Uncategorised

Call us today at 1-888-304-4367

![]() High quality hot bar bonding machines

High quality hot bar bonding machines

![]() Lower prices on equipment and hotbars (thermodes) than other manufacturers

Lower prices on equipment and hotbars (thermodes) than other manufacturers

![]() Shorter lead time

Shorter lead time

![]() Custom solutions and unparalleled customer support

Custom solutions and unparalleled customer support

Pulse Heat Hot-Bar Soldering

ACF Bonding

Advanced Integrated Technologies Inc ( AIT ) assembles and builds systems, tooling, and thermodes for the hot-bar bonding process. We manufacture hot bar bonding thermodes at prices far below that of the original machine manufacturers. AIT can take your bonding application and source and assemble a used hot-bar bonding system complete and ready to go at a price far below that of a new system. We build tools for all bonding systems including machines made by Miyachi Unitek, Nippon Avionics Co., Ltd (Avio), Palomar-Hughes, MacGregor, and Sunstone Engineering. We are the economical source for thermodes used in all bonding applications. If you don’t see what you’re looking for on our website, call us today. We can build anything you need at very affordable prices.

Hot bar bonding is a general category which applies to conductive adhesive bonding, hot bar reflow soldering, heat staking, and heat seal bonding. Hot bar bonding is done using a 'thermode' which is rapidly heated and cooled for making each connection. The electrical resistance of the thermode produces the heat necessary to melt the solder or adhesive and create the connection. As the electricity flows through the thermode, the heat generated is conducted directly to the workpiece.

Conductive adhesive bonding is a technique for attaching PCBs to displays with conductive adhesive and flex foils. Hot Bar Reflow Soldering is a selective soldering process where two solder or adhesive coated parts are heated to a high enough temperature to cause the solder to flow and re-solidify, forming a permanent bond between the parts. Heat Staking is an assembly process where a piece protruding from one part is fit into a hole in a second part. The piece is then deformed through the application of heat and force (the thermode), forming a head which locks the two pieces together. All of these processes fall within the larger category of hot bar bonding.

Advanced Integrated Technologies Inc ( AIT ) has over two decades of experience manufacturing thermodes for hot bar bonding applications at very affordable prices. We manufacture our own versions of the 17TD three dimensional thermode, 17F Multiple Lead Fold-up Thermode, 17BW Multiple Lead Wide Blade Thermode, 17B Multiple Lead Blade Thermode, as well as all other thermodes available on the market today. Over fifty percent of our business is custom thermode work. We are usually able to build custom thermodes at prices even far below the standard thermode prices of machine manufacturers. Many of the designs in use today were originally built and refined by Advanced Integrated Technologies (AIT). Our extensive experience in this field has made us the industry leader in consumable thermode manufacturing. If you are tired of paying high prices for bonding thermodes, call us today and request a quote. No matter what application you have, we can provide the tools you need at a price you can afford.

AIT provides the machines and technical support for your Micro Resistance Welding Project.

Click Here for Micro Resistance Welding Equipment.

![]() High quality micro-resistance welding machines

High quality micro-resistance welding machines

![]() Lower prices on equipment and electrodes than other manufacturers

Lower prices on equipment and electrodes than other manufacturers

![]() Shorter lead time

Shorter lead time

![]() Custom solutions and unparalleled customer support

Custom solutions and unparalleled customer support

How We Can Help You

Advanced Integrated Technologies ( AIT ) is a provider of micro resistance welders and technical support to companies all over the world. We can evaluate your weld samples, offer free test welds, and specify the optimum equipment for your micro welding project. We also build quality, low cost micro tip electrodes designed to fit any brand of welder you may have. Submit a contact form or call us today for assistance.

About Micro Resistance Spot Welding

Most spot welding fits into one of three categories. Large scale such as that used in the automotive industry involves welding mostly steel and stainless steel, in the thickness range of .016” to .062” thick. Moving down to small scale spot welding, we find the above mentioned materials plus various alloys like molybdenum, tungsten, inconnel, and nichrome in the range of .005” to .020” thickness. The micro scale of spot welding is the smallest, utilized in high tech industries like electronics, medical, bio implant, and telecommunications devices, with a material range of .0005” to .005” thickness.

Several types of welders are capable of micro welding, but the transistor type such as the Avio MCW-700 and MCW-750 are the best for super fine wires and sensitive micro components. The MCW transistor series welders accomplish consistent and precise welding by a high speed linear control, with three control modes: constant current, constant voltage, or constant power. Capacitor discharge and inverter type welders can also be used for somewhat less sensitive micro welding applications.

Micro resistance welding applications require very small and precisely built electrodes. Advanced Integrated Technologies ( AIT ) is the industry leading manufacturer of micro electrodes for all makes of welders including Palomar/Hughes, Unitek, Avio, MacGregor, and Sunstone Engineering. Our high tech manufacturing processes help us to build very high quality low cost electrodes. We offer both parallel gap and single point welding electrodes, in all RWMA materials. Our standard product line of welding electrodes covers the vast majority of applications. AIT also builds a wide range of custom electrode designs for many of our customers. If you need micro resistance welding electrodes, call us today and see how Advanced Integrated Technologies ( AIT ) can help you.

