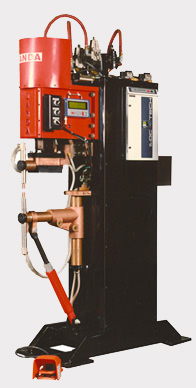

Spot Welding Machine

JANDA offers the most extensive standard line of Seam Welders available. Rocker Arm, Press Type Circumferential, Press Type Longitudinal – Single Phase , Three Phase, AC, DC and Frequency Inverter

Features:

- Internally water-cooled weld heads

- Lower weld head moves in-out thru key

- Lower weld knee moves up-down to accommodate up to two 8” wheels or down to 6” upper and 1 1/2” lower wheel

- Dual pressure air system

- Power driven upper head thru D.C. clutch / brake and adjustable speed control

- Solid state weld control with continuous and roll-spot function

- Two stage foot switch and eight point tap switch

Today’s “State of the Art” DC Inverter with constant power and current control ensures high quality welds on aluminum alloys and stainless steels.

Features:

- Three phase high frequency inverter power supply operates at 1000 hz with primary and secondary constant current

- Fully rectified DC secondary – virtually no secondary inductive loss

- Controls incorporate Constant Current feedback to ensure exceptional reliability and the highest quality welding

- Built-in weld checker simultaneously monitors current, voltage, power, welding time and detects problems

- Heavy-duty reinforced frame’s withstand heavy pressures required for certifications

- Compact design allows for full three phase power in a single phase frame size

- Diaphragm weld head for rapid follow up on forging aluminum alloys

- Low Friction camrol guided ram

- JIC Dual air system

- Swivel Type lower casting with barrel lock

- Adjustable in-out upper & lower arms

Optional

- Retraction

- Adjustable weld stroke

- Tip Dress & Forge

| Model | Throat Depth | KVA | Max. Amps | Weld Force @ 100 P.S.I. | Capacity Mild Steel | Capacity Aluminum |

|---|---|---|---|---|---|---|

| PMF1-40-18 PMF1-40-30 |

18 30 |

40 | 14,000 | 800 | 14 GA | |

| PFM2-85-18 PFM2-85-36 |

18 36 |

85 | 28,000 | 1,075 | 0.120 | 0.070 |

| PFM3-170-18 PFM3-170-36 |

18 36 |

170 | 50,000 | 1,900 | 0.156 | 0.125 |

JANDA’s High-production Press Type welders are available in 20 to 250 KVA single phase and 75 to 500 KVA three phase.

Features:

- Heavy-duty steel frame

- Stacked core transformers

- Dual voltage on 20, 30, & 40 KVA

- Water-cooled transformer, column & upper adaptor

- Swivel type lower casting

- Barrel lock arm & column

- J.I.C. Standard air cylinders

- Water-cooled ejector type electrode holders

- Retraction

- Adjustable weld stroke

- Optional Tip Dress & Forge

| Model | Throat Depth | KVA | Electrode Force @ 80 P.S.I. | Max. Amps | Capacity Mild Steel | Capacity Aluminum |

|---|---|---|---|---|---|---|

| PT1-30-18 PT1-30-24 |

18 24 |

30 | 610 | 17,000 | 14 GA | |

| PT1-40-18 PT1-40-24 |

18 24 |

40 | 700 | 21,000 | 12 GA | 0.020 |

| PT2-50-18 PT2-50-24 |

18 24 |

50 | 1,075 | 26,000 | 0.12 | 0.030 |

| PT2-75-18 PT2-75-24 |

18 24 |

75 | 1,650 | 30,000 | 10 GA | 0.045 |

| PT2-100-18 PT2-100-24 PT2-100-30 |

18 24 30 |

100 | 1,650 2,300 |

37,000 40,000 |

8 GA | 0.055 0.060 |

| PT3-150-24 PT3-150-30 |

18 24 |

150 | 3,150 | 48,000 | 6 GA | 0.090 0.080 |

| PT3-200-18 PT3-200-24 PT3-200-30 |

18 24 30 |

200 | 4,100 5,000 |

56,000 60,000 |

1/4″ 5/16″ |

0.125 0.110 0.090 |

JANDA’s DC Inverter with constant power and current control ensures high quality welds on aluminum alloys and stainless steels.

