Welding

AIT offers a complete line of Resistance Spot Weld Heads for both Avio and Sunstone

About Weld Heads

Weld Heads come in a vast array of configurations. Avio weld heads come in two major divisions, being monolithic type, and modular type. Monolithic heads are an all in one type weld head with a fixed force range. Some of these are air operated, and some are manual. Different models cover different force ranges, electrode diameters, and electrode orientations. Modular heads are composed of different combinations of components. The system head is chosen by electrode orientation and force range needed. The drive unit is chosen by how the user would like to control the head, either air, manual, or servo. Holders, bases, and stages are all chosen for the type of electrode orientation, and electrode size needed. All these above mentioned components are then mounted onto the appropriate base and pallet, unless they are otherwise being integrated into some type of automated machinery. Avio has many modular configurations available. Sunstone heads are more like monolithic heads.

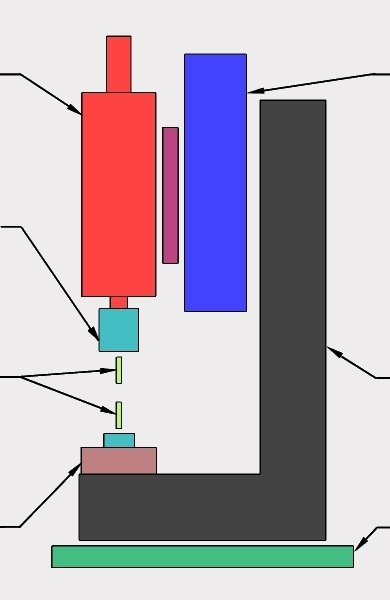

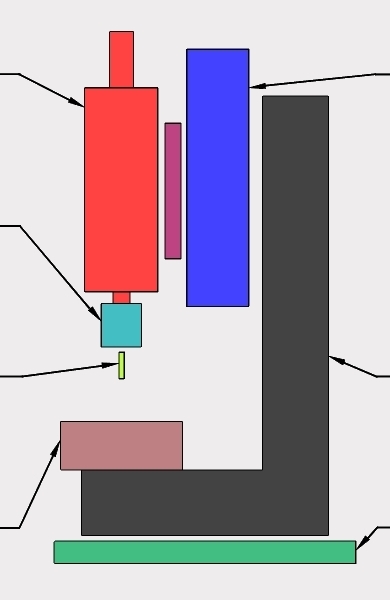

The illustrations below show the opposed electrode orientation, and the parallel electrode orientation, for modular Avio type weld heads. You can click on the different labels/links around the images to see the Avio components in detail on another page of this site. Continue reading below for more discussion about various weld head options and configurations.

For Sunstone Weld Heads, click here.

For Avio weld heads , click the links around the images below.

Series Head

Electrode Orientation refers to whether the electrodes approach from above, or from both sides of the work piece. Opposed designs have a bottom and a top electrode. Typically the bottom electrode is fixed, and the top electrode moves and provides the down force. Some types of heads like the Avio NA-43 have the electrode oriented horizontally instead of vertically. Parallel designs have both electrodes approaching from the same side, typically from the top. Parallel designs are further broken down into Parallel and Series weld heads. True Parallelheads hold both electrodes in a fixed relationship to each other, meaning that the electrode tips must touch the work piece at the same time under the force of a single spring. These type of electrodes can be bonded together with an adhesive insulator, or free such that the electrode holder sets the height relationship between the left and right electrodes. Series type weld heads have double springs, such the the left and right electrodes are independently spring loaded. This allows each electrode to come to a resting point on the work piece under their own pressures, compensating for varying work heights. Most battery tab welding is done with this type of head.

Both Opposed and Parallel heads come in a variety of actuation configurations. Air operated heads are actuated by a foot switch that fires a solenoid, which applies compressed air to an air cylinder, which in turn drives the head downward. As the head is driven down, a switch fires the weld sequence when the head achieves the correct down force. Then afterward the solenoid releases the air valve, which retracts the upper electrode. Manual actuated heads have a mechanical foot switch that the operator uses to pull the upper head down. When the head senses that it has achieved the correct pressure, it fires the weld cycle. The operator then releases the foot switch, allowing the head to retract. Servo actuated heads use a servo driver and servo motor to drive the head down to a set position each time. These are used for greater speed and control over the welding process. For example, a servo head can rapid very quickly to the work piece, decelerating a millimeter before the electrodes touch, and then applying pressure softly as the electrode contact the work piece. Monolithic heads are typically either manual or air operated.

