x 0.8 | 4.20 | 0.1654 | M24 x 2 | 22.00 | 0.8661 | ||||||

| M6 x 1 | 5.00 | 0.1958 | M27 x 3 | 24.00 | 0.9449 | ||||||

| M7 x 1 | 6.00 | 0.2362 | M27 x 2 | 25.00 | 0.9813 | ||||||

| M8 x 1.25 | 6.70 | 0.2638 | M30 x 3.5 | 26.50 | 1.0433 | ||||||

| M8 x 1 | 7.00 | 0.2756 | M30 x 2 | 28.00 | 1.1024 | ||||||

| M10 x 1.5 | 8.50 | 0.3350 | M33 x 3.5 | 29.50 | 1.1614 | ||||||

| M10 x 1.25 | 8.70 | 0.3425 | M33 x 2 | 31.00 | 1.2205 | ||||||

| M12 x 1.75 | 10.20 | 0.4016 | M36 x 4 | 32.00 | 1.2598 | ||||||

| M12 x 1.25 | 10.80 | 0.4252 | M36 x 3 | 33.00 | 1.2992 | ||||||

| M14 x 2 | 12.00 | 0.4724 | M39 x 4 | 35.00 | 1.3780 | ||||||

| M14 x 1.5 | 12.50 | 0.4921 | M39 x 3 | 36.00 | 1.4173 | ||||||

Hardness Conversion Table

Approximate Hardness Equivalents Covering Range of Rockwell C and Rockwell B Scales