25 years EDM machining experience. Punches, Dies, Medical Devices, Micro Tools, etc.

- Fair prices. Fast delivery.

- Wire EDM up to 14" x 10" x 9".

- Wire EDM wire sizes from .002" to .012" diameter.

- CNC Sinker (RAM).

- Micro holes down to .0017" diameter.

- Our customer service is unsurpassed.

- Complete inspection department.

Save money while getting the benefit of quick turn around and decades of experience. Request a quote from us today!

Advanced Integrated Technologies Inc ( AIT ) offers custom micro EDM services (Electrical Discharge Machining) in both sinker (RAM) EDM format and wire EDM format to customers all over the world. We utilize EDM machines by Agie, Fanuc, Hansvedt, and Pacific Controls. Our Agie Evolution 2 SF+F wire machines are capable of running tungsten wire as small as .002” diameter and machining to a fine finish of 4.4 RMS micro inches (0.1 Ra micrometers). Utilizing 13 wire and 4 sinker EDM machines, we are one of the largest EDM services facilities in the mid south. Our sinker EDM machines are CNC path controlled, offering us great flexibility in the complexity of work we can accomplish. If you need micro EDM machining, AIT can do it. Call or email us today.

AIT’s is fully capable of doing low volume prototype micro EDM work, as well as standard wire EDM work. But we also welcome long production runs numbering in the tens of thousands. Many of our customers seek our input on how to design their products for manufacturability. By working with the customer, and applying our knowledge of manufacturing and wire EDM processes, we can often help engineers design a product that functions well, looks good, and is less expensive to build. This has helped many of our customers be more competitive in the market place.

Much of our wire EDM services involve micro machining and small parts. We have built small parts for companies such as Baxter Laboratories, Boeing, Raytheon, and Panasonic. We serve all machining industries including medical, energy, electronics, and architectural. Many of our customers have found AIT while searching for a wire EDM services provider to machine complicated and high tolerance products. Our reputation has been our single greatest asset in the market place. At AIT we prefer to focus our efforts on projects that fit our core strengths, and on companies looking for a long term dependable relationship.

Our micro EDM services are complemented by a climate controlled inspection department with both CMM measuring technology, and optical gauging capability. We have built our reputation around consistency and accuracy. Each project we accept is carefully reviewed for customer requirements and expectations, and an inspection plan is developed to insure we meet all requirements. Whatever EDM services you require, rest assured that AIT has the experience and capability to exceed your expectations.

|

|

Why use AIT for your CNC Machining Needs?

- 35 years machining experience.

- Fair prices. Fast delivery.

- CNC milling up to 50" x 20" x 25".

- 5 axis CNC turning up to 13" diameter x 20" long.

- Wire EDM up to 14" x 10" x 9".

- Wire EDM wire sizes from .002" to .012" diameter.

- Our customer service is unsurpassed.

- Complete inspection department.

|

|

Advanced Integrated Technologies Inc. ( AIT ) offers precision machining services to customers all over the world. We are capable of prototype machining of single pieces as well as production runs numbering in the millions of pieces. The best way to see what AIT can do for you is to call or email us today and let us

look at the pieces you need built. We can quickly tell if your designs are a good fit for our equipment and we can provide a price and lead time quote in a timely manner.

AIT has been providing precision machining services to companies all over the world for more than thirty years now. Our customers include such recognizable names as Hitachi, Panasonic, Raytheon, Boeing, and many others. When you outsource your machining to AIT, you are getting the benefit of decades of combined machining experience and expertise. You will experience unparalleled customer support.

AIT has 3 machining divisions. Our manual machining area is where we build the simpler and low quantity designs, tooling, and various other items. This is the smallest area of our facility. Our EDM department features 13 wire EDM machines and 4 Sinker EDM machines. EDM machine is one of our specialties. Our third division is our CNC machining department. We feature 3 and 4 axis CNC milling capability as well as 5 axis CNC lathe turning with integrated milling capability. Integrated milling and turn allows us to produce parts complete in one machine that require both milled and lathe turned operations.

At AIT, we do not limit our scope to specific industries. We machine for all industries including medical, architectural, energy, electronics, and aerospace. Our precision machining services are capable of turning up to eleven inches in diameter, but we focus most of our work around products less than twenty pounds in weight. AIT can machine all the standard alloys used in manufacturing, but we find most of our work involves stainless steel and aluminum alloys. Most of our customers that fit within our core manufacturing strengths develop a long term relationship with AIT. We prefer to focus our effort on customers looking for precision machining services from a supplier that is dependable and trustworthy. This allows us to develop long term working relationship with our customers, which proves beneficial to all parties involved.