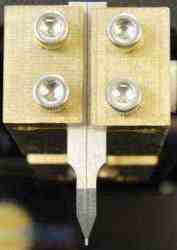

Electrode holders also have options for what type of electrode they can hold. Some electrodes, mostly the parallel design, are square or rectangular bodied. Other types are round bodied. The round body electrodes typically come in 1/16", 1/8", 1/4", or 1/2" diameter designs, or their metric equivalents in the case of Avio electrodes.

AIT offers a complete line of high quality AC Spot Welders

![]() High quality AC Welding Power Supplies, Transformers, and Accessories

High quality AC Welding Power Supplies, Transformers, and Accessories![]() Lower prices on equipment and electrodes than other manufacturers

Lower prices on equipment and electrodes than other manufacturers![]() Shorter lead time, especially on electrodes

Shorter lead time, especially on electrodes![]() Free test welds and unparalleled customer support

Free test welds and unparalleled customer support

Click here for matching weld heads.

How We Can Help You

Advanced Integrated Technologies ( AIT ) is a resistance welding equipment and technical support provider for Nippon Avionics ( Avio ) brand of resistance spot welders and accessories as well as Sunstone brand spot welders. We can evaluate your product samples, provide free test welds, and accurately specify which equipment is best for your application. We can then provide the equipment you need at an economical price, and assist with any technical issues you encounter setting up your welding process. Submit a contact form or call us today to request assistance with your next project.

AVIO Welders

These AC spot welders are most suitable for welding thick plates and copper stranded cable, as it can adjust the weld time through a wider range than other stored energy type of welders. The lower peak current is less affected by dirt or stain on the work piece. These are very suitable for integration with automation. AIT builds all of our own electrodes for use in these and other welders that we provide to our customers. We can provide custom electrodes and solutions for your welding applications.

Suitable weld heads and other accessories are available for all the welders featured below. It is best to contact us and describe your welding application in detail, and allow our technician to work with you in determining the best power supply, weld head, and electrodes for your specific applications.

| AVIO single phase AC spot welding power supplies | |||

| Features | NRW-5A | NRW-25A | |

| Control System | Synchronized | ||

| Range of Heat Control | 40 - 100% | ||

| Welding Time | 0.5 - 99 cycles | ||

| Squeeze, Hold Time | 0 - 99 cycles | ||

| Welding Function | pre-heating, up slope, cool time, channel switching function | ||

| Rated Capacity | 3KVA (50% duty) | 6KVA (50% duty) | |

| 9.5KVA (5% duty) | 19KVA (5% duty) | ||

| Power Source | 200V AC +/-10% 50/60Hz (optional 100-120V AC) | ||

| AC Welding Power Supplies | |

| NRW-5A | NRW-25A |

|

|

AC Welding Transformers

NT-5A

| AVIO Welding Transformers | |||

| Features | NT-5A | ||

| Primary Input Voltage | 200V | ||

| Rated Input Capacity (duty cycle 50%) | 3KVA | ||

| Secondary Short-circuit Current | 5000A | ||

| Secondary Open-circuit Voltage | 1.1, 1.8, 2, 5 (V) | ||

AC Welding Transformers

NT-8A

| AVIO Welding Transformers | |||

| Features | NT-8A | ||

| Primary Input Voltage | 200V | ||

| Rated Input Capacity (duty cycle 50%) | 6KVA | ||

| Secondary Short-circuit Current | 11000A | ||

| Secondary Open-circuit Voltage | 1.8, 3, 5 (V) | ||

AC Welding Transformers

NT-5M

| AVIO Welding Transformers | |||

| Features | NT-5M | ||

| Primary Input Voltage | 200V | ||

| Rated Input Capacity (duty cycle 50%) | 2.8KVA | ||

| Secondary Short-circuit Current | 2400A | ||

| Secondary Open-circuit Voltage | 6, 6.5, 7, 7.5 (V) | ||

| AVIO Step Down Transformers | ||

| Features | ST-100 | ST-200 |

| Primary Input Voltage | 115V / 230V | 220V / 230V |

| Rated Input Capacity | 1KVA | 6KVA |

| Secondary Open-circuit Voltage | 100V | 200V |

Sunstone Welders

These AC spot welders make use of an internal transformer that provides ample power for many applications, making them ideal for resistance spot welding and seam welding. Both of these welders also make use of a microprocessor that allows easy setup and programming for complex welding sequences, such as linking different weld schedules together within the same job. Either of these AC spot welders are capable of welding thicknesses up to 0.1 inch.