Features:

- Three phase high frequency inverter power supply operates at 1000 hz with primary and secondary constant current

- Fully rectified DC secondary – virtually no secondary inductive loss

- Controls incorporate Constant Current feedback to ensure exceptional reliability and the highest quality welding

- Built-in weld checker simultaneously monitors current, voltage, power, welding time and detects problems

- Remote programming unit displays 15 functions including trouble data and error codes

- Heavy-duty reinforced frame’s withstand heavy pressures required for certifications

- Compact design allows for full three phase power in a single phase frame size

- Retraction

| Model | Throat Depth | KVA | Secondary Amps | Capacity Mild Steel | Capacity Aluminum |

|---|---|---|---|---|---|

| R2MF-40-18 R2MF-40-24 R2MF-40-30 |

18 24 30 |

40 | 15,000 | .078 TO .078 | |

| R2MF-85-18 R2MF-85-24 R2MF-85-30 R2MF-85-36 |

18 24 30 36 |

85 | 28,000 | .125 TO .125 | .065 TO .065 |

| R3MF-170-24 R3MF-170-30 R3MF-170-36 |

24 30 36 |

170 | 50,000 | 3/16 TO 3 1/16 | .125 TO .125 |

JANDA’s SERIES 300 Rocker Arm Spot Welders offer great versatility for a wide variety of spot welding applications, satisfying all the requirements of light-medium duty industrial applications

Features:

- JANDA J400 Automatic solid state control with (3) 60 cycle timed functions:

- Squeeze – Weld Hold – Off Time – Repeat/Non-Repeat – Weld/No Weld switches

- 180 amp SCR contactor with 15% to 100% heat control

- Stacked-core dual voltage 220/440 water-cooled transformer

- Two stage foot switch

- Laminated Copper Shunt

- Reversible Lower Casting

- 1” Electrode Holders w/ 90 & 30 degree positions

STANDARD SPECIFICATIONS

- KVA Rating: 30

- Secondary Voltage: 1 to 5 Volts

- Max. Secondary Amp: 17,000

- KVA Rating: 45

- Secondary Voltage: 1 to 6 Volts

- Max. Secondary Amp: 20,000

| Model | Throat Depth | Cylinder Bore | Electrode Force @ 100 P.S.I. | Capacity Mild Sheet (RWMA Standards) |

|---|---|---|---|---|

| (*)30-18 | 18 | 2 1/2 | 410 | 12 to 14 GA |

| (*)30-24 | 24 | 3 1/4 | 550 | 12 to 14 GA |

| (*)30-30 | 30 | 3 1/4 | 450 | 12 to 14 GA |

| Model | Throat Depth | Cylinder Bore | Electrode Force @ 100 P.S.I. | Capacity Mild Sheet (RWMA Standards) |

|---|---|---|---|---|

| (*)45-18 | 18 | 3 1/4 | 670 | 12 GA |

| (*)45-24 | 24 | 4 | 800 | 12 GA |

| (*)45-30 | 30 | 4 | 675 | 12 GA |

JANDA’s Rocker Arm spot welders offer great versatility for a wide variety of spot welding applications, satisfying all the requirements of HEAVY duty industrial applications.

Features:

- Heavy-duty steel frame

- Dual voltage on 20, 30 & 40 KVA

- Water-cooled Transformer , column & upper adaptor

- Swivel type lower casting

- Barrel lock arm & column

- Two stage foot switch w/ “O” shield

- Retraction

Optional:

- Tip Dress & Forge

| Model | Throat Depth | KVA | Cylinder Bore 4 | Capacity Mild Steel | Capacity Aluminum |

|---|---|---|---|---|---|

| R1-30-18 R1-30-24 |

18″ 24″ |

30 | 3″ 3 1/4″ |

14 GA | 0 |

| R1-40-24 R1-40-30 |

24″ 30″ |

40 | 3 1/4″ | 12 GA | 0.020 |

| R2-50-24 R2-50-30 |

24″ 30″ |

50 | 4″ | 10 GA | 0.030 |

| R2-75-24 R2-75-30 |

24″ 30″ |

75 | 4 1/2″ 5″ |

0.12 | 0.045 |

| R2-100-24 R3-100-24 R3-100-30 |

24″ 24″ 30″ |

100 | 5″ 6″ 6″ |

8 GA | 0.055 0.060 0.060 |

| R3-150-24 R3-150-30 |

24″ 30″ |

150 | 6 1/2″ | 6 GA | 0.090 0.080 |

| R3-200-24 R3-200-30 |

24″ 30″ |

200 | 7″ 8″ |

1/4″ | 0.100 0.090 |

| R3-250-30 | 30″ | 250 | 8″ | 5/16″ | 0.125 |