Pulse Heat

This slideshow is intended to help the customer choose the appropriate 3M™ Anisotropic Conductive Film (ACF) adhesive product for the job. The data included in this

graphic compare the important physical properties of the products. This product selection guide is to be used to look at the variety of products available and decide on the proper ACF (or ACFs) to each application. In the end it's best to test the application using the particular AFC product. 3M provides a variety of high-performance anisotropic conductive film adhesive products used to mechanically and electrically connect flex circuits and other components to a variety of substrates. These reliable, technologies can replace soldering and mechanical fasteners in many applications, helping to hasten assembly time and lessen space requirements.

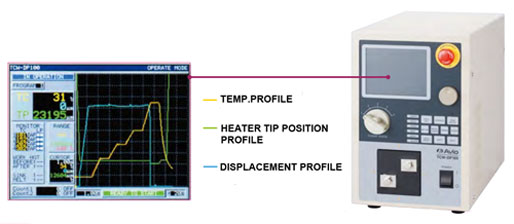

Ultimate Pulse Heat Controller with Concurrency Control of Temperature and Displacement!

TCW-DP100

- High Precision Displacement Control: Overtravelling amount is controlled by feedback of displacement amount in 1μm resolution, and uniform melting amount can be realized.

- Wide Variety of Monitoring Functions (Temperature, Displacement)

- Digital Temperature Control: High speed and highly accurate temperature control is realized by the digital PID control method, making the unit suitable for fine wires and micro-miniature works.

- Release Function: After heating, the solder thickness between the works can be secured.

- Four Stage Heating: Various temperature profiles are realized to cope with the diversified applications

- Built-in Motor Control Function

- User Interface: RS-232C&I/O is standard equipped making the unit easy to interface with the external equipment such as the case of incorporating in an automated system.

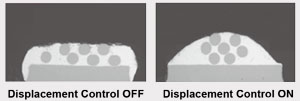

Melting Amounts Control

Micro Co-axial Cable

- No Spread Wire (Damage Reduction)

- No Solder Bridge

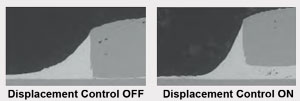

Joining Gap Control

Solar Panel Module

- Enhancement of Joining Strength

- Reduction of Residual Stress

*Reflow head motor drive unitl Model NA-201P is required for use with Model TCW-DP100.*

| Features | TCW-DP100 |

| Heating Temperature |

Room temp~600°C in 1°C step, E type/ J type (option) Room temp~900°C, K type (option) |

| Heating Time | 0.00-99.99 seconds |

| Rated Capacity | 750 VA, 50% duty cycle |

| Heating Steps | 4 Steps |

| Monitor | Sink Amount, Temperature, Work Height |

| Motor Resolution | 1 μm/pulse |

| Displacement Resolution | 1μm |

| Interface | RS-232C, I/O |

| Transformer | Built-In |

| Tap Voltage | 0.88 V, 1.24 V, 1.75 V, 2.47 V, 3.5 V |

| Power Source | AC 200-240 V±10%, 1Φ, 50/60 Hz, 15 A |

| Dimension (mm) | 220x400x320 |

| Weight | 23kg |

Providing you with new and used equipment, rentals, thermodes, and support for your hot-bar soldering project.

Click Here for Hot-Bar Reflow Soldering Equipment.

![]() High quality hot bar soldering machines

High quality hot bar soldering machines

![]() Lower prices on equipment and hotbars (thermodes) than other manufacturers

Lower prices on equipment and hotbars (thermodes) than other manufacturers

![]() Shorter lead time

Shorter lead time

![]() Custom solutions and unparalleled customer support

Custom solutions and unparalleled customer support

How We Can Help You

Advanced Integrated Technologies Inc (AIT) sells and provides technical support for new hot bar reflow soldering machines built by Nippon Avionics ( Avio ). We also offer used rental equipment for some customers. If you are exploring the possibility of using hot bar soldering equipment for your soldering or bonding application, we can evaluate your samples products, and provide assistance in determining the correct equipment for your needs. Unless you are already an expert in this field, we strongly advise that you call or email us and discuss your application. There are many factors to consider in choosing the right equipment.

About Us

Advanced Integrated Technologies Inc (AIT) is recognized throughout the world as a leading authority on hot-bar soldering equipment, including the manufacturing of hot bars and reflow soldering thermodes. Get the benefit of our 20+ years of experience building hot-bars (thermodes) for Unitek, Hughes, Avio, and many other bonding systems.

Advanced Integrated Technologies Inc ( AIT ) assembles and builds systems, tooling, and thermodes for the hot-bar reflow soldering process. We manufacture reflow soldering thermodes (hot-bars) at prices far below that of the original machine manufacturers. AIT builds tools equivalent to all the Miyachi Unitek thermodes, as well as Nippon Avionics Co., Ltd (Avio), Palomar-Hughes, MacGregor, and Sunstone Engineering. We are the affordable source for thermodes used in all hot bar reflow soldering and ACF bonding applications. If you are trying to cut costs and find affordable thermodes, call us today.

Reflow Soldering

Hot bar reflow soldering is a soldering process where two pre-fluxed solder coated parts are rapidly heated with a thermode to a high enough temperature to cause the solder to flow, and then cooled to re-solidify, forming a bond between the parts. Electrical energy flows through the thermode causing it to heat at the point of highest resistance and melt the solder or adhesive and create the connection. As the electricity flows through the thermode, heat generated is conducted directly to the work piece. Typical hot bar reflow soldering and reflow soldering applications include flexible circuits, ribbon cables, wires, coaxial cables, SMT components, single or dual sided edge connectors, LCD repair and soldering of gold wire.