Hot-Bar Reflow Soldering

Providing you with new and used equipment, rentals, thermodes, and support for your hot-bar soldering project.

High quality hot bar soldering machines

Lower prices on equipment and hotbars (thermodes) than other manufacturers

Shorter lead time

Custom solutions and unparalleled customer support

How We Can Help You

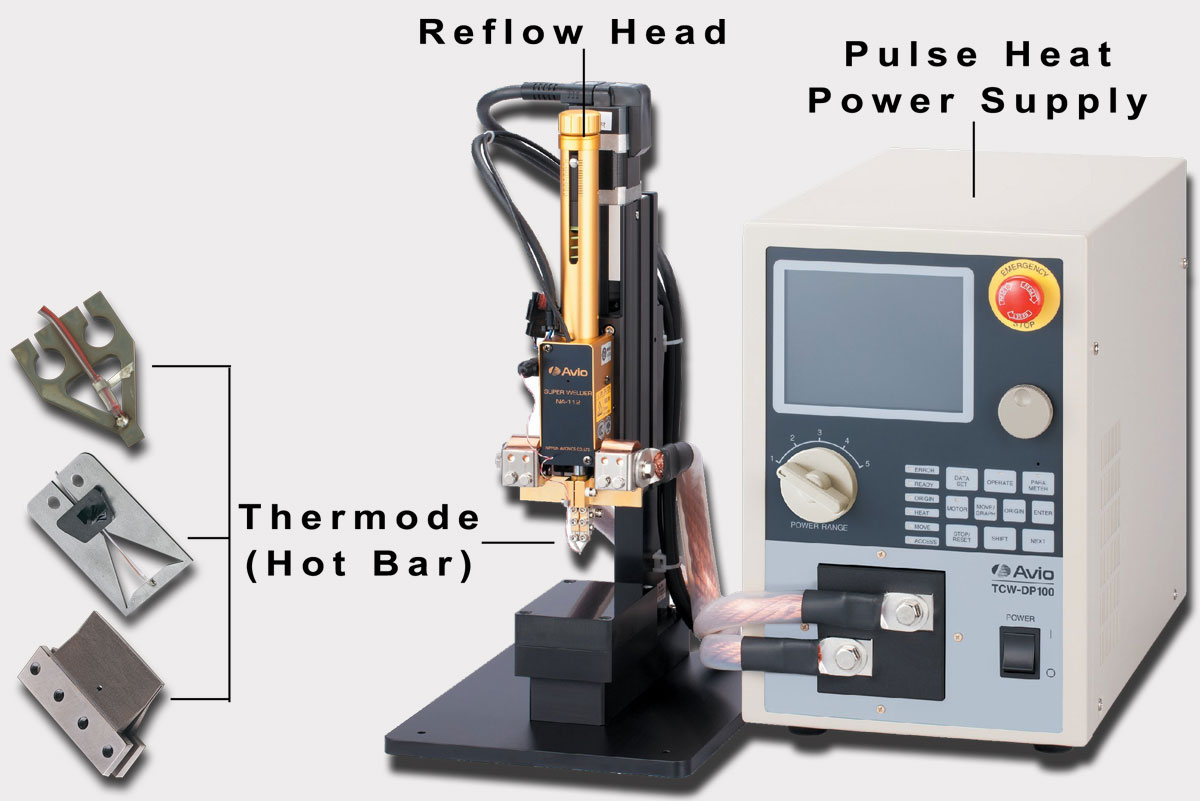

Advanced Integrated Technologies Inc (AIT) sells and provides technical support for new hot bar reflow soldering machines built by Nippon Avionics ( Avio ). We also offer used rental equipment for some customers. If you are exploring the possibility of using hot bar soldering equipment for your soldering or bonding application, we can evaluate your samples products, and provide assistance in determining the correct equipment for your needs. Unless you are already an expert in this field, we strongly advise that you call or email us and discuss your application. There are many factors to consider in choosing the right equipment.