Advanced Modes:

- Dual Pulse Welding

- Multi-pulse Welding

- Seam Roll Spot Welding

- Seam Welding

- Temper Function

The seam welding function of these AC welders make them very popular. The internal micro controller allows for complex seam welding sequences.

Click here for matching weld heads.

1.5kVA and 2.5kVA AC Resistance Spot Welders

Features:

- Simple, User-Friendly Interface

- 110 V Single Phase

- Internal AC Transformer

- 4 Line Character Display

- Foot Pedal

- Single Pulse, Dual Pulse, Multi Pulse, Seam, and Rolling Spot Modes

- Up To 180 Welds per Minute

- Pulse length range excluding seam weld mode ( 16.67ms to 1.65 sec )

- Save up to 100 Programmable Schedules

- Size: 13.25" x 10" x 5.5" - 32 lbs

- Possible Applications: Brazing, battery pack assembly, resistance seam welding, resistance soldering, and general resistance welding.

|

||

|

|

|

| Features of each Sunstone power supply | 1.5 kVa AC Spot Welder | 2.5 kVa AC Spot Welder |

| Internal Transformer Rating | 1.5 kVa | 2.5 kVa |

| Welding Duty Cycle | 50% | 50% |

| Total Number of Savable Schedules | 100 | 100 |

| Maximum Internal Operating Temperature | 75 °C | 75 °C |

| Fuse Rating | 20A | 20A |

| Power Supply Requirements | 110-120VAC 50-60Hz | 110-120VAC 50-60Hz |

| Weight | 31 lbs (14 kg) | 32 lbs (14 kg) |

| Case Dimensions (L x W x H without terminals, with feet) | 13.25” x 10” x 5.5” | 13.25” x 10” x 5.5” |

| Minimum Pulse Length | 16.67 ms | 16.67 ms |

| Maximum Pulse Length (excluding seam mode welding) | 1.65 sec | 1.65 sec |

| Maximum Welds Per Minute | 180 | 180 |

2.2kVA and 5kVA AC Resistance Spot Welders

| Features of each Sunstone power supply | 2.2 kVa AC Spot Welder | 5 kVa AC Spot Welder |

| Primary Volts | 110/220/240 | 240 |

| Max Weld. Cap. (PG2) | 2 x 0.5 | 2 x 0.75 |

| Short Circuit Current | 2100A | 2500A |

| Open Circuit Volts | 4.5V | 5.8V |

| Weight | 44 lbs (20kg) | 105 lbs (48kg) |

| Dimensions | 14″x10.25″x13″ | 21.25″x12.6″x13.4″ |

Provide you with Battery Tab Welders with Advanced Welding Functions as well as low cost solutions.

![]() Welders designed for superior battery tab welding

Welders designed for superior battery tab welding![]() Lower prices on equipment and electrodes than other manufacturers

Lower prices on equipment and electrodes than other manufacturers![]() Shorter lead time, especially on electrodes

Shorter lead time, especially on electrodes![]() Free test welds and unparalleled customer support

Free test welds and unparalleled customer support

How We Can Help You

The best way to get the correct battery tab welder is to discuss your application with us and allow us to perform a free test weld to determine which welder/transformer combination is best for your applications. We are an equipment and technical support provider for Nippon Avionics ( Avio ) brand of hybrid battery tab welders. We also offer both Avio and Sunstone brands of capacitive discharge welders which are suitable for battery tab welding, although with less advanced functions than the hybrid battery tab welder. At AIT, we have chosen the Nippon Avionics ( AVIO ) line of equipment because we have found that you get more advanced technology, quality, and precision for your money than with other popular brands. We can provide the equipment you need at an economical price, and assist with any technical issues you encounter setting up your welding process. Submit a contact form or call us today to request assistance with your next project.

