AIT Resistance Welding Electrodes

The S-25 series electrode is equivalent to the EMT-187 series electrodes developed by Hughes and later Palomar Products. The hollow shank is designed to accept a heating element. Tips are available in tungsten or molybdenum. Understanding AIT part numbers is very simple. Various dimensions on the drawing are represented by letters, which correspond to values in the part number. The beginning of the part number establishes the electrode series and material, followed by various dimensions. You can request a quote by filling in dimensions below in the custom part number and indicating the quantity you wish to have quoted in the comments section.

Contact the factory for assistance at (870)-269-4367.

Understanding AIT part numbers is very simple. Various dimensions on the drawing are represented by letters, which correspond to values in the part number. The beginning of the part number establishes the electrode series and material, followed by various dimensions. For example, part number S-25-M-A.007B.005C.012D.0015 is a molybdenum electrode with an A dimension of .007 . You can request a quote by filling in dimensions below in the custom part number and indicating the quantity you wish to have quoted in the comments section. Or you can request a quote for a standard part number in the list below by entering a quantity in the box next to the desired part number. Equivalent Hughes part numbers are listed below cross referenced to AIT part numbers.

{sfg:153}

Click image to enlarge.

The S-26 series electrode is designed for use in welding wires. The groove in the tip can capture the wire and provide more surface contact between the electrode and the wire. Understanding AIT part numbers is very simple. Various dimensions on the drawing are represented by letters, which correspond to values in the part number. The beginning of the part number establishes the electrode series and material, followed by various dimensions. You can request a quote by filling in dimensions below in the custom part number and indicating the quantity you wish to have quoted in the comments section.

Contact the factory for assistance at (870)-269-4367.

Understanding AIT part numbers is very simple. Various dimensions on the drawing are represented by letters, which correspond to values in the part number. The beginning of the part number establishes the electrode series and material, followed by various dimensions. For example, part number S-26-M-A.007B.005C.012D.0015 is a molybdenum electrode with an A dimension of .007 . You can request a quote by filling in dimensions below in the custom part number and indicating the quantity you wish to have quoted in the comments section. Or you can request a quote for a standard part number in the list below by entering a quantity in the box next to the desired part number. Equivalent Hughes part numbers are listed below cross referenced to AIT part numbers.

{sfg:145}

Click image to enlarge.

The S-27 series electrode is equivalent to the EL-125 series electrodes developed by Hughes and later Palomar Products. The electrode are primarily used in grip type hand piece welders. Tips are available in class 2 copper, glidcop, copper-tungsten, molybdenum, and tunsten. Understanding AIT part numbers is very simple. Various dimensions on the drawing are represented by letters, which correspond to values in the part number. The beginning of the part number establishes the electrode series and material, followed by various dimensions. You can request a quote by filling in dimensions below in the custom part number and indicating the quantity you wish to have quoted in the comments section.

Contact the factory for assistance at (870)-269-4367.

Understanding AIT part numbers is very simple. Various dimensions on the drawing are represented by letters, which correspond to values in the part number. The beginning of the part number establishes the electrode series and material, followed by various dimensions. For example, part number S-27-M-A.007B.005C.012D.0015 is a molybdenum electrode with an A dimension of .007 . You can request a quote by filling in dimensions below in the custom part number and indicating the quantity you wish to have quoted in the comments section. Or you can request a quote for a standard part number in the list below by entering a quantity in the box next to the desired part number. Equivalent Hughes part numbers are listed below cross referenced to AIT part numbers.

{sfg:146}

Click image to enlarge.

The S-24 was the original DUS TIP developed by Hughes Aircraft. This series is a single ended deep access parrallel gap electrode with an insulator (spacer) that binds the two halves together and establishes the width of the gap. The Hughes DUS TIP used pins and screws to bind the two halves together. This design uses an adhesive insulator which is a much more economical design that works very well. Custom materials are available. Contact the factory for assistance at (870)-269-4367.

Understanding AIT part numbers is very simple. Various dimensions on the drawing are represented by letters, which correspond to values in the part number. The beginning of the part number establishes the electrode series and material, followed by various dimensions. For example, part number S-24-M-A.007B.005C.012D.0015 is a molybdenum electrode with an A dimension of .007 . You can request a quote by filling in dimensions below in the custom part number and indicating the quantity you wish to have quoted in the comments section. Or you can request a quote for a standard part number in the list below by entering a quantity in the box next to the desired part number. Equivalent Hughes part numbers are listed below cross referenced to AIT part numbers.

{sfg:49}

Click image to enlarge.

The S-23 series is a parrallel gap electrode design for use in the Unitek round electrode holders, and functions the same as the Unitek Unitip L series electrodes. Custom materials are also available. Contact the factory for assistance at (870)-269-4367.