About Us

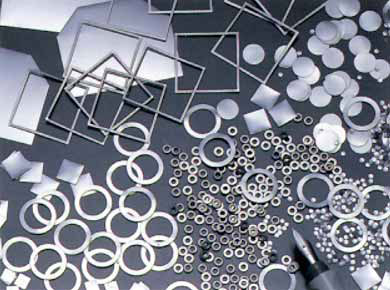

Advanced Integrated Technologies Inc (AIT) is recognized throughout the world as a leading authority on hot-bar soldering equipment, including the manufacturing of hot bars and reflow soldering thermodes. Get the benefit of our 20+ years of experience building hot-bars (thermodes) for Unitek, Hughes, Avio, and many other bonding systems.

Advanced Integrated Technologies Inc ( AIT ) assembles and builds systems, tooling, and thermodes for the hot-bar reflow soldering process. We manufacture reflow soldering thermodes (hot-bars) at prices far below that of the original machine manufacturers. AIT builds tools equivalent to all the Miyachi Unitek thermodes, as well as Nippon Avionics Co., Ltd (Avio), Palomar-Hughes, MacGregor, and Sunstone Engineering. We are the affordable source for thermodes used in all hot bar reflow soldering and ACF bonding applications. If you are trying to cut costs and find affordable thermodes, call us today.

Advanced Integrated Technologies Inc ( AIT ) assembles and builds systems, tooling, and thermodes for the hot-bar reflow soldering process. We manufacture reflow soldering thermodes (hot-bars) at prices far below that of the original machine manufacturers. AIT builds tools equivalent to all the Miyachi Unitek thermodes, as well as Nippon Avionics Co., Ltd (Avio), Palomar-Hughes, MacGregor, and Sunstone Engineering. We are the affordable source for thermodes used in all hot bar reflow soldering and ACF bonding applications. If you are trying to cut costs and find affordable thermodes, call us today.

