Spot Welding Machine

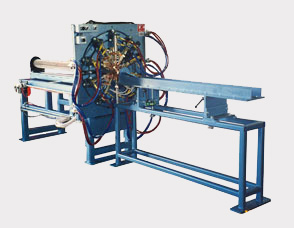

This fully automatic Multi-Head Welder is designed to load, weld and unload Filter Bag Collar’s .

Features:

- 4 to 16 weld guns

- Direct or Series Welding

- Blanchard ground T-slot front plate to allow guns to adjust around center weld die

- Guns are mounted on slotted gun mounts to allow guns to move in-out for various length collars

- Water-cooled weld mandrel has insulated wear plates

- Automatic ring loader and magazine chute

- Controlled part indexer

- Automatic part unloader

Features:

- Feed Reel Station: This station is 10” x 16” x 10” high, its function is to house up to fourteen customer reel spools

- Wire Puller: 1 HP D.C. motor and reducer with regenerative drive and encoder

- Wire Form Station: Is attached to seam welder and has its own regenerative drive motor, reducer, controller and encoder.

- Seam Welder Station: Employs two Janda heavy-duty Timken bearing weld heads, transformer and weld control. Entire secondary is water-cooled including weld transformer, SCR contactor, weld heads (both internal and external), plus four water jets are set to cool seam weld wheels and welded wire.

- Roll Former: This station will also have motor, reducer, regenerative SCR speed control, encoder and guards.

- Cut-Off Table & Die

- Wire Guide System

- Contingent on wire grade machines run at 80 ft. to 140 ft. per minute

JANDA Model GMAW-1-10 Door Mig Seam Welder with Miller Power Supply.

Features:

- Built-in Squeeze timer to ensure electrode pressure is constant before welding

- Dual pressure system with Buck & Weld pressure regulators

- Low Inertia head, plus micro switch to insure electrode has made contact prior to squeeze time

- No adjustable micros and springs that are almost impossible to adjust and vary between welds

- Two stage foot switch – 1st stage for location, 2nd stage in series with contact micro to initiate squeeze timer

- Swivel upper & lower weld adaptors

- Electrode holder moves in-out for electrode alignment

- All components are interfaced

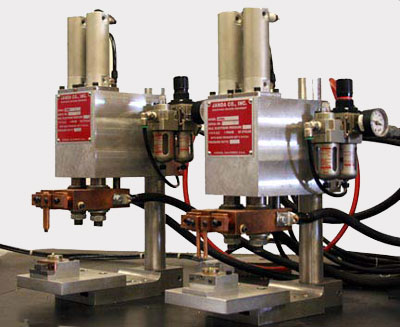

MODEL APM-2

- Dual weld heads operate simultaneously or independently thru selector switch

- Individual air systems for each weld head

- Lower T-slot for tooling

| APM-1 & APM-2 | |

|---|---|

| Weld Pressure | 2 – 36 Lbs |

| Max. Rating | 2 KVA |

| Max. Electrode Stroke | 1″ |

| Depth | 5.75″ |

| Max. Tip Distance | 1″ |

| Electrode Diameter | .250″ |

| Electrode Holder | Offset |

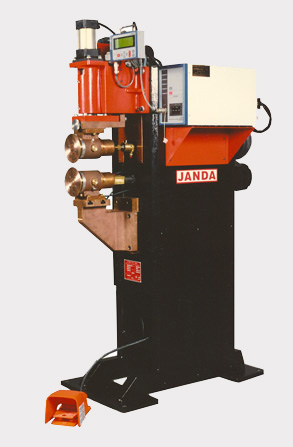

Press Type, Rocker Arm, Seam, Circumferential Seam

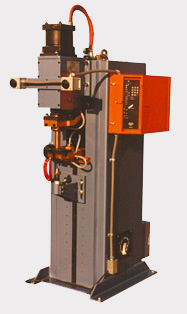

Three Phase Frequency Inverter Bench Type Platten Press

Features:

- Up to 85 KVA

- Up to 20,000 D.C. secondary amps

- 1000 to 1600 hertz control

- Built-in weld checker

- Diaphragm 3″ weld head

- Dual air pressure system

- Adjustable up-down lower knee

- Water-cooled transformer, control & secondary

JANDA’s Gun Welders come complete with specific weld gun to meet your requirements and all components interconnected and ready for installation or installed on an optional Boom Station.

Features:

- Water-cooled weld gun is connected to rotary bail and hanger assembly

- Gun Type Weld Transformer

- Weld Control

- Dual conductor weld cable

- Weld & retraction cylinders, FRL, and weld & retraction valves are all interconnected to weld gun

Optional Boom Station

- 10’ high with 8’ I-Beam that will rotate 180 degrees. Weld transformer and weld control are mounted on upright and interconnected. Reel type balancer is mounted on trolley to allow gun to move in-out. All components are mounted onto Boom station and interconnected.