{sfg:48}

Click image to enlarge.

The S-22 series is a tweezer electrode made for use in the Unitek THP and PHP. Contact the factory for assistance at (870)-269-4367.

{sfg:47}

Click image to enlarge.

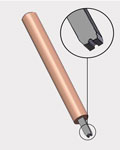

S-21 Round Tip

The S-21 series is a fully customizable spot welding round electrode available in multiple materials. See the drawing for an understanding of the various dimensional values and construction of this electrode. It comes with a .125” or .250” diameter copper body. Glidcop and copper versions are built from one piece, and essentially any A value larger than .025” diameter is acceptable in these two materials. Tip materials of class 11 copper-tungsten, class 13 pure tungsten (W), and molybdenum (M) have the tip pressed into the shank, with standard A values for pressed materials being .062” , .093” , and .125” . Other A values requested in pressed materials will be constructed by inserting a standard A diameter material size, and then resizing the end of the tip. Please note that requesting non-standard A dimensions with class 11 copper-tungsten, class 13 pure tungsten, and molybdenum materials will add additional cost to the base price of the electrode. Adding a –B to the end of the part number makes the tip brazed into the copper shank. Adding a -P to the end of the part number makes the tip pressed into the copper shank with no brazing. Tip sizes with an A value larger than .125 are always brazed onto the copper shank. While brazing the tip material into the shank adds some additional cost to the electrode, we highly recommend using this option, as it produces a superior electrode. An electrode with a pressed tip and no brazing has the potential for the resistance to change due to oxidation of materials at the joint between the tip and shank. This can lead to inconsistent welding results. Custom materials are also available. Contact the factory for assistance at (870)-269-4367.

{sfg:44}

Click image to enlarge.

S-21 Square Tip

{sfg:45}

Click image to enlarge.

S-20

The S-20 series is a parallel gap electrode design for use in the Miyachi Unitek round electrode holders, and functions the same as the Miyachi Unitek Unitip C series electrodes. This electrode is functionally the same as our S-23 series, but more expensive. We advise picking an S-23 design with equivalent tip size if you need this electrode. The S-23 offers better clearance angle and works the same as this S-20 electrode.

Understanding AIT part numbers is very simple. Various dimensions on the drawing are represented by letters, which correspond to values in the part number. The beginning of the part number establishes the electrode series and material, followed by various dimensions. You can request a quote by filling in dimensions below in the custom part number and indicating the quantity you wish to have quoted in the comments section.

{sfg:43}

Click image to enlarge.

S-19

The S-19 series is a round electrode with a flat face and a tapered angle leading up to the tip. See the drawing for an understanding of the various dimensional values and construction of this electrode. It comes with a .125” or .250” diameter copper body. Glidcop and copper versions are built from one piece, and essentially any A value larger than .025” diameter is acceptable in these two materials. Tip materials of class 11 copper-tungsten, class 13 pure tungsten (W), and molybdenum (M) have the tip pressed into the shank, with standard A diameters for pressed materials being .062” , .093” ,and .125”. Other A values requested in pressed materials will be constructed by inserting a standard A diameter material size, and then resizing the end of the tip. This electrode also has an optional tip radius “R” that can be added to the electrode if needed. Leave the R value completely out of the part number if you do not need this clearance angle. Please note that requesting a R radius, as well as using non-standard A dimensions with class 11, class 13, and molybdenum materials will add additional cost to the base price of the electrode. Adding a –B to the end of the part number makes the tip brazed into the copper shank. Adding a -P to the end of the part number makes the tip pressed into the copper shank with no brazing. While brazing the tip material into the shank adds some additional cost to the electrode, we highly recommend using this option, as it produces a superior electrode. An electrode with a pressed tip and no brazing has the potential for the resistance to change due to oxidation of materials at the joint between the tip and shank. This can lead to inconsistent welding results. Custom materials are also available. Contact the factory for assistance at (870)-269-4367.

{sfg:41}

Click image to enlarge.

S-18

The S-18 series is a fully customizable electrode designed with a radius on the tip. Custom materials are also available. Contact the factory for assistance at (870)-269-4367.

Understanding AIT part numbers is very simple. Various dimensions on the drawing are represented by letters, which correspond to values in the part number. The beginning of the part number establishes the electrode series and material, followed by various dimensions. For example, part number S-18-2-A.031B.125C8D1.378 is a copper electrode with an A radius of .031 . You can request a quote by filling in dimensions below in the custom part number and indicating the quantity you wish to have quoted in the comments section. Or you can request a quote for a standard part number in the list below by entering a quantity in the box next to the desired part number. Equivalent Avio part numbers are listed below cross referenced to AIT part numbers.

{sfg:40}

Click image to enlarge.