Welding

We supply Class 2 Copper, Glidcop, Molybdenum, Copper-Tungsten, and Pure Tungsten electrode materials.

Our square and round rods are typically precision ground, though a few are available as unground drawn rod. Please specify your size and required tolerance when requesting a quote.

Many more sizes and materials are available than are listed here.

| Material | Size |

|

| Glidcop | .125" diameter rod | |

| Glidcop | .250" diameter rod | |

| Glidcop | .123" x .123" square rod | |

| Molybdenum | .0625" diameter rod | |

| Molybdenum | .125" diameter rod | |

| Molybdenum | .1875" diameter rod | |

| Molybdenum | .250" diameter rod | |

| Molybdenum | .125" x .125" square rod | |

| Class 2 Copper | .125" diameter rod | |

| Class 2 Copper | .250" diameter rod | |

| Class 2 Copper | .125" x .125" square rod | |

| Tungsten | .0625" diameter rod | |

| Tungsten | .125" diameter rod |

Advanced Integrated Technologies Inc ( AIT ) supplies RWMA electrode materials used in the resistance welding and reflow soldering industries, including Glidcop and Molybdenum. Our business of manufacturing welding electrodes, reflow soldering thermodes, and hot bars has led us to stock various sizes and quantities of these exotic alloys. Glidcop is an alloy with a minimum mill order close to one thousand dollars. Many companies who wish to make their own electrodes don’t wish to buy that large a quantity of material from the mill. We sell Glidcop, Molybdenum, and many other RWMA electrode materials in sizes commonly used for micro resistance welding, and we have no minimum order quantity. Listed below are a few of the most common materials and sizes that we stock, but we have many other metals and sizes available including Berylium Copper, Copper Tungsten, Haynes 230, Nickel 200, Hastelloy, Tantalum, Inconnel 600, Inconnel 601, Inconnel 750, Monel 400, Tungsten HD17, 2% Thoriated Tungsten, and Titanium 6AL4V. Call AIT today if you need to buy Glidcop or other RWMA alloys.

Many electrode compositions are in common use in resistance welding. The choice is usually determined by the materials to be welded. AIT offers an electrode material selection chart at below. Six different electrode compositions are described below and may be ordered from AIT. The user’s selection of welding metals is not restricted, however, to those listed here.

- RWMA Class 1, Copper-Zirconium Alloy: suitable for welding aluminum alloys, magnesium alloys, coated materials, brass and bronzes.

- RWMA Class 2, Copper-Chromium Alloy: (Glidcop is often substituted for this alloy) This welding metal may be used to weld iron-base, nickel-base, cobalt-base, and chromium-base alloys. Class 2 electrodes are the most versatile general purpose alloys. AIT still builds many class 2 electrodes, but most customers are switching to Glidcop due to its superior qualities.

- RWMA Class 3, Copper-Cobalt-Beryllium Alloy: Having the same general applications as the RWMA Class 2 above, this metal sacrifices a small amount of conductivity for increased hardness. The characteristic hardness of Class 3 materials make them desirable for use as electrode-jigs and fixtures in high-production applications.

- RWMA Class 11, Copper-Tungsten Alloy: This material is used only as an insert in copper shanks. Generally, this class is used on precious metals and copper-base alloys. If sticking is evident, change to a Molybdenum or Class 13 electrode material.

- RWMA Class 13, Tungsten: Also used as an insert in a copper shank, Class 13 metals are used for copper, copper-base alloys and precious metals. The material is difficult to form into special shapes and fractures easily.

- RWMA Class 14, Molybdenum Alloys: These are the most popular electrode metals for welding copper-base and other highly conductive alloys. They minimize the sticking often encountered with copper-alloy electrodes.

Glicop is a dispersion strengthened copper with 0.15% aluminum oxide, 68B Rockwell hardness, 92% conductivity. This material offers longer life, greater thermal stability, and higher strength than RWMA 2. Glidcop is generally interchangeable with RWMA 2 (class 2 copper) without changing schedules. Many customers are switching from Class 2 to Glidcop with good results. We can supply your RWMA electrode materials. Call us today for more details.

| ELECTRODE SELECTION GUIDE | |

| The number which follows each material is the RWMA (Resistance Welder Manufacturers' Association) number of the electrode which would normally be placed against that material. For Example, when welding Alumel to Consil, a RWMA -2 electrode should be used on the Alumel side, and a RWMA -11 on the Consil side. Not all combinations have been tried successfully. | |

| Material | RWMA Electrode Type |

| Alumel | -2 |

| Aluminum | -1 |

| Aluminum Alloys | -1 |

| Beryllium Copper | -2 |

| Brass | -2, -11 |

| Brass, Tinned | -14 |

| Bronze | -2 |

| Cadmium Plating | -1 |

| Chromel | -2 |

| Consil | -11 |

| Constantin | -2 |

| Copel | -2 |

| Copper | -14 |

| Copper, Tinned | -14 |

| Dumet | -2 |

| Dumet, Gold Plated | -2 |

| Evenohm | -14 |

| Gold | -11 |

| Hastalloy | -2 |

| Inconel | -2 |

| Invar | -2 |

| Iridium | -2 |

| Iron | -2 |

| Karma | -2 |

| Kovar | -2 |

| Kovar, Gold Plated | -2 |

| Kulgrid | -2 |

| Magnesium | -1 |

| Manganin | -2 |

| Molybdenum | -2 |

| Nichrome | -2 |

| Nickel | -2 |

| Nickel Alloy | -2 |

| NiSpan C | -2 |

| Nioblum | -2 |

| Paliney 7 | -2 |

| Palladium | -14 |

| Platinum | -2 |

| Rhenium | -2 |

| Silver | -11 |

| Steel, Cold Rolled | -2 |

| Steel, Stainless | -2 |

| Tantalum | -2 |

| Titanium | -2 |

| Tungsten | -2 |

| Zinc | -14 |

Electrode Shanks

Back Up Electrodes

Call us today at 1-888-304-4367 for assistance!