AVIO Battery Tab Welder.

-

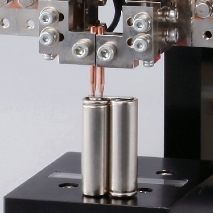

Designed for series welding of battery tabs without damaging battery cells

-

Fast rising time equaling less thermal damage

-

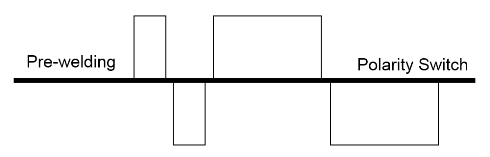

Polarity switch function leading to uniform welds and longer electrode life

-

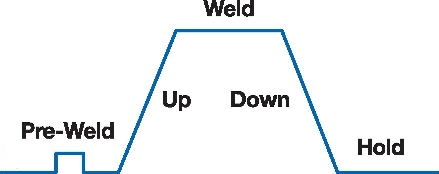

4 pulse wave form with pre-weld

-

Automatic weld stop function to preven over energy welds

-

LCD graph of welding wave form

Click here for matching weld heads.

| Features | Specifications | |

| Welding Power Supply | NRW-PS300 | |

| Welding Transformer | NT-PS300 | |

| Control Method | IGBT Control (Polarity Switch) | |

| Secondary Short-Circuit Current | 8000A | |

| Maximum Output Power | 300ws | |

| Setting Range | Weld Time | total 0.0 - 60.0ms |

| Transformer Tap | 2.5V, 5.0V, 7.1V, 10.0V | |

| Number of Condition | 63 | |

| Monitoring | V, I, W, R (Average, Peak) ws (phase shift) | |

| I/O Interface | I/O Connector (50pin), EXT_I/O (12pin) | |

| Communication | RS232C | |

| Power Source | 380-415V AC +/-10% | |

Effect of Polarity Switch Function

Without

With

Various welding modes for stable welding

Example of 4 pulse welding schedule

Battery Pack Welding

Transformer NT-PS300 & Power Supply NRW-PS300

Graphic Display of Welding Wave Form

| Other Transformer Options | ||

| Features | NT-PS1500 | NT-PS1500H |

| Secondary Short-Circuit Current | 8000A | 8000A |

| Maximum Output Power | 1500 ws | 1500 ws |

| Transformer Tap | 2.5V, 5.0V, 7.1V, 10.0V | 10.0V, 14.1V, 20.0V, 28.3V |

| Weight | 52kG | 53kG |

AIT offers the AVIO line of ultra precision Transistor Welders

![]() Providing you with equipment and technical support

Providing you with equipment and technical support

![]() Lower prices on equipment and electrodes than other manufacturers

Lower prices on equipment and electrodes than other manufacturers

![]() Shorter lead time, especially on electrodes

Shorter lead time, especially on electrodes

![]() Free test welds and unparalleled customer support

Free test welds and unparalleled customer support

Click here for matching weld heads.

How We Can Help You

The best way to start shopping for a welder is to take advantage of our free test welds to help determine if a transistor welder is the proper weld equipment for your application. We are an equipment and technical support provider for Nippon Avionics ( Avio ) brand of precision inverter welders. At AIT, we have chosen the Nippon Avionics ( AVIO ) line of equipment because we have found that you get more advanced technology, quality, and precision for your money than with other popular brands. We can provide the equipment you need at an economical price, and assist with any technical issues you encounter setting up your welding process. Submit a contact form or call us today to request assistance with your next project.

AVIO Transistor Welders

-

The favorite for welding micro wires and components

-

Consistent and precise welding by high speed linear control

-

3 Feedback modes (constant current, voltage, or power)

-

High speed welding (up to 5 shots / second)