|

BRINELL |

ROCKWELL SCALES |

VPN |

|||||||||||||||

|

BHN |

BHN |

A |

B |

C |

D |

E |

F |

G |

H |

K |

15N |

30N |

45N |

15T |

30T |

45T |

DPH HV/10 |

|

92 |

80 |

87 |

97 |

92 |

87 |

1865 |

|||||||||||

|

92 |

79 |

86 |

96 |

92 |

87 |

1787 |

|||||||||||

|

91 |

78 |

85 |

96 |

91 |

86 |

1710 |

|||||||||||

|

91 |

77 |

84 |

96 |

91 |

85 |

1633 |

|||||||||||

|

90 |

76 |

83 |

96 |

90 |

84 |

1556 |

|||||||||||

|

90 |

75 |

83 |

95 |

89 |

83 |

1478 |

|||||||||||

|

89 |

74 |

82 |

95 |

89 |

82 |

1400 |

|||||||||||

|

89 |

73 |

81 |

95 |

88 |

81 |

1323 |

|||||||||||

|

88 |

72 |

80 |

95 |

87 |

80 |

1245 |

|||||||||||

|

87 |

71 |

80 |

94 |

87 |

79 |

1160 |

|||||||||||

|

87 |

70 |

79 |

94 |

86 |

78 |

1076 |

|||||||||||

|

86 |

69 |

78 |

94 |

85 |

77 |

1004 |

|||||||||||

|

86 |

68 |

77 |

93 |

84 |

75 |

940 |

|||||||||||

|

85 |

67 |

76 |

93 |

84 |

74 |

900 |

|||||||||||

|

85 |

66 |

75 |

93 |

83 |

73 |

865 |

|||||||||||

|

739 |

84 |

65 |

75 |

92 |

82 |

72 |

832 |

||||||||||

|

722 |

84 |

64 |

74 |

92 |

81 |

71 |

800 |

||||||||||

|

705 |

83 |

63 |

73 |

91 |

80 |

70 |

772 |

||||||||||

|

688 |

83 |

62 |

72 |

91 |

79 |

69 |

746 |

||||||||||

|

670 |

82 |

61 |

72 |

91 |

79 |

68 |

720 |

||||||||||

|

654 |

81 |

60 |

71 |

90 |

78 |

67 |

697 |

||||||||||

|

634 |

81 |

59 |

70 |

90 |

77 |

66 |

674 |

||||||||||

|

615 |

80 |

58 |

69 |

89 |

76 |

64 |

653 |

||||||||||

|

595 |

80 |

57 |

69 |

89 |

75 |

63 |

633 |

||||||||||

|

577 |

79 |

56 |

68 |

88 |

74 |

62 |

613 |

||||||||||

|

560 |

79 |

120 |

55 |

67 |

88 |

73 |

61 |

595 |

|||||||||

|

543 |

78 |

120 |

54 |

66 |

87 |

72 |

60 |

577 |

|||||||||

|

523 |

78 |

119 |

53 |

65 |

87 |

71 |

59 |

560 |

|||||||||

|

512 |

77 |

119 |

52 |

65 |

86 |

70 |

57 |

544 |

|||||||||

|

496 |

77 |

118 |

51 |

64 |

86 |

69 |

56 |

528 |

|||||||||

|

481 |

76 |

117 |

50 |

63 |

86 |

69 |

55 |

513 |

|||||||||

|

469 |

75 |

117 |

49 |

62 |

85 |

68 |

54 |

498 |

|||||||||

|

455 |

75 |

116 |

48 |

61 |

85 |

67 |

53 |

484 |

|||||||||

|

443 |

74 |

116 |

47 |

61 |

84 |

66 |

51 |

471 |

|||||||||

|

432 |

74 |

115 |

46 |

60 |

84 |

65 |

50 |

458 |

|||||||||

|

421 |

73 |

115 |

45 |

59 |

83 |

64 |

49 |

446 |

|||||||||

|

409 |

73 |

114 |

44 |

59 |

83 |

63 |

48 |

434 |

|||||||||

|

400 |

72 |

113 |

43 |

58 |

82 |

62 |

47 |

423 |

|||||||||

|

390 |

72 |

113 |

42 |

57 |

82 |

61 |

46 |

412 |

|||||||||

|

381 |

71 |

112 |

41 |

56 |

81 |

60 |

44 |

402 |

|||||||||

|

371 |

71 |

112 |

40 |

55 |

80 |

60 |

43 |

392 |

|||||||||

|

362 |

70 |

111 |

39 |

55 |

80 |

59 |

42 |

382 |

|||||||||

|

353 |

70 |

110 |

38 |

54 |

79 |

58 |

41 |

372 |

|||||||||

|

344 |

69 |

110 |

37 |

53 |

79 |

57 |

40 |

363 |

|||||||||

|

336 |

69 |

109 |

36 |

52 |

78 |

56 |

38 |

354 |

|||||||||

|

327 |

68 |

109 |

35 |

52 |

78 |

55 |

37 |

345 |

|||||||||

|

319 |

68 |

108 |

34 |

51 |

77 |

54 |

36 |

336 |

|||||||||

|

311 |

67 |

108 |

33 |

50 |

77 |

53 |

35 |

327 |

|||||||||

|

301 |

67 |

107 |

32 |

49 |

76 |

52 |

34 |

318 |

|||||||||

|

294 |

66 |

106 |

31 |

48 |

91 |

76 |

51 |

33 |

310 |

||||||||

|

286 |

66 |

105 |

30 |

48 |

91 |

75 |

50 |

31 |

302 |

||||||||

|

279 |

65 |

104 |

29 |

47 |

89 |

75 |

50 |

30 |

294 |

||||||||

|

271 |

65 |

104 |

28 |

46 |

88 |

74 |

49 |

29 |

286 |

||||||||

|

264 |

64 |

103 |

27 |

45 |

87 |

73 |

48 |

28 |

279 |

||||||||

|

258 |

64 |

103 |

26 |

45 |

86 |

73 |

47 |

27 |

272 |

||||||||

|

253 |

63 |

102 |

25 |

44 |

85 |

72 |

46 |

26 |

266 |

||||||||

|

247 |

63 |

101 |

24 |

43 |

84 |

72 |

45 |

24 |

260 |

||||||||

|

201 |

240 |

62 |

100 |

23 |

42 |

83 |

71 |

44 |

23 |

93 |

82 |

72 |

254 |

||||

|

195 |

234 |

62 |

99 |

22 |

42 |

81 |

71 |

43 |

22 |

93 |

82 |

71 |

248 |

||||

|

189 |

228 |

61 |

98 |

21 |