Click here for available models.

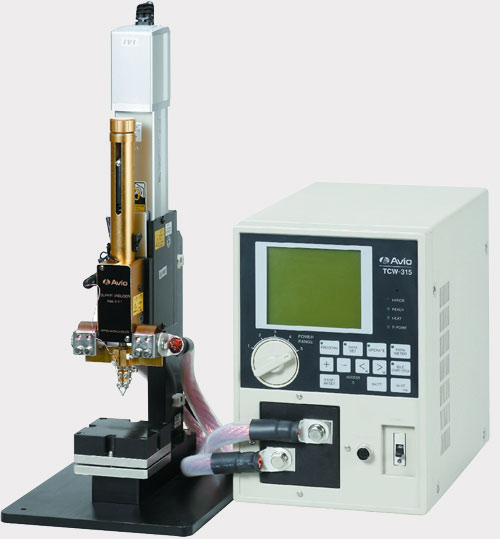

Although the Hughes Welder has not been manufactured for several years now, Advanced Integrated Technologies Inc ( AIT ) still supplies electrodes and new replacement welders for the obsolete Hughes Welder designs. Today we distribute and recommend the Avio welder and the Sunstone Welder, both of which are excellent replacements for the obsolete Hughes Welder. Request a quote from us today on a welder, electrodes, or any other items you may need related to micro welding or soldering. Our customer support team is standing by.

Although the Hughes Welder has not been manufactured for several years now, Advanced Integrated Technologies Inc ( AIT ) still supplies electrodes and new replacement welders for the obsolete Hughes Welder designs. Today we distribute and recommend the Avio welder and the Sunstone Welder, both of which are excellent replacements for the obsolete Hughes Welder. Request a quote from us today on a welder, electrodes, or any other items you may need related to micro welding or soldering. Our customer support team is standing by.

Advanced Integrated Technologies Inc ( AIT ) has been building electrodes and hot bar thermodes for all styles and models of the Hughes Welder, as well as all other brands of welders and hot bar bonding machines, since 1982. Our product line includes many standard designs of parallel gap and opposed electrodes. We also manufacture many designs of hot bar and fold up thermodes for reflow soldering and heat seal bonding. AIT’s products are top quality and very economical by comparison to those of original equipment manufacturers. Much of our business involves custom design and manufacturing of electrodes and thermodes for customers requiring special applications. If you are running the Hughes Welder or any other welding or soldering equipment, call us today for more information.

The concept for using welding technology for interconnection of electronic connections was first proposed by a Hughes’ Aircraft research scientist in 1954. Hughes Aircraft went on to develop and manufacture the Hughes Welder under the Hughes Technology Products Division of the Hughes Industrial Electronics Group in Carlsbad, California.

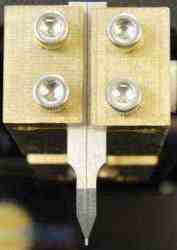

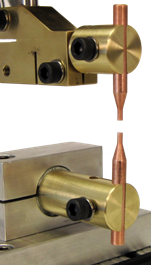

Advanced Integrated Technologies Inc came on the micro welding scene in about 1982. Hughes was developing a microparallel gap welding tool called a duo tip. They were unable to get these micro tools successfully built anywhere in California. Paul Balentine, founder of AIT, successfully built the micro tools by grinding them on a lathe fitted with a tool post grinder. Later when he had secured the contract he built a specialized grinding station with a camera and overlay system to control the grinding process. AIT was the first to build these micro parallel gap welding electrodes for the Hughes Welder, and continues to be the industry leader today.

In the 1970's, Palomar Technologies was established within the Assembly and Test Products line of Hughes Aircraft Industrial Products Division. For a while the Hughes Welder was often called the Palomar Hughes Welder. Eventually through a series of mergers and acquisitions, the core Hughes Welder technology was absorbed into the Unitek Miyachi product line which still operates today. Advanced Integrated Technologies Inc ( AIT ) supplies resistance welding electrodes and reflow solder tips for Unitek Miyachi welders and reflow soldering machines. There are however many Hughes and Palomar Hughes Welders still in use today, which is why AIT is the largest and most well known supplier of tools for these machines.

Advanced Integrated Technologies Inc ( AIT ) has a standard product line, but is not limited to that product line alone. Over 50% of our business is designing and building custom tools for customers’ unique applications. Our combination of manufacturing experience and efficiency allow us to build affordable tools for the Hughes Welder and Unitek style welders and soldering machines.