JANDA offers a complete line of standard T-Welders for operation from 15 to 35 KVA. If your application requires a larger capacity, consult factory for a JANDA Special Welder or Standard Dual Head T-Welder

Features:

- Dual voltage welding transformers

- Transformers are stacked core with water-cooled secondary’s

- Clamp dies and upset electrode force have independent cylinders, solenoid valves, and air regulators

- Class 2 weld dies are water-cooled

- Serrated clamp dies are heat treated

| Model | KVA | Capacity Mild Steel |

|---|---|---|

| T-15 | 15 | 5/16″ Diameter |

| T-25 | 25 | 3/8″ Diameter |

| T-35 | 35 | 11/16″ Diameter |

JANDA offers a complete line of standard Butt Welders for operation from 15 to 35 KVA. If your application requires a larger capacity, consult factory for a JANDA Flash Welder or a Special Welder to meet all of your requirements.

Features:

- Dual voltage welding transformers

- Transformers are stacked core with water-cooled secondary’s

- Clamp dies and upset electrode force have independent cylinders, solenoid valves, and air regulators

- Class 2 weld dies are water-cooled

- Serrated clamp dies are heat treated

| Model | KVA | Capacity Mild Steel |

|---|---|---|

| B-15 | 15 | 5/16″ Diameter |

| B-25 | 25 | 3/8″ Diameter |

| B-35 | 35 | 11/16″ Diameter |

Precision Bench Model Butt Welder

Can be used for arc percussive welding or basic in line with A.C. or capacitor discharge.

*Reduce production time

*Reduce production costs

*Unlimited capabilities

*Economically Priced

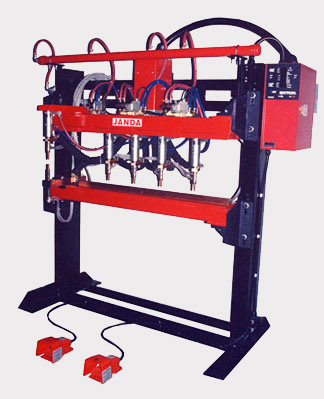

Features:

- Available in 36” to 96” widths

- Up to 12 dual piston weld heads, adjust across face thru T-slot and in-out up to 1 1/2”

- Utilize up to (3) 70, 90, or 120 KVA dual secondary transformers

- Bolt on lower table and upper gun mount

- Adjusts up & down over 12”

Optional Features:

- Series Copper Bar

- Upper gun and lower arm extensions

- Press Type Welder Attachment

- Carriage / Fixture tables

- Table power drive systems

*Inside width – 48″, 60″, 72″, 84″, 96″

| Model | Weld Guns | Controls | Transformers | |

|---|---|---|---|---|

| m(*)-4-90-1C | 4 | 1 | 1 | All guns weld simultaneously |

| m(*)-6-90-1CG m(*)-8-90-1CG m(*)-10-90-1CG m(*)-12-90-1CG |

6 8 10 12 |

1 1 1 1 |

1 1 1 1 |

Cascade guns |

| m(*)-6-90-1C2T m(*)-8-90-1C2T |

6 8 |

1 1 |

2 2 |

Cascade Transformers |

| m(*)-10-90-1C3T m(*)-12-90-1C3T |

10 12 |

1 1 |

3 3 |

Cascade Transformers |

| m(*)-6-90-2C m(*)-8-90-2C |

6 8 |

2 2 |

2 2 |

All guns weld simultaneously |

| m(*)-10-90-3C m(*)-12-90-3C |

10 12 |

3 3 |

3 3 |

All guns weld simultaneously |

1CG: Cascade Guns

Weld guns cascade down and weld in groups of four (or less)

1C(*)T: Cascade Transformers

(*) # of Transformers & SCR Contractors. All weld guns move down and transformers cascade weld on own contractor with head and weld time.

1 Phase power input.

(*) # of controls and Transformers

Simultaneous welding

3 Phase power input

JANDA’s DC Inverter with constant power and current control ensures high quality welds on aluminum alloys and stainless steels.

Features:

- Three phase high frequency inverter power supply operates at 1200 hz with primary and secondary constant current

- Fully rectified DC secondary – virtually no secondary inductive loss

- Built-in weld checker simultaneously monitors current, voltage, power, welding time and detects problems

- Heavy-duty reinforced frame’s withstand heavy pressures required for certifications

- Compact design allows for full three phase power in a single phase frame size

- Upper weld head adjusts left-right

- Lower weld head adjusts left-right thru T-slot & moves up-down up to 6” for different wheel diameters

- Lower or upper head drive with SCR speed control

- Internally water-cooled weld shafts

- Camrol guided ram

Optional

- Tip Dress & Forge , Retraction, Adjustable Weld Stroke, Dual Drive

| Model | Throat Depth | KVA | Max. Amps | Weld Force @ 80 P.S.I. | Capacity Mild Steel | Capacity Aluminum |

|---|---|---|---|---|---|---|

| PTMFS1-40-18 PTMFS1-40-24 |

18 24 |

40 | 14,000 | 800 | 22 GA | |

| PTMFS2-85-18 PTMFS2-85-24 PTMFS2-85-30 |

18 24 30 |

85 | 20,000 | 1,075 | 18 GA | 0.020 0.016 |

| PTMFS3-170-18 PTMFS3-170-24 PTMFS3-170-30 PTMFS3-170-36 |

18 24 30 36 |

170 | 45,000 | 2,800 | 11 GA 12 GA |

0.060 0.050 |

| PTMFS3-250-30 PTMFS3-250-36 PTMFS3-250-42 |

30 36 42 |

250 | 50,000 | 5,000 | 10 GA 11 GA |

0.065 0.060 |