41 |

79 |

70 |

42 |

21 |

93 |

81 |

70 |

243 |

||||

|

184 |

222 |

61 |

97 |

20 |

40 |

78 |

69 |

42 |

20 |

92 |

81 |

69 |

238 |

||||

|

181 |

218 |

60 |

97 |

19 |

77 |

92 |

80 |

69 |

234 |

||||||||

|

179 |

214 |

59 |

96 |

18 |

76 |

92 |

80 |

68 |

230 |

||||||||

|

177 |

210 |

59 |

96 |

17 |

75 |

92 |

80 |

68 |

226 |

||||||||

|

175 |

208 |

58 |

95 |

16 |

74 |

92 |

79 |

67 |

222 |

||||||||

|

171 |

205 |

58 |

95 |

15 |

73 |

92 |

79 |

67 |

217 |

||||||||

|

169 |

203 |

58 |

94 |

14 |

73 |

91 |

79 |

66 |

213 |

||||||||

|

167 |

200 |

57 |

93 |

13 |

71 |

91 |

78 |

66 |

208 |

||||||||

|

163 |

195 |

57 |

92 |

12 |

70 |

100 |

91 |

78 |

65 |

204 |

|||||||

|

162 |

193 |

56 |

92 |

11 |

69 |

100 |

91 |

77 |

64 |

200 |

|||||||

|

160 |

190 |

56 |

91 |

10 |

68 |

100 |

90 |

77 |

64 |

196 |

|||||||

|

157 |

185 |

56 |

90 |

9 |

66 |

99 |

90 |

76 |

63 |

192 |

|||||||

|

154 |

180 |

55 |

89 |

8 |

64 |

98 |

90 |

76 |

62 |

188 |

|||||||

|

151 |

176 |

54 |

88 |

7 |

63 |

97 |

90 |

75 |

61 |

184 |

|||||||

|

148 |

172 |

54 |

87 |

6 |

61 |

97 |

89 |

75 |

60 |

180 |

|||||||

|

145 |

169 |

53 |

86 |

5 |

59 |

96 |

89 |

74 |

59 |

176 |

|||||||

|

142 |

165 |

53 |

85 |

4 |

58 |

95 |

89 |

74 |

58 |

172 |

|||||||

|

140 |

162 |

52 |

84 |

3 |

56 |

94 |

88 |

73 |

57 |

168 |

|||||||

|

137 |

159 |

51 |

83 |

2 |

54 |

93 |

88 |

72 |

56 |

164 |

|||||||

|

135 |

156 |

51 |

82 |

1 |

53 |

92 |

88 |

72 |

55 |

160 |

|||||||

|

133 |

153 |

50 |

81 |

0 |

51 |

91 |

87 |

71 |

54 |

156 |

|||||||

|

130 |

150 |

50 |

80 |

49 |

91 |

87 |

70 |

53 |

152 |

||||||||

|

128 |

147 |

49 |

79 |

48 |

90 |

87 |

70 |

52 |

148 |

||||||||

|

126 |

144 |

49 |

78 |

46 |

89 |

86 |

69 |

51 |

144 |

||||||||

|

124 |

141 |

48 |

77 |

44 |

88 |

86 |

68 |

50 |

141 |

||||||||

|

122 |

139 |

47 |

76 |

43 |

87 |

86 |

68 |

49 |

139 |

||||||||

|

120 |

137 |

47 |

75 |

100 |

41 |

86 |

85 |

67 |

49 |

137 |

|||||||

|

118 |

135 |

46 |

74 |

99 |

39 |

85 |

85 |

66 |

48 |

135 |

|||||||

|

116 |

132 |

46 |

73 |

99 |

38 |

85 |

85 |

66 |

47 |

132 |

|||||||

|

114 |

130 |

45 |

72 |

98 |

36 |

84 |

84 |

65 |

46 |

130 |

|||||||

|

112 |

127 |

45 |

71 |

100 |

98 |

35 |

83 |

84 |

64 |

45 |

127 |

||||||

|

110 |

125 |

44 |

70 |

100 |

97 |

33 |

82 |

84 |

64 |

44 |

125 |

||||||

|

109 |

123 |

44 |

69 |

99 |

96 |

31 |

81 |

83 |

63 |

43 |

123 |

||||||

|

107 |

121 |

43 |

68 |

98 |

96 |

30 |

80 |

83 |

62 |

42 |

120 |

||||||

|

106 |

119 |

43 |

67 |

98 |

95 |

28 |

79 |

83 |

62 |

41 |

118 |

||||||

|

104 |

117 |

42 |

66 |

97 |

95 |

27 |

78 |

82 |

61 |

40 |

116 |

||||||

|

102 |

116 |

42 |

65 |

96 |

94 |

25 |

78 |

82 |

60 |

39 |

115 |

||||||

|

101 |

114 |

42 |

64 |

96 |

94 |

24 |

77 |

82 |

60 |

38 |

114 |

||||||

|

99 |

112 |

41 |

63 |

95 |

93 |

22 |

76 |

81 |

59 |

37 |

113 |

||||||

|

98 |

110 |

41 |

62 |

95 |

92 |

21 |

75 |

81 |

58 |

36 |

112 |

||||||

|

96 |

108 |

40 |

61 |

94 |

92 |

19 |

74 |

81 |

57 |

35 |

111 |

||||||

|

95 |

107 |

40 |

60 |

93 |

91 |

18 |

73 |

81 |

57 |

34 |

110 |

||||||

|

94 |

106 |

39 |

59 |

93 |

91 |

16 |

72 |

80 |

56 |

32 |

108 |

||||||

|

92 |

104 |

39 |

58 |

92 |

90 |

15 |

71 |

80 |

55 |

31 |

107 |

||||||

|

91 |

102 |

38 |

57 |

91 |

90 |

13 |

71 |

80 |

55 |

30 |

106 |

||||||

|

90 |

101 |

38 |

56 |

91 |

89 |

12 |

70 |

79 |

54 |

29 |

105 |

||||||

|

89 |

99 |

38 |

55 |

90 |

88 |

10 |

69 |

79 |

53 |

28 |

104 |

||||||

|

87 |

37 |

54 |

90 |

88 |

9 |

68 |

79 |

53 |

27 |

103 |

|||||||

|

86 |

37 |

53 |

89 |

87 |

7 |

67 |

78 |

52 |

26 |

102 |

|||||||

|

85 |

36 |

52 |

88 |

87 |

6 |

66 |

78 |

51 |

25 |

101 |

|||||||

|

84 |

36 |

51 |

88 |

86 |

4 |

65 |

78 |

51 |

24 |

100 |

|||||||

|

83 |

35 |

50 |

87 |

86 |

3 |

65 |

77 |

50 |