The Sunstone welder is an American made welder of good quality and good customer support. Sunstone manufactures capacitive discharge spot welders, AC welders, and pulse arc welders. A good selection of Sunstone products are listed on this page, and you can request a quote for any of this by calling us or submitting a contact form. Please note that all Sunstone equipment prices are fixed by the manufacturer. Although we are not allowed to discount the price of the welder, we can offer other discounts on shipping and electrodes if you purchase from us. If you are shopping for weld equipment, take advantage of our free test weld offer. We can evaluate your product samples, perform a variety of weld tests, and recommend the best equipment for your application.

About Avio Welders

The Avio welder is a technologically advanced welder of excellent quality and good customer support. Nippon Avionics manufactures capacitive discharge spot welders, AC welders, transistor welders (linear DC), inverter welders, and hybrid battery tab welders. A good selection of Avio products are listed on this page, and you can request a quote for any of this by calling us or submitting a contact form. If you are shopping for weld equipment, take advantage of our free test weld offer. We can evaluate your product samples, perform a variety of weld tests, and recommend the best equipment for your application.

Welding Power Supplies

Avio Power Supplies will not be listed in detail on this page. They are listed on the Capacitive Discharge Welder, AC Spot Welder, Inverter Spot Welder, Linear DC Welder, and Battery Tab Welder pages of this website

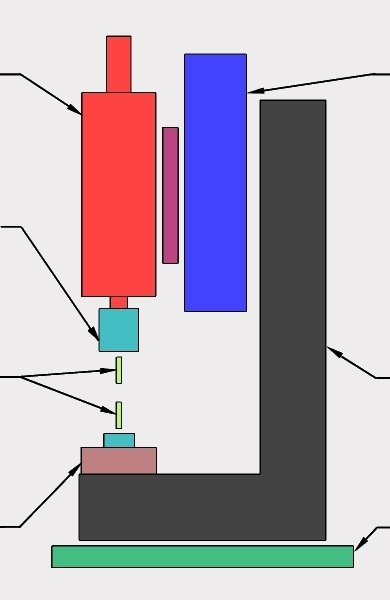

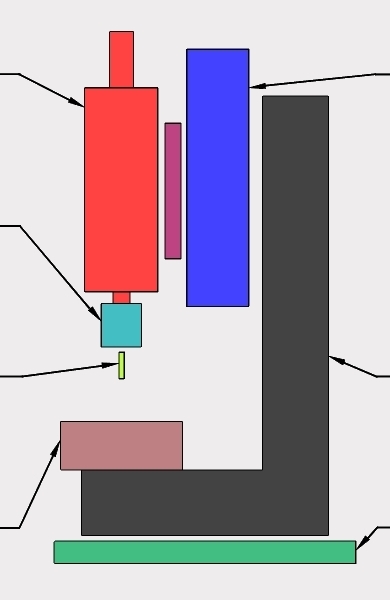

Weld Head Components Illustration

| Opposed Weld Head Illustration | Parallel / Series Weld Head Illustration | ||||||||||||||||||

|

|

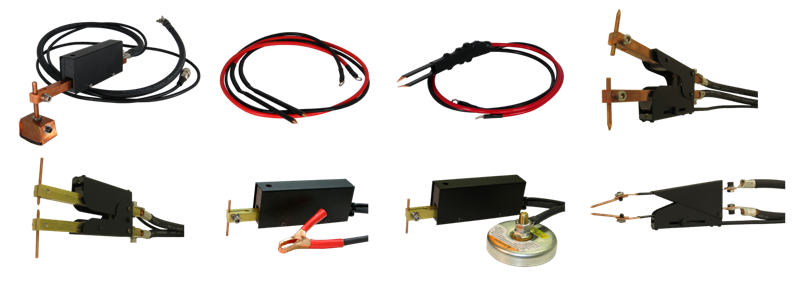

Some welding applications don't fit well in a weld head, or require more flexibility. Hand held welding attachments allow welding of complex geometries. Also hand held attachments are less expensive than weld heads. Welding attachments are easy to use, require low maintenance, and provide a lot of flexibility for small production runs or laboratory applications. Review the information below for technical data and images of the various hand pieces available.

How We Can Help You

Advanced Integrated Technologies ( AIT ) is a resistance welding equipment and technical support provider for Nippon Avionics ( Avio ) brand of resistance tweezer welders and accessories as well as Sunstone brand tweezer welders. We can evaluate your product samples, provide free test welds, and accurately specify which equipment is best for your application. We can then provide the equipment you need at an economical price, and assist with any technical issues you encounter setting up your welding process. Submit a contact form or call us today to request assistance with your next project.

Avio Hand Piece Type Welders

The welding machine series of hand operated models are arranged to weld a difficult object that can't be welded by a fixed type weld head, like at a jamming area. No side-to-side rocking of electrodes. Operating with low power due to their compact and lightweight size.

The welding machine series of hand operated models are arranged to weld a difficult object that can't be welded by a fixed type weld head, like at a jamming area. No side-to-side rocking of electrodes. Operating with low power due to their compact and lightweight size.