-

Pre-weld check function reduces spark problems

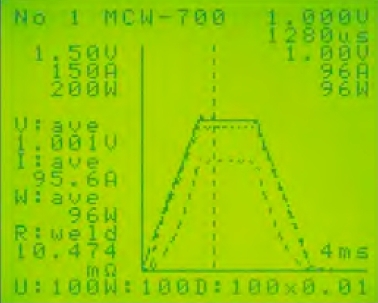

- Simultaneous graph of voltage, current, and power wave forms

| Features | MCW-700 | MCW-750 |

| Maximum Current | 500A | 1800A |

| Maximum Voltage | 2V | 4V |

| Constant Current Mode | 10 - 500A (1A Step) | 10 - 1800A (1A Step) |

| Constant Voltage Mode | 0.001 - 2V (1mV Step) | 0.01 - 4V (10mV Step) |

| Constant Power Mode | 10 - 500W (1W Step) | 10 - 3600W (1W Step) |

| Weld Time : Up | 0 -999 x 0.01ms or x 0.1ms | |

| Weld Time : Weld | 0 -999 x 0.01ms or x 0.1ms | |

| Weld Time : Down | 0 -999 x 0.01ms or x 0.1ms | |

| Weld Time : Squeeze&Hold | 9.99s (maximum) | 9.99s (maximum) |

| Pre-Check | Resistance/Current | Resistance/Current |

| Shot / Sec | 5shots / sec: 500W 2ms | 5 shots / sec : 3600W 2ms |

| Monitor : Wave Form | Current / Voltage / Power | Current / Voltage / Power |

| Monitor : Current | Average / Peak | Average / Peak |

| Monitor : Voltage | Average / Peak | Average / Peak |

| Monitor : Power | Average / Peak | Average / Peak |

| Number of Conditions | 15 | 15 |

| Interface | RS-232, I/O, analog output | RS-232, I/O, analog output |

| Power Source (Option) | 100-120V AC (200-240V AC) | 100-120V AC (200-240V AC) |

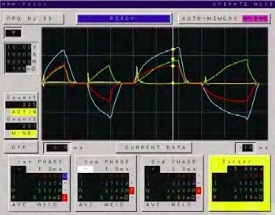

Real Time Welding Wave Form Display

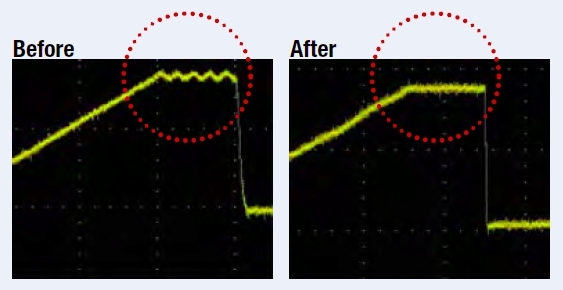

PID Adjustment - Before and After

Transistor welders are also known as Linear DC welders. In a transistor welder, energy is stored up in capacitors and released through transistors. This produces a result similar to the high frequency inverter power supplies. The output is in the form of clean square waves with very fast rise time. The transistor welders made by AVIO are closed loop designs, utilizing transistor controlled feedback with extremely fast response time, which are able to monitor the condition of the weld using one of three feed back modes, "constant current", "constant voltage", or "constant power". These feedback modes offer great advantages such as better process consistency between multiple weld stations, reduced number of bad welds, and real time automatic adjustment for variations in part thermal loading and plating. Linear DC welders do not use a transformer. These power supplies have the best low energy control, making them the favorite for welding micro wires and then foils. The major limitation is that the duty cycle is typically much less than one weld per second.

The Avio welders we are offering here are premium quality Japanese made welders. We stand by these welders and guarantee our customers support and assistance when you buy an Avio welder from us. All electrodes are manufactured by AIT in our facility in the United States. We can respond quickly to your inquiries or questions.

Welding Wave Form

SUNSTONE LINEAR DC WELDERS

AIT offers the AVIO line of quality high speed Inverter Welders

![]() Providing you with equipment and technical support

Providing you with equipment and technical support

![]() Lower prices on equipment and electrodes than other manufacturers

Lower prices on equipment and electrodes than other manufacturers

![]() Shorter lead time, especially on electrodes

Shorter lead time, especially on electrodes

![]() Free test weldsand unparalleled customer support

Free test weldsand unparalleled customer support

How We Can Help You

Advanced Integrated Technologies ( AIT ) offers you free test welds to help determine if an inverter welder is the proper equipment for your application. We are a equipment and technical support provider for Nippon Avionics ( Avio ) brand of precision inverter welders. At AIT, we have chosen the AVIO line of equipment because you get more advanced technology, quality, and precision for your money than with other popular brands. We can provide the equipment you need at an economical price, and assist with any technical issues you encounter setting up your welding process. Submit a contact form or call us today to request assistance with your next project.