23 |

100 |

|||||||

|

82 |

35 |

49 |

87 |

85 |

64 |

77 |

49 |

22 |

99 |

||||||||

|

81 |

35 |

48 |

86 |

85 |

63 |

77 |

49 |

21 |

98 |

||||||||

|

80 |

34 |

47 |

85 |

84 |

62 |

76 |

48 |

20 |

97 |

||||||||

|

79 |

34 |

46 |

85 |

83 |

61 |

76 |

47 |

19 |

96 |

||||||||

|

79 |

33 |

45 |

84 |

83 |

60 |

76 |

46 |

18 |

95 |

||||||||

|

78 |

33 |

44 |

84 |

82 |

59 |

75 |

46 |

17 |

95 |

||||||||

|

77 |

32 |

43 |

83 |

82 |

58 |

75 |

45 |

16 |

94 |

||||||||

|

76 |

32 |

42 |

82 |

81 |

58 |

75 |

44 |

15 |

93 |

||||||||

|

75 |

31 |

41 |

82 |

81 |

57 |

74 |

44 |

14 |

92 |

||||||||

|

74 |

31 |

40 |

81 |

80 |

56 |

74 |

43 |

13 |

91 |

||||||||

|

74 |

31 |

39 |

80 |

79 |

55 |

74 |

42 |

11 |

90 |

||||||||

|

73 |

30 |

38 |

80 |

79 |

54 |

73 |

42 |

10 |

90 |

||||||||

|

72 |

30 |

37 |

79 |

78 |

53 |

73 |

41 |

9 |

89 |

||||||||

|

71 |

29 |

36 |

79 |

78 |

100 |

52 |

73 |

40 |

8 |

88 |

|||||||

|

71 |

29 |

35 |

78 |

77 |

100 |

52 |

72 |

40 |

7 |

88 |

|||||||

|

70 |

28 |

34 |

77 |

77 |

99 |

51 |

72 |

39 |

6 |

87 |

|||||||

|

69 |

28 |

33 |

77 |

76 |

99 |

50 |

72 |

38 |

5 |

87 |

|||||||

|

68 |

28 |

32 |

76 |

75 |

99 |

49 |

71 |

38 |

4 |

86 |

|||||||

|

68 |

27 |

31 |

76 |

75 |

98 |

48 |

71 |

37 |

3 |

86 |

|||||||

|

67 |

27 |

30 |

75 |

74 |

98 |

47 |

71 |

36 |

2 |

85 |

|||||||

|

66 |

26 |

29 |

74 |

74 |

98 |

46 |

70 |

36 |

1 |

85 |

|||||||

|

66 |

26 |

28 |

74 |

73 |

97 |

45 |

70 |

35 |

84 |

||||||||

|

65 |

25 |

27 |

73 |

73 |

97 |

45 |

70 |

34 |

84 |

||||||||

|

65 |

25 |

26 |

73 |

72 |

97 |

44 |

69 |

33 |

83 |

||||||||

|

64 |

24 |

25 |

72 |

71 |

96 |

42 |

69 |

33 |

83 |

||||||||

|

64 |

24 |

24 |

71 |

71 |

96 |

42 |

69 |

32 |

82 |

||||||||

|

63 |

24 |

23 |

71 |

70 |

96 |

41 |

68 |

31 |

82 |

||||||||

|

63 |

23 |

22 |

70 |

70 |

95 |

40 |

68 |

31 |

81 |

||||||||

|

62 |

23 |

21 |

70 |

69 |

95 |

39 |

68 |

30 |

81 |

||||||||

|

62 |

22 |

20 |

69 |

69 |

95 |

38 |

68 |

29 |

80 |

||||||||

|

61 |

22 |

19 |

68 |

68 |

94 |

38 |

67 |

29 |

80 |

||||||||

|

61 |

21 |

18 |

68 |

67 |

94 |

37 |

67 |

28 |

79 |

||||||||

|

60 |

79 |

17 |

67 |

67 |

93 |

36 |

67 |

27 |

79 |

||||||||

|

60 |

78 |

16 |

67 |

66 |

93 |

35 |

66 |

26 |

78 |

||||||||

|

59 |

78 |

15 |

66 |

66 |

93 |

34 |

66 |

26 |

78 |

||||||||

|

59 |

77 |

14 |

65 |

65 |

92 |

33 |

66 |

25 |

77 |

||||||||

|

58 |

77 |

13 |

65 |

65 |

92 |

32 |

65 |

24 |

77 |

||||||||

|

58 |

76 |

12 |

64 |

64 |

92 |

32 |

65 |

24 |

76 |

||||||||

|

57 |

76 |

11 |

64 |

64 |

91 |

31 |

65 |

23 |

76 |

||||||||

|

57 |

75 |

10 |

63 |

63 |

91 |

30 |

64 |

22 |

75 |

||||||||

|

56 |

75 |

9 |

62 |

62 |

91 |

29 |

64 |

22 |

75 |

||||||||

|

56 |

74 |

8 |

62 |

62 |

90 |

28 |

64 |

21 |

74 |

||||||||

|

56 |

74 |

7 |

61 |

61 |

90 |

27 |

63 |

20 |

74 |

||||||||

|

55 |

73 |

6 |

61 |

61 |

90 |

26 |

63 |

20 |

73 |

||||||||

|

55 |

73 |

5 |

60 |

60 |

89 |

26 |

63 |

19 |

73 |

||||||||

|

55 |

72 |

4 |

59 |

60 |

89 |

25 |

62 |

18 |

72 |

||||||||

|

54 |

72 |

3 |

59 |

59 |

88 |

24 |

62 |

17 |

72 |

||||||||

|

54 |

71 |

2 |

58 |

58 |

88 |

23 |

62 |

17 |

71 |

||||||||

|

53 |

71 |

1 |

58 |

58 |

88 |

22 |

61 |

16 |

71 |

||||||||

|

53 |

70 |

0 |

57 |

57 |

87 |

21 |

61 |

15 |

70 |

||||||||

|

BHN |

BHN |

A |

B |

C |

D |

E |

F |

G |

H |

K |

15N |

30N |

45N |

15T |

30T |

45T |

DPH |

|

BRINELL |

ROCKWELL SCALES |

VPN |

|||||||||||||||

| ELECTRODE SELECTION GUIDE | |

| The number which follows each material is the RWMA (Resistance Welder Manufacturers' Association) number of the electrode which would normally be placed against that material. For Example, when welding Alumel to Consil, a RWMA -2 electrode should be used on the Alumel side, and a RWMA -11 on the Consil side. Not all combinations have been tried successfully. | |