NA-54A

| Features | NA-54A |

| Pressure Range (N) | 7.8-44.1 |

| Electrode Stroke | 10mm Max |

| Depth Dimension of Pocket | 50mm |

| Driving Method | Manual |

| Applicable Electrode | EL-125 Series |

| Dimensions (mm) | 30x195x47 |

| Weld Cable | 1500mm |

NA-54LA

| Features | NA-54LA |

| Pressure Range (N) | 7.8-44.1 |

| Electrode Stroke | - |

| Depth Dimension of Pocket | - |

| Driving Method | Manual |

| Applicable Electrode | EL-54L |

| Dimensions (mm) | 30x195x47 |

| Weld Cable | 1500mm |

NA-57A

| Features | NA-57A |

| Pressure Range (N) | 9.8-49 |

| Electrode Stroke | - |

| Depth Dimension of Pocket | - |

| Driving Method | Manual |

| Applicable Electrode | Specialized for NA-57A |

| Dimensions (mm) | 36Φ xD207mm |

| Weld Cable | 1500mm |

NA-58A

| Features | NA-58A |

| Pressure Range (N) | Manual |

| Electrode Stroke | 1mm Max |

| Depth Dimension of Pocket | 75mm |

| Driving Method | Manual |

| Applicable Electrode | Specialized for NA-58A |

| Dimensions (mm) | 24x16x157 |

| Weld Cable | 1100mm |

Sunstone Tweezer Welder Attachments

Some welding applications don't fit well in a weld head, or require more flexibility. Hand held welding attachments allow welding of complex geometries. Also hand held attachments are less expensive than weld heads. Welding attachments are easy to use, require low maintenance, and provide a lot of flexibility for small production runs or laboratory applications. Review the information below for technical data and images of the various hand pieces available.

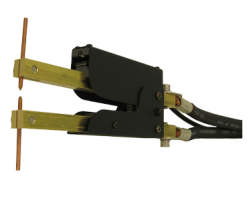

PTHP LP - Pressure Actuated Tweezer

Hand Piece

Hand Piece

Features:

• Opposed welding hand piece

• Accepts 3/16” electrodes

• 1 pair of RWMA II electrodes (EL187RWMA-ANG)

• Molybdenum electrodes available

• Pressure Range 0.5 – 6 lbf

• 8 AWG cabling standard

| (PTHP LP) Pressure-Actuated Tweezer Hand Piece - Low Power |

|

| Spring Force | 1 - 6 lbs |

| Electrode Size | 3/16” |

| Dimensions | .75" x 2.5" x 7" |

| Weight | .56 lb / .25 kg |

| CD Welder | 100 - 1000 (ws) |

| AWG for CD | 8 AWG |

| AC Welder (kVA) | 1.5 kVA |

| AWG for kVA | 4 AWG |

PTHP MP - Pressure Actuated Tweezer

Hand Piece

Hand Piece

Features:

• Opposed welding hand piece

• Accepts 3/16” electrodes

• 1 pair of RWMA II copper electrodes

• Tungsten electrodes available

• Pressure Range 1 – 10 lbf

• 4 AWG cabling standard

| (PTHP-MP) Pressure-Actuated Tweezer Hand Piece - Medium Power |

|

| Spring Force | 1 - 10 lbs |

| Electrode Size | 3/16” |

| Dimensions | 1" x 3" x 6" |

| Weight | 1.3 lb / .59 kg |

| CD Welder | 100 - 1000 (ws) |

| Wire AWG | 4 AWG - 1 AWG |

| AC Welder (kVA) | 2.5 kVA |

| AWG for kVA | 3 AWG |

PTHP HP - Pressure Actuated Tweezer

Hand Piece

Hand Piece

Features:

• Opposed welding hand piece

• Accepts 3/16” electrodes

• 1 pair of RWMA II copper electrodes

• Tungsten electrodes available

• Pressure Range 1 – 10 lbf

• 1 AWG cabling standard

| (PTHP-HP) Pressure-Actuated Tweezer Hand Piece - High Power |

|

| Spring Force | 1 - 10 lbs |

| Electrode Size | 3/16" |

| Dimensions | 1" x 3" x 6" |

| Weight | 1.4 lb / .64 kg |

| CD Welder | 1000 ws |

| Wire AWG | 1 AWG |

| AC Welder (kVA) | 5.0 kVA |

| AWG for kVA | 3 AWG |

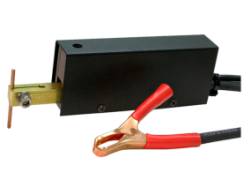

PASP HP CP - Pressure-Activated Single

Probe Hand Piece Alligator Clip

Probe Hand Piece Alligator Clip

Features:

• Pressure-actuated for repeatability

• Adjustable pressure set-point

• For hard-to-reach welds

• 1/8” RWMA II Electrode

• Large alligator clip for simple setup

• 6 AWG cabling standard

| PASP - Alligator Clip | |

| Spring Force | 1 -6 lbs |

| Electrode Size | 1/8" |

| Dimensions | 1.125" x 3.5" x 9" |

| Weight | 3.35 lb / 1.5 kg |

| CD Welder | 100-1000 (ws) |

| Wire AWG | 6 AWG |

| AC Welder (kVA) | 2.5 kVA |

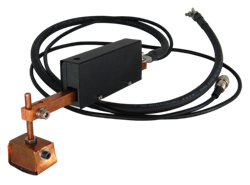

PASP HP MAG - Pressure-Activated

Single Probe Hand Piece Magnetic

Single Probe Hand Piece Magnetic

Features:

• Pressure-actuated for repeatability

• Adjustable pressure set-point

• For hard-to-reach welds

• 1/8” RWMA II Electrode

• Large magnetic clip for simple setup (iron base material)

