About Pulse Heat Units

Outline of Pulse Heat Units

Pulse heat units from Nippon Avionics Co., Ltd. have been used over the years for various applications, including soldering in manufacturing of electronic equipment or electronic components, ACF bonding, plastic welding, and thermo-compression bonding.

In the recent years, improvement of both the function and the performance of mobile devices and other electronic equipment are being accelerated. While the parts are getting smaller and higher in performance, technology to mount parts in high density is becoming very important. Among other things, soldering, which is the key technology in parts manufacturing and assembly, is expected to cope with fine pattern and high reliability.

We are offering suitable micro-joining solutions in a timely manner to satisfy the needs of the customer in the manufacturing industry where technical innovation is remarkable.

What is Pulse Heat?

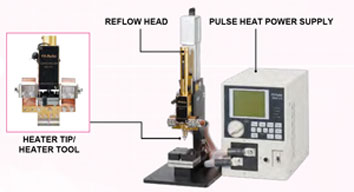

Pulse heat units are equipment used for soldering of electric components or welding of plastic components. It consists of a reflow head, which holds down the component and applies the force, and a pulse heat power supply, which flows the electic current.

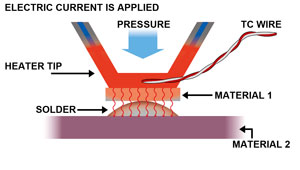

Pulse heat is an instantaneous heating method whereby heating is effected only when melting the solder or the plastic. Solder or plastic is melted by the resistance heat generated by flowing electric current to a heater tip/ heater tool made of metal. Once the material is melted, electric current is stopped and cooled.

Because the object is held down with pressure until it is solidified, there is no lifting or shifting of parts, and, as a result, highly reliable joining can be achieved.

Basic Configuration of a Pulse Heat Unit and Role of Each Part

- Pulse Heat Power Supply: Electric current is flown to the heater tip or heater tool.

- Reflow Head: The object to be joined is held down and force is applied. The applied force is adjusted by a spring.

- Heater Tip & Heater Tool: This is the part which becomes hot by resistance heating. The one with a relatively small area is called "heater tip" and a larger area is called "heater tool".

Pulse Heat Unit Model

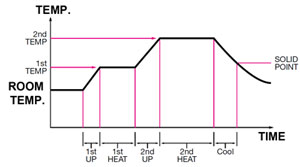

Temperature Profile

| System Head Basic Configuration and Components | |||||

|

|

|

|

|

|

|

|

|

|

||

|

|

|

|

||