| Material | RWMA Electrode Type |

| Alumel | -2 |

| Aluminum | -1 |

| Aluminum Alloys | -1 |

| Beryllium Copper | -2 |

| Brass | -2, -11 |

| Brass, Tinned | -14 |

| Bronze | -2 |

| Cadmium Plating | -1 |

| Chromel | -2 |

| Consil | -11 |

| Constantin | -2 |

| Copel | -2 |

| Copper | -14 |

| Copper, Tinned | -14 |

| Dumet | -2 |

| Dumet, Gold Plated | -2 |

| Evenohm | -14 |

| Gold | -11 |

| Hastalloy | -2 |

| Inconel | -2 |

| Invar | -2 |

| Iridium | -2 |

| Iron | -2 |

| Karma | -2 |

| Kovar | -2 |

| Kovar, Gold Plated | -2 |

| Kulgrid | -2 |

| Magnesium | -1 |

| Manganin | -2 |

| Molybdenum | -2 |

| Nichrome | -2 |

| Nickel | -2 |

| Nickel Alloy | -2 |

| NiSpan C | -2 |

| Nioblum | -2 |

| Paliney 7 | -2 |

| Palladium | -14 |

| Platinum | -2 |

| Rhenium | -2 |

| Silver | -11 |

| Steel, Cold Rolled | -2 |

| Steel, Stainless | -2 |

| Tantalum | -2 |

| Titanium | -2 |

| Tungsten | -2 |

| Zinc | -14 |

| DENSITIES | |||

| MATERIAL | DENSITY LOWEST | DENSITY HIGHEST | LINEAR THERMAL EXPANSION |

| Metals | Lbs / in3 | Lbs / in3 | (Microinch/inch)/degrees F. |

| Admiralty Brass | 0.30798515 | 11.2 | |

| Aluminum | 0.09797721 | 13.1 | |

| Aluminum - melted | 0.09248586 | 0.09537605 | |

| Aluminum bronze (3-10% Al) | 0.27818013 | 0.31430742 | 9 |

| Aluminum foil | 0.09754368 | 0.09935005 | |

| Antifriction metal | 0.32984216 | 0.38294927 | |

| Beryllium | 0.06647421 | 6.7 | |

| Beryllium copper | 0.29263105 | 0.29805014 | 9.3 |

| Brass - casting | 0.30346924 | 0.31430742 | |

| Brass - rolled and drawn | 0.30455305 | 0.31539124 | |

| Bronze - lead | 0.27818013 | 0.31430742 | |

| Bronze - phosphorous | 0.31719761 | 0.32225543 | |

| Bronze (8-14% Sn) | 0.26734195 | 0.32153288 | |

| Cast iron | 0.24566557 | 0.28179286 | 5.8 |

| Chemical Lead | 0.40968347 | ||

| Cobolt | 0.31596928 | 6.7 | |

| Copper | 0.32261670 | 9.8 | |

| Cupronickel | 0.32297797 | 9 | |

| Delta metal | 0.31069469 | ||

| Electrum | 0.30346924 | 0.32153288 | |

| Gold | 0.69797924 | 7.9 | |

| Graphite | 0.08128640 | ||

| Hastelloy | 0.33399680 | ||

| Inconel | 0.30697358 | 6.4 | |

| Incoloy | 0.28999376 | 8 | |

| Iron | 0.28359923 | ||

| Lead | 0.40968347 | ||

| Light alloy based on Al | 0.09248586 | 0.10115641 | |

| Light alloy based on Mg | 0.06358403 | 0.06755803 | |

| Magnesium | 0.06278923 | 12 | |

| Manganese Bronze | 0.30198802 | 11.8 | |

| Mercury | 0.49107825 | ||

| Molybdenum | 0.36806483 | 3 | |

| Monel | 0.30202414 | 0.31936524 | 7.8 |

| Nickel | 0.31792015 | ||

| Nickel silver | 0.30346924 | 0.32153288 | |

| Platinum | 0.77312401 | 5 | |

| Plutonium | 0.71589838 | 19.84 | |

| Red Brass | 0.31596928 | 10.4 | |

| Silver | 0.37897527 | 11 | |

| Solder 50/50 Pb Sn | 0.32099097 | ||

| Steel | 0.28359923 | ||

| Steel, tool | 0.27872204 | ||

| Wrought Iron | 0.27998650 | ||

| Carbon Tool Steel | 0.28251541 | ||

| Steel, cold-drawn | 0.28287668 | ||

| Carbon Steel | 0.28323795 | ||

| Steel, C1020, HR | 0.28359923 | ||

| Iron | 0.28396050 | ||

| 1% carbon | 0.28287668 | ||

| Cold drawn | 0.28287668 | ||

| Framing | 0.28356310 | ||

| Soft (0.06% C) | 0.28432177 | ||

| Ore (Hematite) | 0.18807867 | ||

| Cast (pig) | 0.26040551 | ||

| Metal | 0.28396050 | ||

| Ore (Magnetite) | 0.18229831 | ||

| Oxide pigment | 0.01445092 | ||

| Pyrites | 0.08670550 | ||

| Stainless (Type 304) | 0.29010214 | ||

| Stainless (Type 347) | 0.28179286 | ||

| Stainless (27CR) | 0.26987086 | ||

| Stainless 18Cr-8Ni | 0.29010214 | ||

| Tantalum | 0.59971301 | 3.6 | |

| Tin | 0.26300667 | 12.8 | |

| Titanium | 0.16257281 | 4.8 | |

| Tungsten | 0.70809488 | ||

| Uranium | 0.68280578 | 7.4 | |

| Vanadium | 0.19848333 | 4.4 | |

| White metal | 0.25650376 | ||

| Wrought Iron | 0.27998650 | ||

| Zinc | 0.25776821 | ||

| Air (20 degrees C, 76 cm Hg) | 0.00004353 | ||

| Ammonia (liquid) | 0.02785414 | ||

| Ammonium Nitrate | 0.02637292 | ||

| Amonium Sulphate | |||

| Dry | 0.04082384 | 0.03215329 | |

| Wet | 0.04660420 | 0.02348274 | |

| Apples | 0.02315759 | 0.07225458 | |

| Asbestos | 0.07948004 | ||

| Ashes | 0.06141639 | ||

| Wet | 0.02637292 | ||

| Dry | 0.02059256 | ||

| Asphalt | 0.03974002 | ||

| Asphalt (crushed) | 0.02604778 | ||

| Bakelite (typical) | 0.04335275 | ||

| Baking Powder | 0.02604778 | ||

| Barium | |||

| Barite (barium sulfate) | 0.16257281 | ||

| Elemental | 0.12644552 | ||

| Bauxite | |||