• 6 AWG cabling standard

| PASP - Magnetic Clip | |

| Spring Force | 1 -6 lbs |

| Electrode Size | 1/8" |

| Dimensions | 1.125" x 3.5" x 9" |

| Weight | 3.35 lb |

| CD Welder | 300-1000 (ws) |

| Wire AWG | 6 AWG - 1 AWG |

| AC Welder (kVA) | 2.5 kVA |

PASP HP H - Pressure-Activated Single

Probe Hand Piece Honeycomb

Probe Hand Piece Honeycomb

Features:

• Pressure-actuated for repeatability

• Adjustable pressure set-point

• Honeycomb Tack Electrode (either radiused or Flat)

• Large alligator clip for simple setup

• 1 AWG cabling standard

| PASP - Honeycomb | |

| Electrode Size | 1/4” |

| Dimensions | 1.125" x 3.5" x 9" |

| Weight | 4 lbs / 1.8 kg |

| CD Welder | 1000 ws |

| Wire AWG | 4 AWG - 1 AWG |

| AC Welder (kVA) | 5.0 kVA |

SPHP - Single Probe Hand Piece

Features:

• 1/4” diameter copper shank

• 8 AWG cabling

| (SPHP) Single Probe Hand Piece | |

| Electrode Size | 1/4" |

| Weight | 0.55 lb / 0.25 kg |

| CD Welder | 200-1000 ws |

| AWG for CD | 8 AWG |

| AC Welder (kVA) | 1.5 kVA - 5.0 kVA |

| AWG for kVA | 4 AWG |

DPHP - Dual Probe Hand Piece

Features:

• 1/4” diameter RWMA II copper shank

• 8 AWG cabling

| (DPHP) Dual Probe Hand Piece | |

| Electrode Size | 1/4" |

| Weight | .65 lbs |

| CD Welder | 200-1000 ws |

| AWG for CD | 8 AWG |

| AC Welder (kVA) | 1.5 kVA - 5.0 kVA |

| AWG for kVA | 4 AWG |

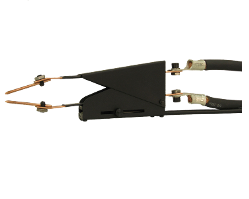

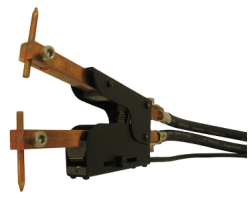

THP - Tweezer Hand Piece

Features:

• Opposed welding hand piece

• Opposed welding hand piece

| (THP) Tweezer Hand Piece | |

| Copper Bar Size | 1.2" x 1/16" |

| Weight | .8 lbs |

| CD Welder | 200-1000 ws |

| AWG for CD | 8 AWG |

| AC Welder (kVA) | 1.5 kVA - 5.0 kVA |

| AWG for kVA | 4 AWG |

PG2

Pistol Grip Hand Piece with Button Trigger. Accepts

threaded electrodes.

threaded electrodes.

Features:

• Easy to handle

• Conveniently placed trigger switch

| PGHP - Poke Gun Hand Piece | |

| Electrode Size | 3/8” |

| Dimensions (W x H x L) | 1” x 3” x 6” |

| Weight lb/kg | 1.3 lb / .59 kg |

| CD Welder (ws) | 100 - 1000 (ws) |

| Wire AWG | Wire AWG 4 AWG - 1 AWG |

| AC Welder (kVA) | 2.5 kVA |

Probe Hand Piece Roll Spot

Features:

• Pressure-actuated for repeatability

• Adjustable pressure set-point

• 2” copper wheel (EL-ROLL)

• Large alligator clip for simple setup

• 1 AWG cabling standard

| PASP - Roll Spot | |

| Electrode Size | 1/4” Shank |

| Dimensions (W x H x L) | 1.125” x 3.5” x 9” |

| Weight lb/kg | 1.3 lb / .59 kg |

| CD Welder (ws) | 100 - 1000 (ws) |

| Wire AWG | Wire AWG 4 AWG - 1 AWG |

| AC Welder (kVA) | 2.5 kVA |

SPHP LP

Features:

• 1/4” diameter brass shank

• 8 AWG cabling

• Accepts 1/16” or 2mm diameter electrode

| Single Probe Hand Piece - Low Power | |

| Electrode Size | 1/16” |

| Weight lb/kg | 1.5 lb / 0.68 k |

| CD Welder (ws) | 100 - 400 (ws) |

| Wire AWG | 8 AWG |

| AC Welder (kVA) | 1.5 kVA - 5.0 kVA |

SPHP MP

Features:

• 5/8” diameter brass shank

• 4 AWG cabling

• Accepts 1/8” diameter electrode

| Single Probe Hand Piece - Medium Power | |

| Electrode Size | 1/8” |

| Weight lb/kg | 2 lb / 0.9 kg |

| CD Welder (ws) | 320 - 1000 (ws) |

| AWG for CD | 4 AWG |

| AC Welder (kVA) | 1.5 kVA - 5.0 kVA |

SPHP HP

Features:

• 7/8” diameter brass shank

• 1 AWG cabling

• Accepts 3/16” diameter electrode

| Single Probe Hand Piece - High Power | |

| Electrode Size | 3/16” |

| Weight lb/kg | 3.5 lb / 1.6 kg |

| CD Welder (ws) | 320 - 1000 (ws) |

| AWG | 1 AWG |

| AC Welder (kVA) | 1.5 kVA - 5.0 kVA |

DPHP Micro

Features:

• For thermalcompression bonding

• 10 AWG cabling

| Dual Probe Hand Piece - Micro | |

| Electrode Size | 1/8” Shank |

| Weight lb/kg | 2 lb / 1 kg |

| DC Welder (ws) | DCD 320/DC-5 |

| AWG | 10 AWG |

| AC Welder (kVA) | 1.5 kVA - 2.5 kVA |

DPHP LP

Features:

• 1/4” diameter brass shank

• 8 AWG cabling

• Accepts 1/16” diameter electrodes

| Dual Probe Hand Piece - Low Power | |

| Electrode Size | 1/16” |

| Weight lb/kg | 2 lbs / 0.9 kg |

| CD Welder (ws) | 100 - 1000 (ws) |

| Wire AWG | 8 AWG |

| AC Welder (kVA) | 1.5 kVA - 5.0 kVA |

DPHP MP

Features:

• 5/8” diameter brass shank

• 4 AWG cabling

• Accepts 1/8” diameter electrodes

| DPHP MP - Dual Probe Hand Piece - Medium Power | |

| Electrode Size | 1/8” |

| Weight lb/kg | 2 lbs / 0.9 kg |

| CD Welder (ws) | 100 - 1000 (ws) |

| Wire AWG | 4 AWG |

| AC Welder (kVA) | 1.5 kVA - 5.0 kVA |

DPHP HP

Features:

• 7/8” diameter brass shank

• 1 AWG cabling

• Accepts 3/16” diameter electrodes

| DPHP LP - Dual Probe Hand Piece - High Power | |

| Electrode Size | 3/16” |

| Weight lb/kg | 3 lb / 1.36 kg |

| CD Welder (ws) | 100 - 1000 (ws) |

| Wire AWG | 1 AWG |

| AC Welder (kVA) | 1.5 kVA - 5.0 kVA |

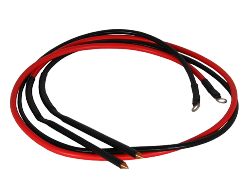

HP RWMA Package

Hand Piece RWMA II Package includes Sunstone’s

DPHP, SPHP, & THP-A weld attachments.

DPHP, SPHP, & THP-A weld attachments.

Features:

• Opposed welding hand piece

• 1/4” diameter RWMA II copper shank

• 8 AWG cabling

| Tweezer Hand Piece (RWMA) | |

| Copper Bar Size | 1/2” x 1/16” |

| Weight lb/kg | 2.5 lb / 0.36 kg |

| CD Welder (ws) | 100 - 1000 (ws) |

| Wire AWG | 8 AWG |

| AC Welder (kVA) | 1.5 kVA - 5.0 kVA |

THP-P

Features:

• Air-actuated tweezer-style hand piece

• Force ranges: 5-50lbs

• Adjustable throat up to 1.75”

• 1” Stroke Distance

• Designed to integrate with Sunstone’s ACS

• Can use 1/8” opposed electrodes

| THP P - Pneumatic Tweezer Hand Piece | |

| Force | 5 - 50 lbs |

| Copper Bar Size | 1/2” x 1/16” |

| Weight lb/kg | 2.5 lb / 0.36 kg |

| CD Welder (ws) | 100 - 1000 (ws) |

| Wire AWG | 1 AWG |

| AC Welder (kVA) | 1.5 kVA - 5.0 kVA |

PG5M

style="text-align: center;">The PG5M miniature pliers gun is the smallest in the

range. Designed for use in the electronics industry,

it offers a high degree of precision.

PG2W

The PG2W is a watercooled version of the PG2,

allowing use under higher duty cycle conditions.

Accepts threaded electrodes.

PG3W

Water cooled PG3 gun. Accepts compression

electrodes.

PG EL125 - Adapter

Threaded adapter for the Poke hand pieces, accepts

a 1/8th inch electrode.

a 1/8th inch electrode.

PG EL187 - Adapter

Threaded adapter for the Poke hand pieces, accepts

a 3/16th inch electrode.

a 3/16th inch electrode.

PG EL

3/8” Diameter, Tapered Copper Electrode

(threaded) for PG2 and PG1

(threaded) for PG2 and PG1

PG EL-Roll T

2” Copper Wheel electrode, threaded fitting style.

PG EL-Roll C

2” Copper Wheel electrode, compression fitting

style.

style.

PASP 2

Pressure-Actuated Single Probe Hand Piece

PG1

fitted with a straight or 90 degree tip and has a built

in switch. Accepts threaded electrodes.

PG1/2

The PG1/2 is the smallest single side gun. It can be

fitted with a straight or 90degree tip. Triggered with

a foot pedal. Accepts threaded electrodes.

PG4

The PG4 gun is designed as a series welder. This

gun will apply 2 spots simultaneously. Accepts

compression electrodes.

The purpose of a Seam Welder is to use pressure and electricity to seal a metal lid to a package in a vacuum, or nitrous environment, creating a sealed package with components inside. This protects the inside components from the environmental elements that would lead to degredation of the component, therefore extending the life and durability of the package device in a process known as "Hermetic Sealing." The package is vacuum sealed, the lid is Tack welded to the package, then roller electrodes roll along and weld the X and Y sides of the lid to the package creating a rim that looks like a seam in sewing, hence the name "Seam Welder". Seam Welders are used on packages that contain anything from crystal devices and MEMS to sensors and optical devices. Vacuum Seam Welding has become more prominent with the miniturization of many technical components, as well as the need for higher performance.