Our precision machining services are complemented by a quality control system that insures no product leaves our plant unless it conforms to the customers’ expectations. We offer climate controlled Swiss CMM inspection as well as optical measuring capability utilizing Smart Scope technology. We pride ourselves in consistency and accuracy. We develop and deploy an inspection plan for all production runs. Rest assured that AIT can and will produce your products accurately. At AIT we are pleased to offer machining services that exceed customers’ expectations.

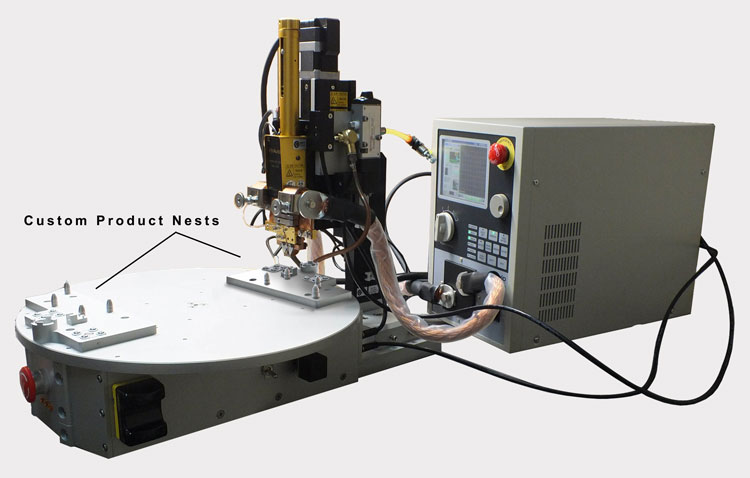

Two-Position Rotary Indexer

Indexer with two product nests that reduces cycle time by 50%

Two-Position Rotary Indexer

IND-2-R1

The 2-position indexer can be used with any resistance welding or hot bar soldering system to decrease cycle time by allowing the operator to load and unload products on the front position while the machine is welding/soldering on the back position. This indexer is very simple in design and effective for increasing output. The 2-position rotary indexer is designed with reliability in mind, but it's also designed to make replacing worn parts very simple and quick. Rotary motion is accomplished by use of a stepper motor that drives the rotary table to hard stops at the clockwise and counter-clockwise limits of travel. This is a very cost effective solution for getting more utilization from your welding or hot bar soldering machine.

- High Speed: Indexer takes approximately 1 second to rotate 180 degrees.

- Safe Operation: Utilizes a clutch that makes the rotation safe for operators hands.

- High Reliability: Designed and built for simple and repeatable operation.

Features |

Two-Position Rotary Indexer |

| Cycle Time |

Approximately 1 second |

| System Voltage |

24 Volt |

| Input Voltage Requirement |

110V |

| Size | 16 inch Diameter Table |

| Space Requirement |

24" wide x 42" deep including Avio power supply |

TCW-315 Hot Bar Soldering Power Supply

The Best Seller Power Supply Unit Suitable for Soldering, Thermo-Compression Bonding and Heat-Fusing!

Pulse Heat Power Supply

General Purpose Type

TCW-315

- High Reliability Joining: Becuause heating and cooling take place while the pressure is being applied, the work position will not be shifted during joining.

- Variable Temperature Profile: Because the heating is local and instantaneous, thermal impact to the peripheral components is restrained.

- High Reprodicibility: Digital PID control enables good reproducitbility of temperature and time. As a result, no skill of the operator is required.

- Pb Free Compatible: Pb free solder is accomodated by setting to high temperature and long heating time.

- User Interface: RS-232C&I/O is standard equipped, making the unit easy to be connected to external equipment such as incorporationg into an automated system.

- Ample Monitoring Functions: Temperature Monitoring: Upper and Lower limit (average peak), Profile Detection Error: Over-Heat, Thermocouple Disconnection, etc.

- Other Standard Functions: Number of stored settings: 15, Head vertical and cooling air control signal, Auxiliary thermocouple input, Counter function.

Features |

TCW-315 |

| Heating Temp. |

Room temp~600°C/1°C step E, J-type Room temp~900°C K-type (Option) |

| Heating Time | 000-999(x100ms, x10ms) |

| Rating Power | 750VA |

| Transformer | Built-In |

| Tap Voltage | 0.88 V, 1.24 V, 1.75 V, 2.47 V, 3.5 V |

| Power Source | 1Φ, AC200-230V±10%, (AC100-115V: option) |

| Dimensions(mm) |

200x320x283 |

| Weight | 19.5kg |

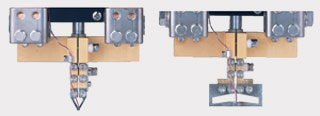

Reflow Head

Select a head having a force suitable to the object to be joined and suitable to the heater tip/heater tool to be used.

Heater Tip/Heater Tool

Select the size and shape suitable to the object to be joined. If necessary, it can be machined for custom shape. A material to which the solder will not stick, easy to heat, and with a high resistance value is used.

Advanced Integrated Technologies is an equipment provider for micro, small, and large spot welding machines and electrodes, as well as ACF bonding and hot-bar soldering equipment. AIT also proivdes wire EDM and CNC machining services. Contact us today for assistance with your next project.