Reflow Soldering

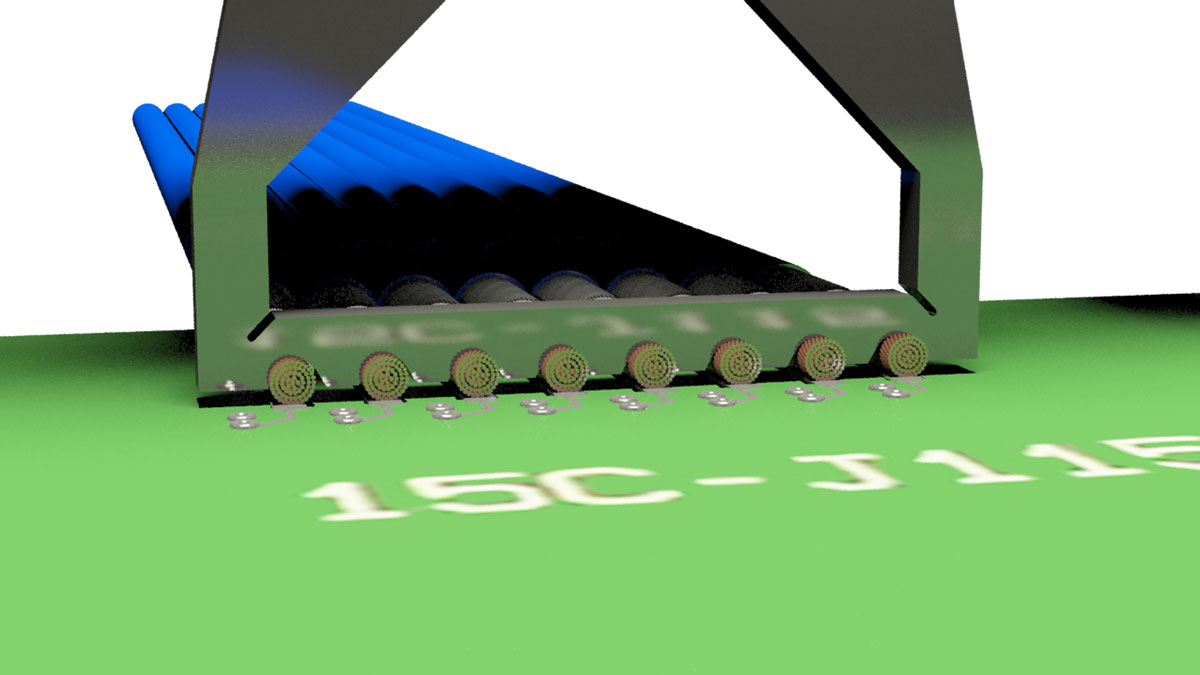

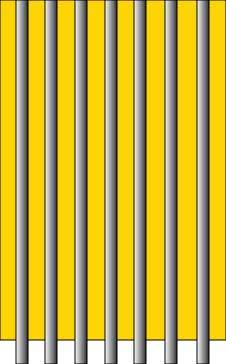

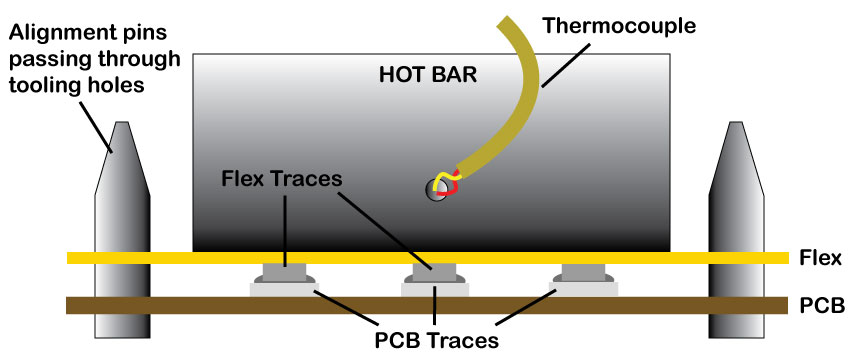

Hot bar reflow soldering is a soldering process where two pre-fluxed solder coated parts are rapidly heated with a thermode to a high enough temperature to cause the solder to flow, and then cooled to re-solidify, forming a bond between the parts. Electrical energy flows through the thermode causing it to heat at the point of highest resistance and melt the solder or adhesive and create the connection. As the electricity flows through the thermode, heat generated is conducted directly to the work piece. Typical hot bar reflow soldering and reflow soldering applications include flexible circuits, ribbon cables, wires, coaxial cables, SMT components, single or dual sided edge connectors, LCD repair and soldering of gold wire.