How We Can Help You

Advanced Integrated Technologies ( AIT ) is a welding equipment and technical support provider for Nippon Avionics ( Avio ) brand of Seam Welders and accessories.. We can evaluate your product samples, provide free test welds, and accurately specify which equipment is best for your application. We can then provide the equipment you need at an economical price, and assist with any technical issues you encounter setting up your welding process. Submit a contact form or call us today to request assistance with your next project.

Fully Automatic N2 Gas Type

Features

- Fastest Cycle Time 1.5s & High Availability

- Minimum PKG Size 2016

- High Reliability Sealing

- High Performance Sealing Head & PS

- Easy Maintenance & Product Shift

- Large Capacity & High Accuracy

- High Speed with Less Damage

- Seam Welding

- Tack Welding

- Vacuum Oven Chamber: Rotary, Dry, Turbo, Cryo pumps

- Lids Supply

- Dedicated Trays

- High Performance Sealing Head

- Dedicated Power Supply

- Glove Box

| Power Source:Main Body | AC200V 3Φ 20A |

| Power Source:Chamber | AC200V 3Φ 30A |

| Air | 0.5MPa |

| N2 Gas | 0.2MPa |

| Water | 0.5MPa |

| Dimensions | 2970W x 1320D x 1870H mm |

| Mass | 1,800kg |

Semi-Automatic N2 Gas Type

Features

- Various Operation modes available for R&D and mass production.

- PKG size 2~150mm - Rectangular, Round, Polygon

- Easy Operation & Programming

- Automatic Program Verification

- Single Head Type

- Vacuum Oven Chamber: Rotary, Dry, Turbo, Cryo pumps

- Glove Box

- Production Modes: Fast, Standard, Teaching

- High Performance Sealing Head

- Dedicated Power Supply

| Power Source | AC200V 3Φ 20A |

| N2 Gas | 0.2MPa~0.8MPa |

| Water | 0.2MPa |

| Dimensions | 2200W x 900D x 1550Hmm |

| Mass | 450Kg |

Twin Head Type

Features

- Various operation modes available for R&D and mass production.

- PKG size 2~150mm - Rectangular, Round, Polygon

- Easy Operation & Programming

- Automatic Program Verification

- Twin Head Type

- Vacuum Oven Chamber: Rotary, Dry, Turbo, Cryo pumps

- Glove Box

- Production Modes: Fast, Standard

- High Performance Sealing Head

- Dedicated Power Supply

- Automatic Program Verification

| Power Source | AC200V 3Φ 30A |

| N2 Gas | AC200V 3Φ 30A |

| Water | 0.2MPa |

| Dimensions | 2300W x 800D x 1300Hmm |

| Mass | 550Kg |

Fully Automatic Vacuum Type

Features

- Fastest Cycle Time 1.5s & High Availability

- Minimum PKG Size 2016

- High Reliability Sealing

- High Performance Sealing Head & PS

- Easy Maintenance & Product Shift

- Large Capacity & High Accuracy

- High Speed with Less Damage

- Seam Welding

- Tack Welding

- Vacuum Oven Chamber: Rotary, Dry, Turbo, Cryo pumps

- Lids Supply

- Dedicated Trays

- High Performance Sealing Head

- Dedicated Power Supply

- Glove Box

| Power Source:Main Body | AC200V 3Φ 40A |

| Power Source:Chamber | AC200V 3Φ 30A |

| Air | 0.5MPa |

| N2 Gas | 0.2MPa |

| Water | 0.5MPa |

| Dimensions | 3950W x 1320D x 1870H mm |

| Mass | 2,045kg |

Semi-Automatic Vacuum Type

Features

- Various operation modes available for R&D and mass production.

- PKG size 2~150mm - Rectangular,round,polygon

- Easy Operation & Programming

- Automatic Program Verification

- Vacuum Oven Chamber: Rotary, Dry, Turbo, Cryo pumps

- Glove Box

- Production Modes: Fast, Standard, Teaching

- High Performance Sealing Head

- Dedicated Power Supply

- Seam Welding Chamber

| Power Source | AC200V 30A |

| N2 Gas | 0.2-0.8 MPa |

| Water | 0.2MPa |

| Air | 0.5MPa |

| Dimensions | 2000w x 900D x 19000Hmm |

| Mass | 550kg |

Dedicated Tack Welder NAW-1246

Optimum solution to products and volume of productions

- Lids Supply

- Cassette

- Parts Feeder

| Power Source:Body | AC200V 1Φ 20A |

| Air | 5kgf/cm² |

| Dimensions | 1200Wx1000Dx1870H mm |

| Mass | 400kg |

AIT Offers the AVIO line of Ultra Precision Micro Spot Welders

![]() Providing you with equipment and technical support

Providing you with equipment and technical support

![]() Lower prices on equipment and electrodes than other manufacturers

Lower prices on equipment and electrodes than other manufacturers

![]() Shorter lead time, especially on electrodes

Shorter lead time, especially on electrodes

![]() Free test welds and excellent customer support

Free test welds and excellent customer support

How We Can Help You

A great way to prepare for purchasing a welder is to take advantage of our free test welds to help you decide if a transistor welder is the proper weld equipment for the task. We are an equipment and technical support provider for Nippon Avionics ( Avio ) brand of precision inverter welders. At AIT, we have chosen the Nippon Avionics ( AVIO ) line of equipment because we have found that you recieve more advanced technology, quality, and precision for your money than with other brands. We can provide the equipment you need at an economical price, and assist with any technical issues you encounter. Submit a contact form or call us today to request assistance with your next project.