| Solid | 0.10877927 | ||

| Crushed | 0.04627906 | ||

| Beeswax | 0.03471833 | 0.07225458 | |

| Bentonite | 0.02142348 | ||

| Benzene | 0.02662581 | ||

| Beryllium | 0.06683549 | ||

| Bismuth | 0.35332490 | 7.2 | |

| Bone | 0.06141639 | ||

| Brick | |||

| Common red | 0.06943665 | 0.05563603 | |

| Fire clay | 0.08681388 | ||

| Silica | 0.07406094 | ||

| Chrome | 0.10126479 | ||

| Magnesia | 0.09259424 | ||

| Butter | 0.03106947 | ||

| Cadmium | 0.31250106 | ||

| Calcium | 0.05599730 | ||

| Cardboard | 0.02489170 | 0.05563603 | |

| Cellulose | |||

| Amorph | 0.04696548 | ||

| Wood | 0.01806365 | ||

| Cement | |||

| Clinker | 0.04660420 | ||

| Portland | 0.05440770 | ||

| Mortar | 0.07810720 | ||

| Slurry | 0.05209555 | ||

| Ceramic | |||

| Alumina | 0.14089643 | ||

| Aluminosilicate | 0.09393095 | ||

| Boron Carbide | 0.09031823 | ||

| Glass | 0.09393095 | ||

| Iron Slag | 0.09953068 | ||

| Graphitte | 0.07814333 | ||

| Lead Glass | 0.10115641 | ||

| Quartz Glass | 0.07948004 | ||

| Sapphire - 3.99 | 0.14414789 | ||

| Tungsten Carbide | 0.56719845 | ||

| Zirconia | 0.20773192 | 0.01589601 | |

| Zirconium Carbide | 0.23699502 | ||

| Cesium - 1.873 | 0.06766641 | ||

| Charcoal | |||

| Oak | 0.02059256 | ||

| Pine | 0.01011564 | ||

| Chalk | |||

| Solid | 0.09028210 | ||

| Lumpy | 0.05209555 | ||

| Fine | 0.04049869 | ||

| Charcoal | 0.00751448 | ||

| Cinders | |||

| Furnace | 0.03298422 | ||

| Coal ash | 0.02315759 | ||

| Clay | |||

| Compacted | 0.06307825 | ||

| Dry excavated | 0.03934262 | ||

| Dry lump | 0.03876458 | 0.05419094 | |

| Fire | 0.04920537 | 0.06502912 | |

| Wet excavated | 0.06596843 | ||

| Wet lump | 0.05787592 | ||

| Coal | |||

| Bituminous | 0.04335275 | ||

| Anthracite | 0.05057821 | ||

| Coke | 0.04338888 | ||

| Lignite | 0.04515911 | ||

| Cobalt | 0.31792015 | ||

| Concrete | |||

| Limestone w/Portland | 0.08562168 | ||

| Gravel - 2.400 | 0.08670550 | ||

| Copper | 0.32261670 | ||

| Cork | 0.12716806 | ||

| Solid | 0.00867055 | ||

| Ground | 0.00578037 | ||

| Crushed Stone | 0.05780366 | ||

| Deuterium | 0.00059610 | ||

| Diamond | 0.10874314 | ||

| Earth | |||

| Dense | 0.07232683 | ||

| Fullers, raw | 0.02431367 | ||

| Loam, dry excavated | 0.05202330 | ||

| Moist, excavated | 0.05209555 | ||

| Packed | 0.05498574 | ||

| Soft loose mud | 0.06250021 | ||

| Wet, excavated | 0.05787592 | ||

| Ethyl Alcohol | 0.02897409 | 0.14812189 | |

| Fiberglass Insulation | 0.00115607 | ||

| Film emulsion | 0.13782561 | ||

| Fuel oil (medium weight) | 0.03215329 | ||

| Garbage (household rubbish) | 0.01737723 | ||

| Garnet grit | 0.14089643 | 0.07008694 | |

| Gasoline | 0.02604778 | 0.10115641 | |

| Gelatin | 0.04588166 | 0.26011649 | |

| Glass | |||

| Borosilicate | 0.08056386 | ||

| Broken or cullet | 0.04660420 | ||

| Crown | 0.09031823 | ||

| Flint | 0.13367097 | ||

| Fused silica | 0.07948004 | ||

| Lead | 0.23121466 | ||

| Lead crystal | 0.11199460 | ||

| Plate (avg.) | 0.08670550 | ||

| Window | 0.09317228 | ||

| Glue | |||

| Animal, flaked | 0.02026741 | ||

| Vegetable, powdered | 0.02315759 | ||

| Gold | |||

| Pure | 0.69797924 | ||

| Coin | 0.64631722 | ||

| Graphite (flake) | 0.02315759 | ||

| Gravel | |||

| Loose, dry | 0.05491348 | ||

| With sand , natural | 0.06936440 | 0.05780366 | |

| Dry, 1/4 to 2 inch | 0.06076610 | ||

| Wet, 1/4 to 2 inch | 0.07232683 | ||

| Gypsum | |||

| Solid | 0.10068676 | ||

| Broken | 0.04660420 | ||

| Crushed | 0.05787592 | ||

| Pulverized | 0.04017355 | ||

| Helium | 0.00000645 | ||

| Hydrogen | 0.00000325 | ||

| Ice | |||

| Crushed | 0.02142348 | ||

| Solid | 0.03320098 | ||

| Indium | 0.26842576 | ||

| Sulphate (pickling tank), dry | 0.04335275 | ||

| Sulphate (pickling tank), wet | 0.04660420 | ||

| Wrought | 0.27341133 | ||

| Ivory | 0.06611294 | 0.06936440 | |

| Leather (common) | 0.03417642 | ||

| Limestone | 0.09895265 | ||

| Linoleum | 0.04263020 | ||

| Lithium Fluoride | 0.09537605 | ||

| Lumber (Framing, douglas Fir) | 0.02026741 | ||

| Manure | 0.01445092 | ||

| Marble (calcium carbonate) | 0.09031823 | 0.10476914 | |

| Methyl Alcohol | 0.02922698 | ||

| Mineral Oil | 0.03302034 | ||

| Mud | |||

| Fluid | 0.06250021 | ||

| Packed | 0.06885861 | ||

| Muscle - ~1 | |||

| Mylar | 0.05021693 | ||

| Nylon | 0.03937875 | 0.04118511 | |

| Oil | |||

| Cake | 0.02835992 | ||

| Linseed | 0.03403191 | ||