Hot Bar Reflow Soldering

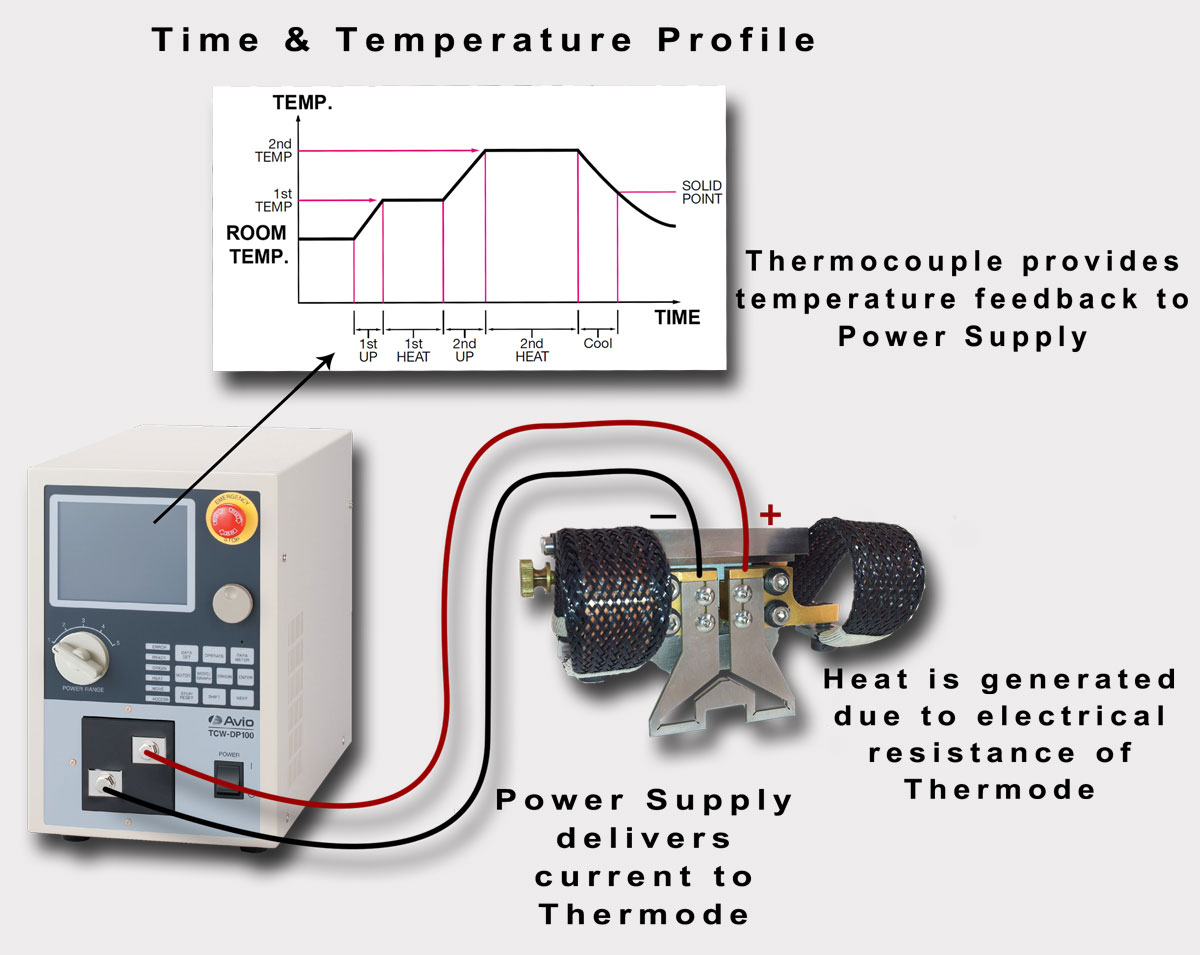

Hot Bar Reflow Soldering is a selective soldering process used to join two solder coated components. During hot bar soldering, a thermode (hot-bar) is heated to a specific temperature by a pulse heat power supply. Temperature is controlled by thermocouple feedback. The thermode is then used to apply pressure and heat over a set time period, squeezing the two solder coated components together. The thermode applies sufficient heat to cause the solder to melt and flow, after which the components are cooled under pressure, thereby creating an electro-mechanical bond between the two components.

The soldering process requires pressure. When a soldering cycle is initiated, the reflow head causes the thermode to travel down into contact with the components to be joined. The amount of down force can be set as desired on the reflow head.

3 ways to apply pressure

AIR

SERVO

MANUAL PEDAL

Selecting Solder Alloys

Solder alloys are selected for the following properties:

•Melting point

•Mechanical characteristics

•Wettability

•Abscence of Lead

About Solder

•Common solder alloys used in electronics manufacturing:

–tin-lead:Sn63Pb37 (Melting Point 183 Celsius)

–tin-silver-copper:SAC305: Sn96.5Ag3Cu0.5 (Melting Point 218 Celsius)

–tin-silver-copper:SAC305: Sn96.5Ag3Cu0.5 (Melting Point 218 Celsius)

•Alternative “lead free” alloys include:

–tin-silverSn96Ag4 (Melting Point 221 Celsius)

–tin-copper-nickelSn100C (Melting Point 227 Celsius)

Physical Forms of Solder

•Rosin Core Wire Solder (various sizes and flux types)

•Pre-Forms (custom manufactured)

•Solder Paste (spherical metal particles suspended in flux)

Eutectic solder increases process predictability

-Melting point of the solder

-Flow (wetting) action behavior

Eutectic solders

–Transitions from solid to liquid at a fixed temperature

–Lower melting point than parent metals

•Example: Sn63Pb37 melts at 183 C

•Example: Sn62Pb36Ag2 melts at 179 C

Flux

- Flux is a chemical agent that assists in the soldering process by removing and preventing oxide formation.

- Flux is a catalyst that does not become part of the final metal composition.

- Flux improves the wetting action of solder by lowering the surface tension of the solder.