Click here for matching weld heads.

AVIO Inverter Welders

-

High speed and precise control of wave form

-

3 Feedback modes (constant current, voltage, or power)

-

Pre-weld check function

-

Up to 3 second weld time

-

LCD graphic display of welding wave form

-

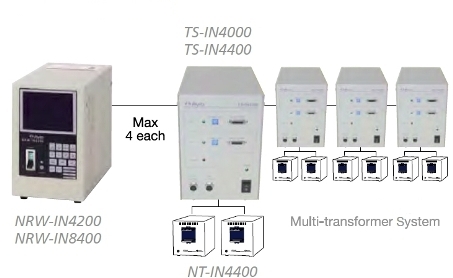

Multi Transformer System

Multi-transformer System

Graphic Display of Welding Waveform

| Features | NRW-IN4200 | NRW-IN8400 |

| Welding Transformer | NT-IN4400 | NT-IN8400 / NT-IN4400 |

| Maximum Current | 4000A | 8000A / 4000A |

| Control Frequency | 2KHz | |

| Control Mode | Constant Current, Voltage, or Power. Fixed Pulse Width | |

| Range of Timer Setting | Pre, 1st, 2nd, UP, WELD, DOWN | |

| Total Time 0.5 - 3000ms | ||

| Setting Range for Weld Type | Current 0.4 - 4.1KA | Current 0.4 - 8.2kA / 0.4 - 4.1kA |

| Voltage 0.4 - 4.1V | Voltage 0.4 - 6.2V / 0.4 - 4.1V | |

| Power 0.2 - 8.2kW | Power 0.2 - 24.5kW / 0.2 - 8.2kW | |

| Current/Voltage/Power, Resistance Monitoring | Average/Peak/Profile | |

| Trace Monitoring | Current, Voltage, Power, Resistance | |

| Display of Wave Form | Current, Voltage, Power, Resistance | |

| Number of Condition | 31 | |

| Interface | RS232C | |

| Power Source | 200-230 V AC | 380-415V AC / Optional 200-230 V AC |

Welding power supplies come in two broad categories, "closed loop" and "open loop". Open loop designs are capacitive discharge welders and most direct energy, or AC power supplies. These essentially offer no feedback, meaning that a weld command or pulse is sent out, but there is no circuitry to verify how that pulse responds when it hits the point of welding. Closed loop welders are inverter type (high frequency inverter) and transistor type (linear DC) welders. These type of welders are able to control the shape of the welding wave form and monitor the condition of the weld using one of three feed back modes, "constant current", "constant voltage", or "constant power". These feed modes offer great advantages such as better process consistency between multiple weld stations, reduced number of bad welds, and real time automatic adjustment for variations in part thermal loading and plating.

Inverter welders use pulse width modulation to control weld energy. Through a series of rectifiers and switches, the resulting output current is in the form of DC current with an imposed low-level AC ripple. The time of each piece of a cycle can be controlled in sub millisecond increments. Inverter welders have high repetition rates, making them particularly useful in industrial automation.

The Avio welders we are offering here are premium quality Japanese made high frequency inverter welder. We stand by these welders and guarantee our customer support and assistance when you buy an Avio welder from us. All electrodes are manufactured by AIT in our facility in the United States. We can respond quickly to your needs and build custom electrodes to help resolve any welding issues you encounter. Contact us today to see how AIT can make your next welding project a success.

Pulse Arc Welder

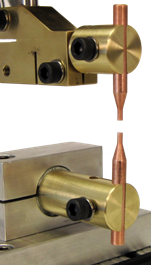

Male Cap Electrodes

Female Cap Electrodes

The Sunstone welder is an American made welder of good quality and good customer support. Sunstone manufactures capacitive discharge spot welders, AC welders, and pulse arc welders. A good selection of Sunstone products are listed on this page, and you can request a quote for any of this by calling us or submitting a contact form. Please note that all Sunstone equipment prices are fixed by the manufacturer. Although we are not allowed to discount the price of the welder, we can offer other discounts on shipping and electrodes if you purchase from us. If you are shopping for weld equipment, take advantage of our free test weld offer. We can evaluate your product samples, perform a variety of weld tests, and recommend the best equipment for your application.