| Petroleum | 0.03182814 | ||

| Oyster Shells (ground) | 0.03067207 | ||

| Paper | 0.02528910 | 0.04338888 | |

| Paraffin | 0.03244231 | ||

| Peat | |||

| Dry | 0.01445092 | ||

| Moist | 0.02893796 | ||

| Wet | 0.04049869 | ||

| Plaster | 0.03067207 | ||

| Plastic | |||

| HDPE | 0.03450156 | ||

| Kevlar (149) | 0.05310712 | ||

| Kevlar (29) | 0.05202330 | ||

| Polyurethane | 0.03612729 | ||

| Rubber | 0.05440770 | ||

| Platinum | 0.76951128 | 5 | |

| Plexiglass (Lucite) | 0.04190766 | 0.04335275 | |

| Plutonium | 0.62680848 | 19.84 | |

| Polyethylene | 0.03323711 | ||

| Polymethyl methacrylate (Lucite | 0.04299148 | ||

| Polystyrene | 0.03721111 | 0.03865620 | |

| Polystyrene Insulation | |||

| Extruded | 0.00104769 | ||

| Expanded | 0.00086705 | ||

| Polyurethane Insulation | 0.00086705 | ||

| Porcelain | 0.08309277 | 0.09031823 | |

| Potassium | 0.03143074 | 46 | |

| Pyrex glass | 0.08056386 | ||

| Quartz | |||

| Solid | 0.09548443 | ||

| Lump | 0.05614181 | ||

| Sand | 0.04338888 | ||

| Rip-Rap | 0.05787592 | ||

| Rock salt | 0.07875749 | ||

| Rock | |||

| Excavated with shovel | 0.05780366 | 0.06430658 | |

| Sandstone | 0.08670550 | ||

| Limestone | 0.10513041 | ||

| Granite | 0.08851186 | ||

| Rubber | |||

| Caoutchouc | 0.03414029 | ||

| Ground scrap | 0.01737723 | ||

| Manufactured | 0.05498574 | ||

| Natural | 0.03323711 | ||

| Butadiene copolymer | 0.03305647 | ||

| Neoprene | 0.04443657 | ||

| Sand | |||

| Bank | 0.05357677 | ||

| Dry | 0.05787592 | ||

| Loose | 0.05209555 | ||

| Torpedo | 0.05787592 | ||

| Water-filled | 0.06943665 | ||

| Wet | 0.06943665 | ||

| Wet, packed | 0.07521702 | ||

| With gravel, dry | 0.05961003 | ||

| With gravel, wet | 0.07297713 | ||

| Sea Water | 0.03703047 | ||

| Sewage sludge | 0.02604778 | ||

| Silicon dioxide | 0.08381531 | ||

| Silicon | 0.08742804 | 2.8 | |

| Slag | |||

| Solid | 0.07586731 | 0.14089643 | |

| Broken | 0.06365628 | ||

| Crushed, 1/4 inch | 0.04281084 | ||

| Snow | |||

| Compacted | 0.01734110 | ||

| Freshly fallen | 0.00578037 | ||

| Soap | |||

| Solid | 0.02893796 | ||

| Chips | 0.00578037 | ||

| Flakes | 0.00578037 | ||

| Powdered | 0.01329484 | ||

| Sodium | 39 | ||

| Elemental | 0.03507960 | ||

| Sodium Iodide | 0.13258715 | ||

| Starch | 0.05527475 | ||

| Stone | |||

| Crushed | 0.05787592 | ||

| Common, generic | 0.09086013 | ||

| Sugar | |||

| Brown | 0.02604778 | ||

| Powdered | 0.02893796 | ||

| Granulated | 0.02893796 | ||

| Raw cane | 0.03471833 | ||

| Talc | 0.09754368 | 0.10115641 | |

| Tar | 0.04165477 | ||

| Tobacco | 0.01156073 | ||

| Thorium | 0.41907656 | 6.7 | |

| Vegetable Oil | 0.03359838 | ||

| Vernucykute 0 | 0.02315759 | ||

| Water | |||

| Pure (at 20 degrees C) | 0.03612729 | ||

| Sea | 0.03706660 | ||

| Wood | |||

| Alder | 0.01517346 | 0.02456656 | |

| Apple | 0.02384401 | 0.03034692 | |

| Ash | 0.01842492 | ||

| Balsa | 0.00397400 | 0.00505782 | |

| Bamboo | 0.01119946 | 0.01445092 | |

| Birch | 0.02546974 | ||

| Cedar | 0.01770237 | 0.02059256 | |

| Dogwood | 0.02745674 | ||

| Mahogany | 0.02546974 | ||

| Oak | 0.02781801 | ||

| Pressed pulp board | 0.00686419 | ||

| Red Oak | 0.02431367 | ||

| Southern Pine | 0.02348274 | ||

| Sugar Maple | 0.02489170 | ||

| Walnut | 0.02142348 | ||

| White Pine | 0.02420528 | ||

THANK YOU FOR YOUR INQUIRY!

PROVIDING YOU WITH acf bonding EQUIPMENT, RENTALS, THERMODES, AND SUPPORT FOR YOUR acf bonding PROJECT.

![]() High quality hot bar ACF Bonding machines

High quality hot bar ACF Bonding machines

![]() Lower prices on equipment and hotbars (thermodes) than other manufacturers

Lower prices on equipment and hotbars (thermodes) than other manufacturers

![]() Shorter lead time

Shorter lead time

![]() Custom solutions and unparalleled customer support

Custom solutions and unparalleled customer support

ACF BONDING

How We Can Help You

AIT provides machines, hot-bars, custom tooling, and process engineering services to companies needing assistance with their ACF (anisotropic conductive film) hot-bar bonding process. Bonding with a hot-bar (thermode) is an ideal way of making anisotropic conductive film attachment. The best way to begin is by sending us pictures or samples of your products that you wish to have bonded. Then we can make a recommendation of what equipment would be best, and provide price and availability on the equipment you need.