- Each flux has an optimum working temperature where it reacts chemically with oxidized metal surfaces

Flux activation or working temperature is an optimum range of temperatures where it chemically reacts with oxidized metal surfaces.

Flux for electronics applications:

- Must be heated to remove oxides

- Relatively “inert” at room temperatures

Electronics Fluxes

Water Soluble

- Most active type of flux

- Residue is corrosive and conductive

- Requires cleaning equipment and hot water treatment

Rosin Activated

- Very active flux

- Requires saponifier (chemical) and hot water to clean

Rosin Mildly Activated

- Promotes good wetting on oxidized surfaces

- Requires saponifier (chemical) and hot water to clean

No Clean

- Least active type of flux

- Reflow process must occur within 5 minutes of application

- Low solids content leaves little residue

- No cleaning required or possible

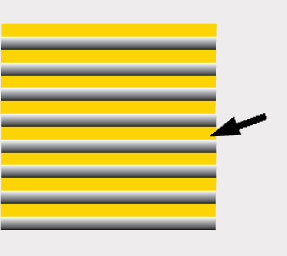

Flex Circuits

- Most common type is polyimide (also known under the trade name of Kapton)

- Two layers of polyimide encapsulate the copper traces(normally 0.5–2oz)

- Copper is Rolled Annealed or Electro-Deposited (most cos teffective and widely used)

- Thickness of copper traces ranges from 0.0007–0.004 inches (18-100microns)

- Operating temperatures ranging from130–200°C (can with stand soldering temperatures up to 300°C for a short time)

- Thickness of the polyimide ranges from 0.001–0.0047inches (25-120microns)

| Type | Advantages | Disadvantages | |||

|

|

Lower thermode temperatures. | Flux contamination on thermode. Leads can be damaged or bent when handled. |

|

Maximum polyimide thickness, the top layer, needs to be .002 inches or 50 microns. Loss (thermal barrier) of 60–80°C per 25 microns thickness |

|

Single Sided | Easy to handle. Minimal flux contamination on thermode. | Higher thermode temperatures due to thermal barrier. |

|

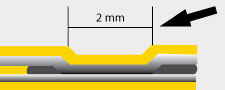

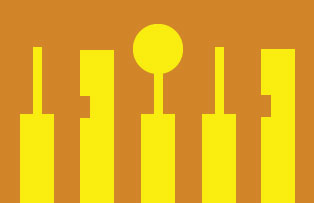

Minimum pitch needs to be.008 inches or 200 microns to avoid short circuits. |

|

Open Windowed | Lower thermode temperatures. | Flux contamination on thermode. Part alignment is critical. |

|

Minimum pad length needs to be .080 inches or 2 mm to allow fillets to form. |

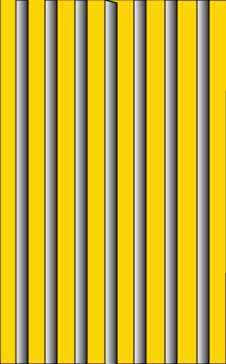

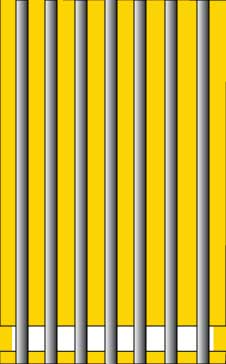

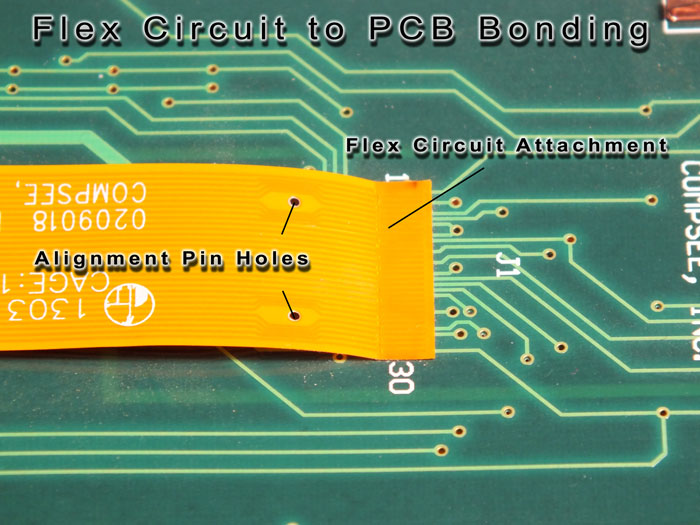

PCB Design

- Width of the PCB traces should be 50% of the pitch to avoid short circuits

- Make PCB traces wider than flex traces to allow solder to flow and fillets to form