AVIO Micro Spot Welders

-

The best choice for welding micro wires and components

-

Accurate and consistent welding using high speed linear control

-

Three Operation Feedback modes (constant current, voltage, or power)

-

High speed welding (up to 5 shots / second)

-

Pre-weld check function reduces spark problems

- Voltage, current, and power wave forms displayed simultaneously in a graph

| Features | MCW-700 | MCW-750 |

| Maximum Current | 500A | 1800A |

| Maximum Voltage | 2V | 4V |

| Constant Current Mode | 10 - 500A (1A Step) | 10 - 1800A (1A Step) |

| Constant Voltage Mode | 0.001 - 2V (1mV Step) | 0.01 - 4V (10mV Step) |

| Constant Power Mode | 10 - 500W (1W Step) | 10 - 3600W (1W Step) |

| Weld Time : Up | 0 -999 x 0.01ms or x 0.1ms | |

| Weld Time : Weld | 0 -999 x 0.01ms or x 0.1ms | |

| Weld Time : Down | 0 -999 x 0.01ms or x 0.1ms | |

| Weld Time : Squeeze&Hold | 9.99s (maximum) | 9.99s (maximum) |

| Pre-Check | Resistance/Current | Resistance/Current |

| Shot / Sec | 5shots / sec: 500W 2ms | 5 shots / sec : 3600W 2ms |

| Monitor : Wave Form | Current / Voltage / Power | Current / Voltage / Power |

| Monitor : Current | Average / Peak | Average / Peak |

| Monitor : Voltage | Average / Peak | Average / Peak |

| Monitor : Power | Average / Peak | Average / Peak |

| Number of Conditions | 15 | 15 |

| Interface | RS-232, I/O, analog output | RS-232, I/O, analog output |

| Power Source (Option) | 100-120V AC (200-240V AC) | 100-120V AC (200-240V AC) |

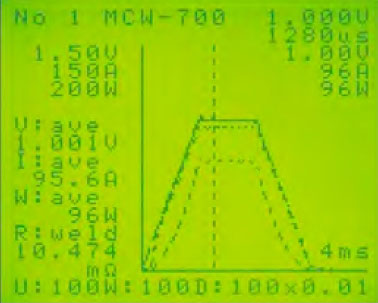

Real Time Welding Wave Form Display

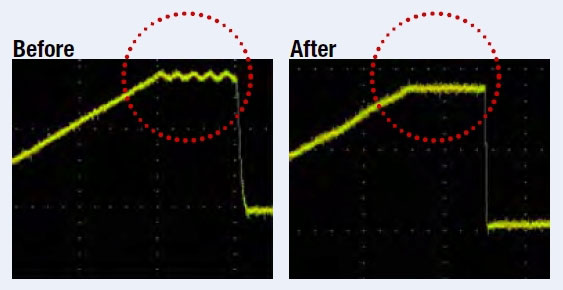

PID Adjustment - Before and After

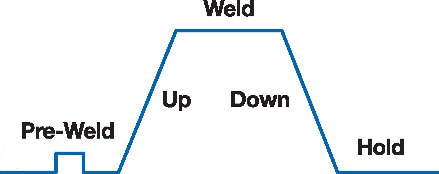

Micro spot welders are also known as Linear DC welders. Micro spot welders load up energy in capacitors and release it through transistors. This produces a result very similar to the high frequency inverter power supplies. Clean square waves are created as the output with fast rise time. The micro spot welders made by AVIO are closed loop designs, using transistor controlled feedback with fast response time, with the ability to monitor the condition of the weld using one of three feed back modes, "constant current", "constant voltage", or "constant power". These feedback modes offer benefits such as excellent process consistency between multiple weld stations, fewer bad welds, and immediate automatic adjustment for variations in thermal loading and plating. Linear DC welders do not use a transformer. These power supplies' low energy controls are the best, making them the favorite for welding foils and micro wires. The fact that the duty cycle is typically less than one weld per second is the biggest limitation.

The Avio welders we offer are high quality Japanese welders. We stand by these welders and guarantee our customer's support and assistance when you purchase an Avio welder from us. AIT manufactures all electrodes in the U.S.A. Your questions and inquiries will be responded to quickly.

Welding Wave Form

The Sunstone welder is an American made welder of good quality and good customer support. Sunstone manufactures capacitive discharge spot welders, AC welders, and pulse arc welders. A good selection of Sunstone products are listed on this page, and you can request a quote for any of this by calling us or submitting a contact form. Please note that all Sunstone equipment prices are fixed by the manufacturer. Although we are not allowed to discount the price of the welder, we can offer other discounts on shipping and electrodes if you purchase from us. If you are shopping for weld equipment, take advantage of our free test weld offer. We can evaluate your product samples, perform a variety of weld tests, and recommend the best equipment for your application.