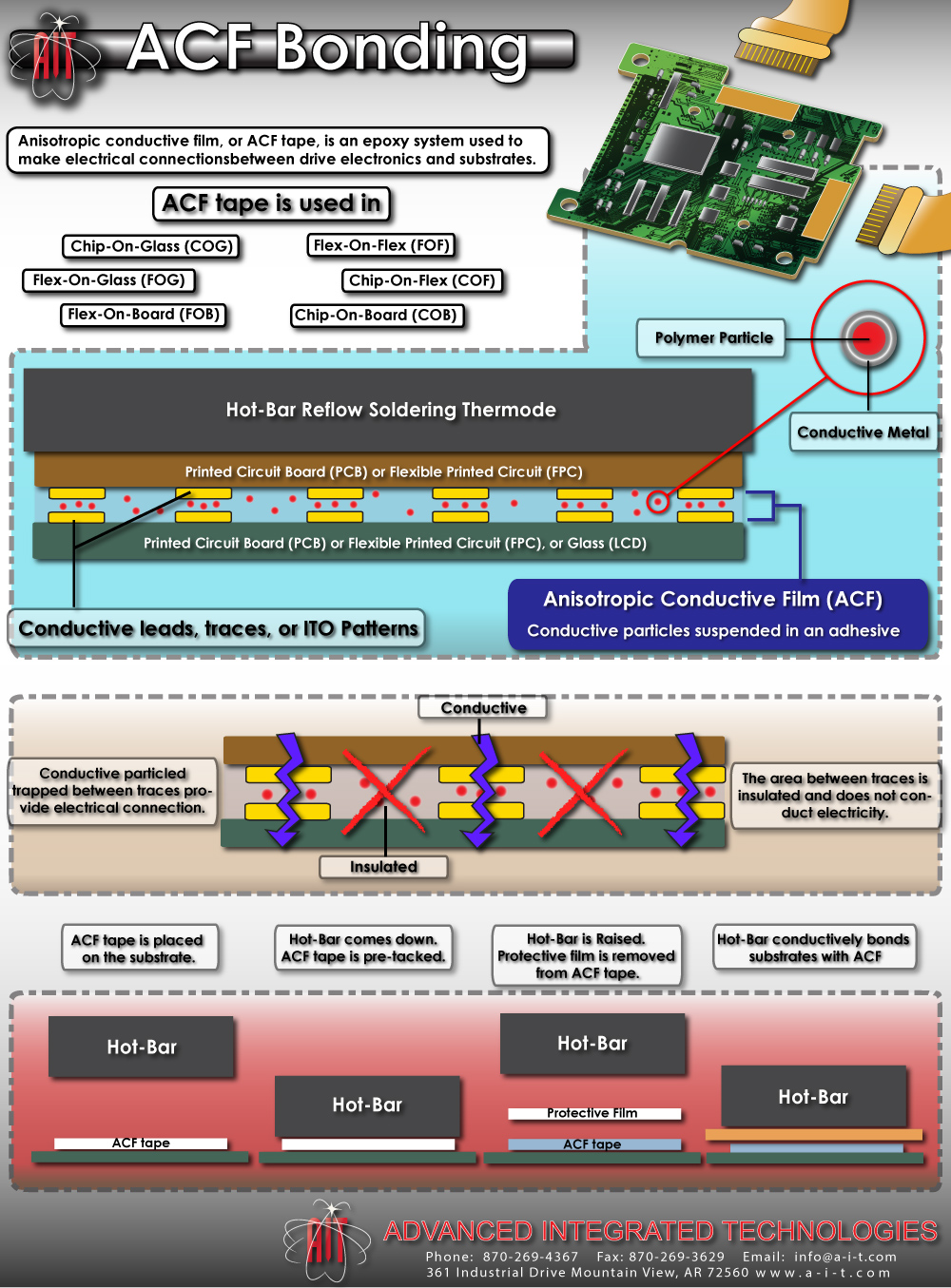

About ACF

(Anisotropic conductive film) or ACF tape is an epoxy system used to make electrical connections between drive electronics and substrates such as chip-on-glass (COG), flex-on-glass (FOG), flex-on-board (FOB), flex-on-flex (FOF), chip-on-flex (COF), chip-on-board (COB), and similar applications.

The ACF Bonding Process

ACF material is a heat bondable adhesive with conductive particules randomly distributed throughout in such a way that when compressed and curred, it is only conductive in the Z axis, and not conductive in X or Y (horizontally), so that insulation value is maintained between traces on a PCB or other component. During the ACF bonding process, heat and pressure are applied via a thermode ( or hot bar) on to the ACF film or other component that is sandwiching the ACF material between the drive and substrate. The conductive particles are compressed between the traces or conductive bumps on the components being joined. The spheres are compressed together contacting the bonding footprints and thus provide electrical contact. As the heat is removed, the conductive particles are trapped into permanent compressed form. The particles are distributed with a minimum chance of electrical shorting in the x-axis and y-axis, other than under the points of compression.

ACF has been used in glass display applications for many years. It has recently become widely used in COF and COB areas. Industries that use this technology most are the mobile phone manufacturing, automotive industry, and LCD production / mobile computers. The source for heat and pressure in ACF bonding is most often a hot bar, or thermode. Hot bar bonding systems are designed to heat the hot bar to a specific temperature using low voltage electricity, which temperature is fed back to the controller via a thermocouple. Tooling is designed to hold the components incorrect orientation and position while the bonding is taking place. The hot bar is then brought into contact with the ACF material over the top of the bonding pad, heated to the bonding temperature, and held for a specified time. This process is what produces the connection between the ACF material and the components. Advanced Integrated Technologies is equipped to assist you with your ACF bonding process. Call us today to put our experience to work for you.

To share this AFC Bonding Infographic, please copy and paste the code below into your website or blog.

<a href="https://www.a-i-t.com/hot-bar-soldering-equipment/acf-bonding"> <img src="https://www.a-i-t.com/images/acf-bonding-infographic.jpg" alt="AFC Bonding"> </a>