- Tooling holes in PCB and Flex allow easy alignment of traces

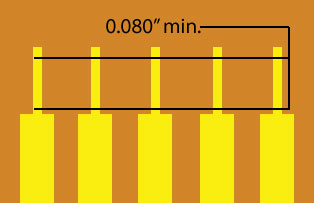

- Provide room for thermode to overhang both ends of pad area by 0.040”(1mm)

PROBLEM

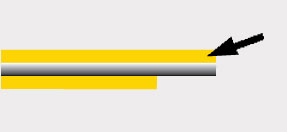

Differences in heat sinking from pad to pad can cause uneven heating:

Unequal trace area and plated through holes act as a heat sink, causing uneven heat distribution.

SOLUTION

Equal trace sizes (mass) leads to equal heating and better solder joint quality. Minimum .08" wide solder area is recommended.

THERMODE TYPES

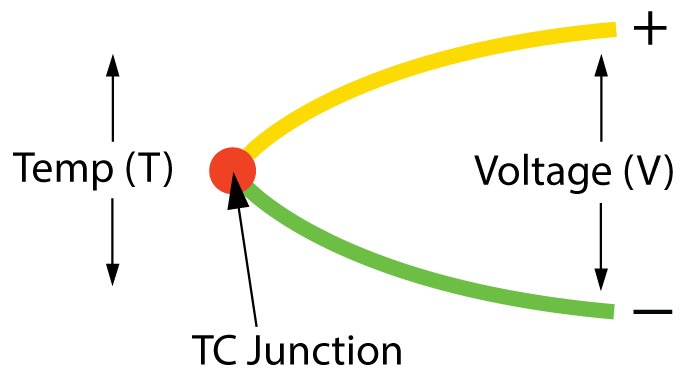

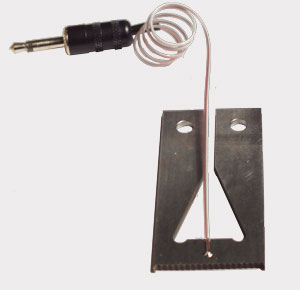

Thermocouple Function

A thermocouple is two wires of dissimilar alloy that are joined into a ball at one end, and open at the other end. Typically the open end is fitted with a plug and the ball end is welded to the thermode near the tip. As thermode temperature increases, so does the voltage across the two wires. This changing voltage feeds back a temperature reading, telling the power supply the temperature of the thermode face. This is what allows the power supply to accurately control the thermode temperature.

Thermocouple Types

Type E: Chromel-Constantan

Type J: Iron-Constantan

Type K: Chromel-Alumel

THERMODE MAINTENANCE

- Routinely remove flux and polyimide residue from thermode using Acetone or Isopropyl Alcohol.

- Resurface thermode face with 600 grit silicon carbide paper on flat surface at low force or grinding wheel if sufficient material is present.

- Improper maintenance in cleaning and resurfacing can result in damaged thermovouples and unlevel thermode faces.

- Use interlayer to reduce contamination of the thermode.

- Automatic Kapton feeder can auto-advance between bonds.

- Permacel P-440 Tape can be applied to thermode face and routinely changed.

SOLDERING PROCESS

- A Thermode is used to apply heat and pressure over a specific time/temperature profile. Temperature feedback is provided via thermocouple.

- Solder needs to be heated to at least 40 degrees Celsius above melting point for about 2-3 seconds to provide the best wetting and flow.

- Heat is produced by passing an electrical current through a thermode which is resistive.

- The force applied transfers the heat to the part and the solder.

- Flux is used to remove and prevent oxide formation.